PTDA 1,5/ 2-3,5 GY

-

PCB terminal block

1215545

Printed circuit board terminal, nominal current: 17.5 A, rated voltage (III/2): 240 V, nominal cross section: 1.5 mm2, number of rows: 1, number of positions per row: 2, product range: PTDA 1,5/, pitch: 3.5 mm, connection method: Push-in spring connection, mounting: Wave soldering, conductor/PCB connection direction: 45 °, color: gray, Pin layout: Linear pinning, Solder pin [P]: 3.5 mm, number of solder pins per potential: 2, type of packaging: packed in cardboard

Detalii despre produs

| Product type | Printed circuit board terminal |

| Product family | PTDA 1,5/ |

| Product line | COMBICON Terminals S |

| Number of positions | 2 |

| Pitch | 3.5 mm |

| Number of rows | 1 |

| Pin layout | Linear pinning |

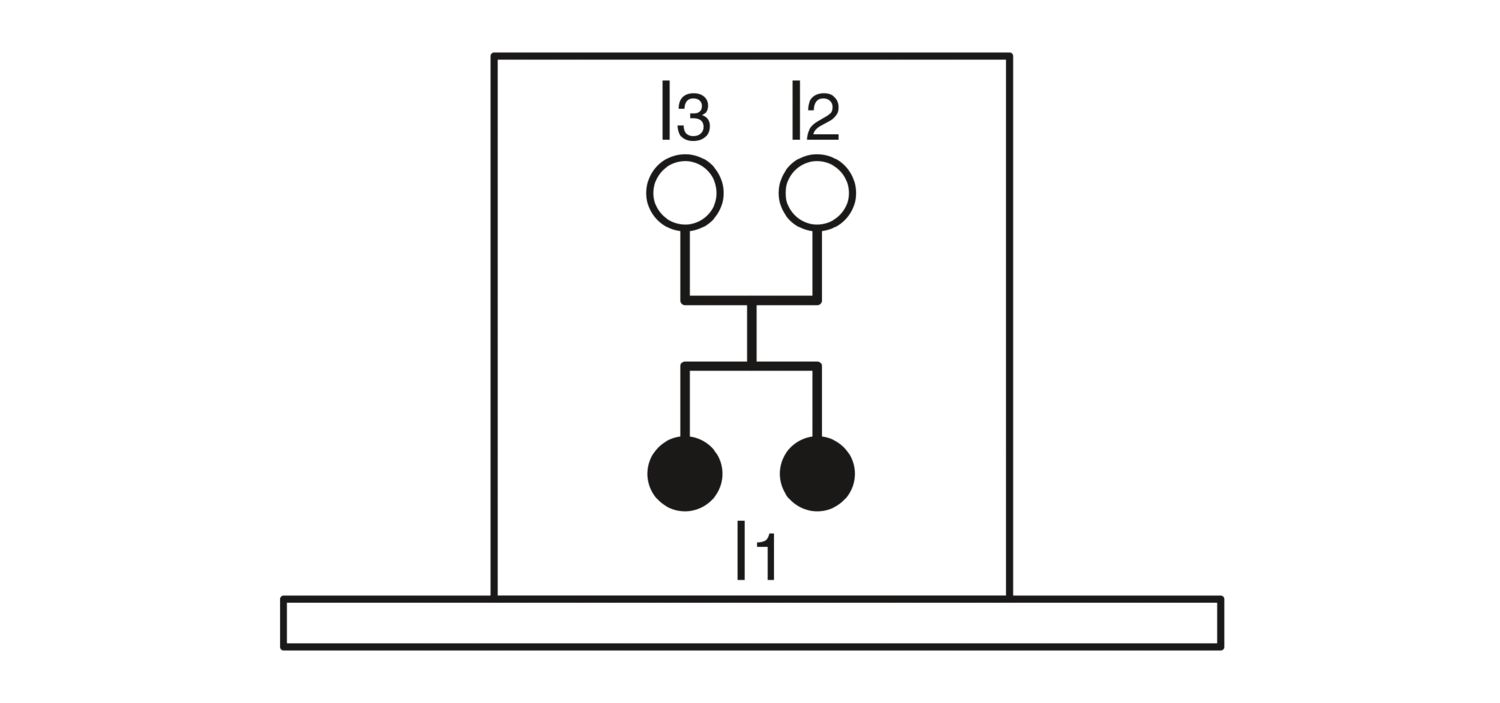

| Solder pins per potential | 2 |

| Properties | |

| Nominal current IN | 17.5 A |

| Nominal voltage UN | 240 V |

| Rated voltage (III/3) | 200 V |

| Rated surge voltage (III/3) | 2.5 kV |

| Rated voltage (III/2) | 240 V |

| Rated surge voltage (III/2) | 2.5 kV |

| Rated voltage (II/2) | 400 V |

| Rated surge voltage (II/2) | 2.5 kV |

| Connection technology | |

| Nominal cross section | 1.5 mm² |

| Conductor connection | |

| Connection method | Push-in spring connection |

| Conductor cross section rigid | 0.2 mm² ... 1.5 mm² |

| Conductor cross section flexible | 0.2 mm² ... 1.5 mm² |

| Conductor cross section AWG | 24 ... 16 |

| Conductor cross section flexible, with ferrule without plastic sleeve | 0.5 mm² ... 1.5 mm² |

| Conductor cross section, flexible, with ferrule, with plastic sleeve | 0.5 mm² ... 0.5 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 0.5 mm² |

| Stripping length | 10 mm |

| Mounting type | Wave soldering |

| Pin layout | Linear pinning |

| Material data - contact | |

| Note | WEEE/RoHS-compliant, free of whiskers according to IEC 60068-2-82/JEDEC JESD 201 |

| Contact material | Cu alloy |

| Surface characteristics | Tin-plated |

| Metal surface terminal point (top layer) | Tin (4 - 8 µm Sn) |

| Metal surface soldering area (top layer) | Tin (4 - 8 µm Sn) |

| Material data - housing | |

| Color (Housing) | gray (7042) |

| Insulating material | PA |

| Insulating material group | I |

| CTI according to IEC 60112 | 600 |

| Flammability rating according to UL 94 | V0 |

| Glow wire flammability index GWFI according to EN 60695-2-12 | 850 |

| Glow wire ignition temperature GWIT according to EN 60695-2-13 | 775 |

| Temperature for the ball pressure test according to EN 60695-10-2 | 125 °C |

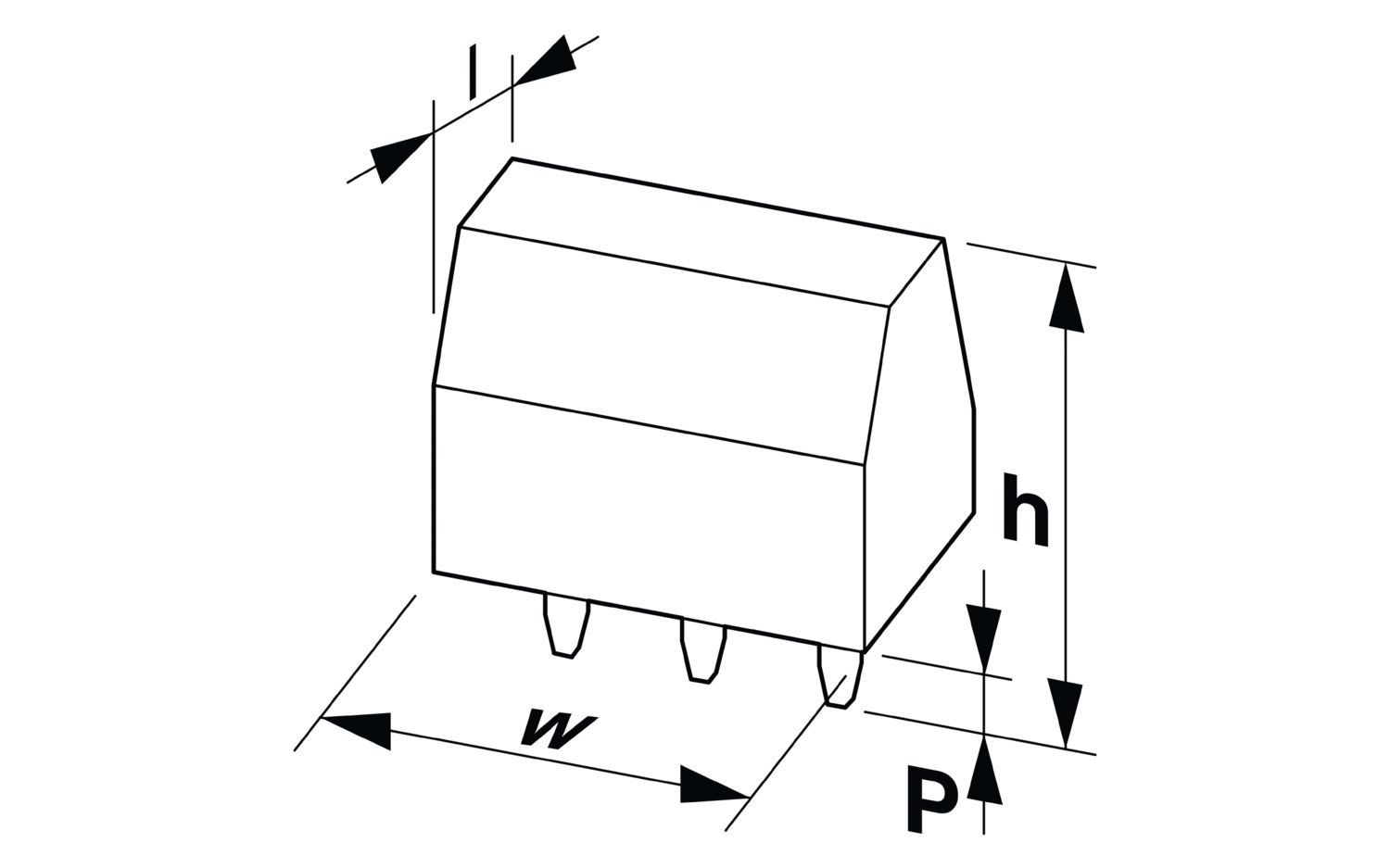

| Dimensional drawing |

|

| Pitch | 3.5 mm |

| Width [w] | 8.4 mm |

| Height [h] | 19.5 mm |

| Length [l] | 16 mm |

| Installed height | 16 mm |

| Solder pin length [P] | 3.5 mm |

| Pin dimensions | 1 x 0.4 mm |

| PCB design | |

| Pin spacing | 3.5 mm |

| Hole diameter | 1.3 mm |

| Connection test | |

| Specification | IEC 60998-2-2:2002-12 |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Specification | IEC 60998-2-2:2002-12 |

| Result | Test passed |

| Pull-out test | |

| Specification | IEC 60998-2-2:2002-12 |

| Conductor cross section/conductor type/tractive force setpoint/actual value | 0.2 mm² / solid / > 10 N |

| 0.2 mm² / flexible / > 10 N | |

| 1.5 mm² / solid / > 40 N | |

| 1.5 mm² / flexible / > 40 N | |

| Flexion test | |

| Specification | IEC 60998-2-2:2002-12 |

| Result | Test passed |

| Temperature-rise test | |

| Specification | IEC 60947-7-4:2019-01 |

| Requirement temperature-rise test | The sum of ambient temperature and temperature rise of the PCB terminal block shall not exceed the upper limiting temperature. |

| Insulation resistance | |

| Specification | IEC 60998-1:2002-12 |

| Insulation resistance, neighboring positions | > 5 MΩ |

| Air clearances and creepage distances | | |

| Specification | IEC 60664-1:2007-04 |

| Insulating material group | I |

| Comparative tracking index (IEC 60112) | CTI 600 |

| Rated insulation voltage (III/3) | 200 V |

| Rated surge voltage (III/3) | 2.5 kV |

| minimum clearance value - non-homogenous field (III/3) | 1.5 mm |

| minimum creepage distance (III/3) | 2.5 mm |

| Rated insulation voltage (III/2) | 240 V |

| Rated surge voltage (III/2) | 2.5 kV |

| minimum clearance value - non-homogenous field (III/2) | 1.5 mm |

| minimum creepage distance (III/2) | 1.25 mm |

| Rated insulation voltage (II/2) | 400 V |

| Rated surge voltage (II/2) | 2.5 kV |

| minimum clearance value - non-homogenous field (II/2) | 1.5 mm |

| minimum creepage distance (II/2) | 2 mm |

| Vibration test | |

| Specification | IEC 60068-2-6:1995-03 |

| Frequency | 10 - 150 - 10 Hz |

| Sweep speed | 1 octave/min |

| Amplitude | 0.35 mm (10 Hz ... 60.1 Hz) |

| Acceleration | 5g (60.1 Hz ... 150 Hz) |

| Test duration per axis | 2.5 h |

| Test directions | X-, Y- and Z-axis |

| Glow-wire test | |

| Specification | IEC 60998-1:2002-12 |

| Temperature | 850 °C |

| Time of exposure | 5 s |

| Ambient conditions | |

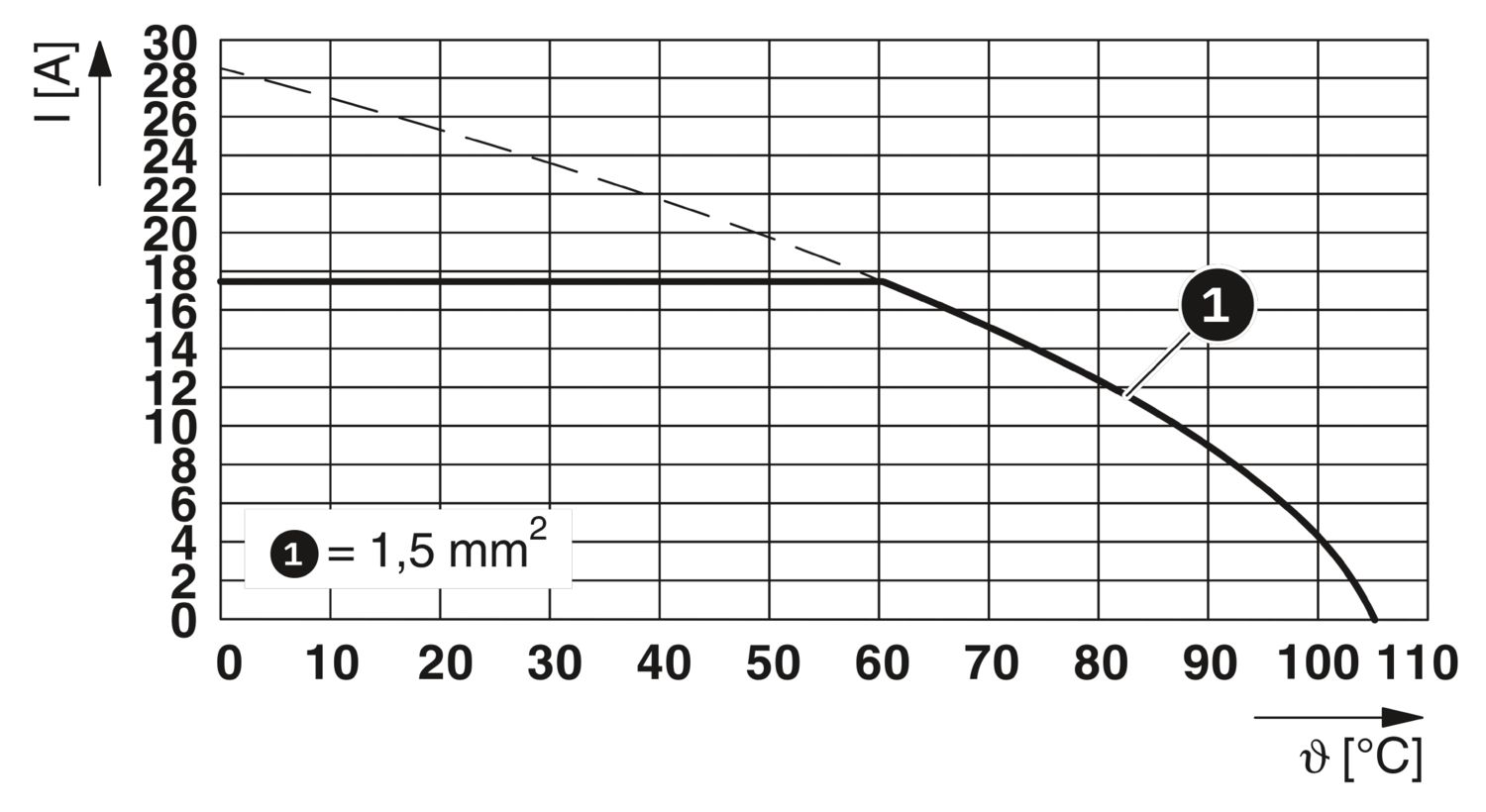

| Ambient temperature (operation) | -40 °C ... 105 °C (dependent on the derating curve) |

| Ambient temperature (storage/transport) | -40 °C ... 70 °C |

| Relative humidity (storage/transport) | 30 % ... 70 % |

| Ambient temperature (assembly) | -5 °C ... 100 °C |

| Type of packaging | packed in cardboard |

| Număr articol | 1215545 |

| Unitate de ambalare | 50 Bucată |

| Cantitate minimă pentru comandă | 1.000 Bucată |

| Indicație | Produs la comandă (nereturnabil) |

| Cod produs | AALBBA |

| GTIN | 4063151296315 |

| Greutate pe bucată (inclusiv ambalajul) | 2,806 g |

| Greutate pe bucată (fără ambalaj) | 2,568 g |

| Cod tarifar vamal | 85369010 |

| Țara de origine | PL |

ECLASS

| ECLASS-13.0 | 27460101 |

ETIM

| ETIM 9.0 | EC002643 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Îndeplineşte cerinţele conform directivei RoHS | Da (Nicio reglementare privind excepţiile) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

Nu există substanțe periculoase peste valorile limită

|

| EU REACH SVHC | |

| Trimitere la substanţa candidată REACH (nr. CAS) | Nicio substanţă cu un procentaj masic mai mare de 0,1 % |

Avantajele dumneavoastră

Time saving push-in connection, tools not required

Defined contact force ensures that contact remains stable over the long term

Potentials can be easily looped through – ideal for BUS applications

Quick and convenient testing using integrated test option

Rounded type for individual device design

Two solder pins reduce the mechanical strain on the soldering spots