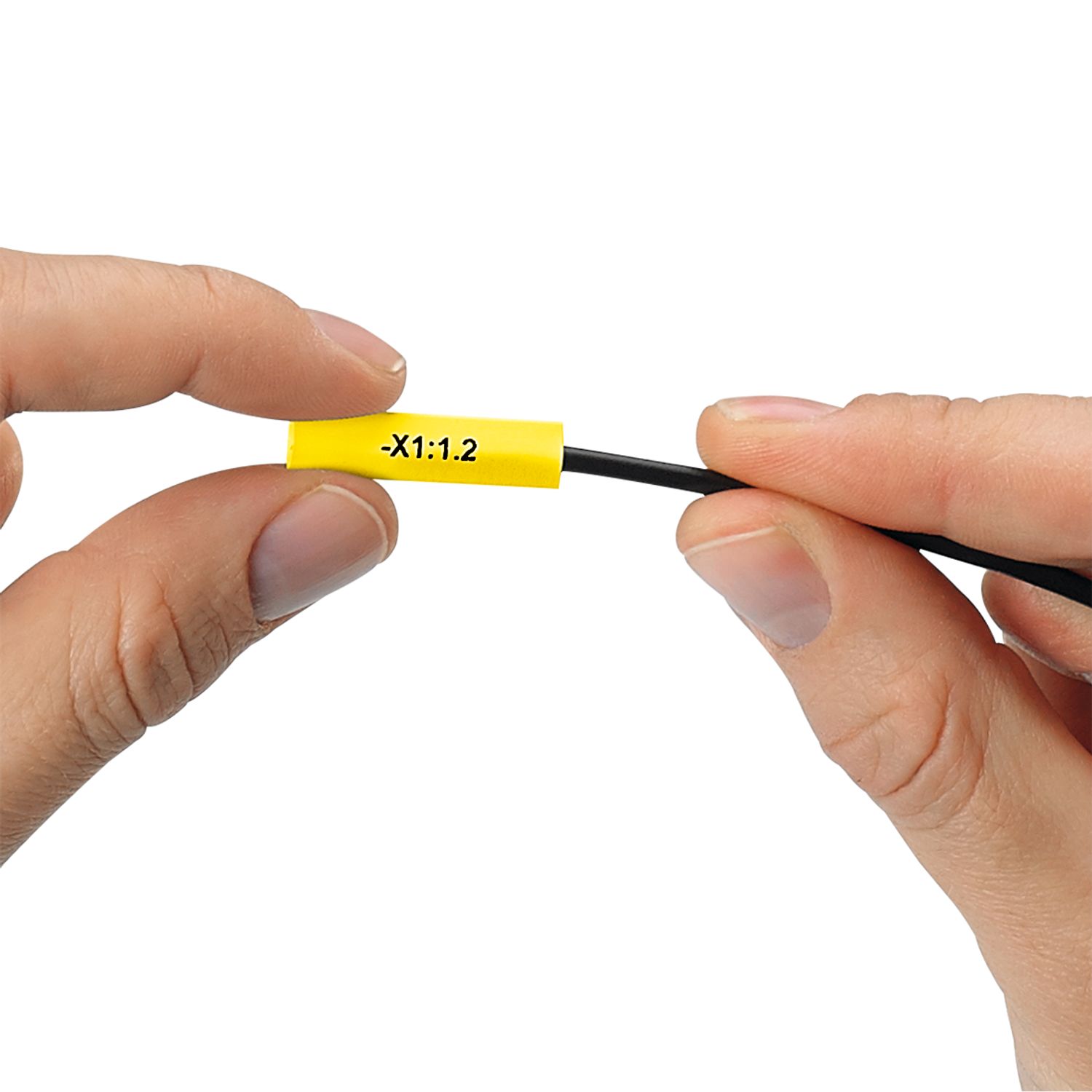

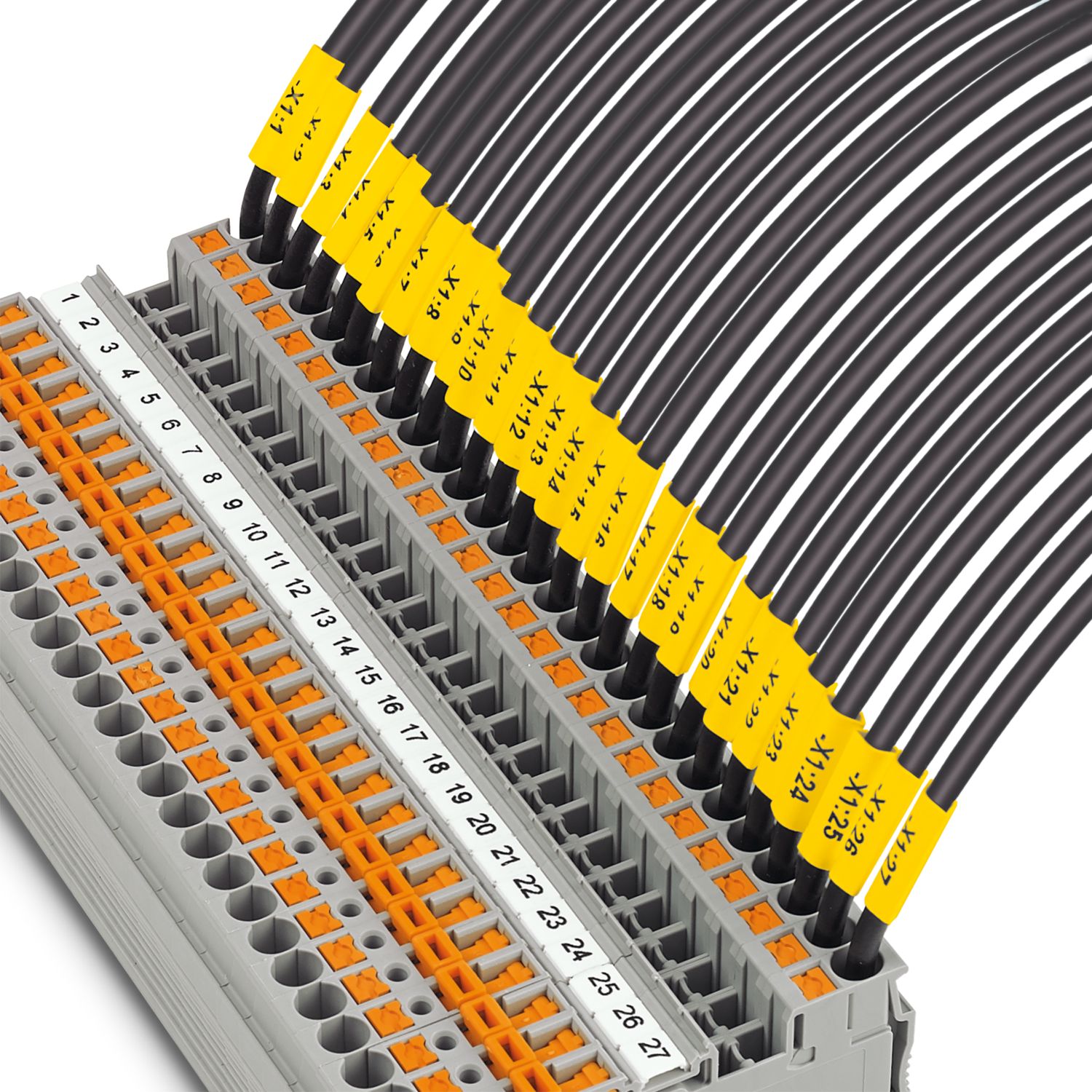

The continuous shrink sleeves in the WMS-2 HF... product family, in size 3.2 ... 9.5, are suitable for automated processing with the THERMOMARK E.SLEEVE applicator. The continuous format of the material means that individual marker lengths can be realized. After the printing and applying process, you have the option of shrinking the marked shrink sleeves by applying heat manually and thus fixing them on the cable/wire.