EN IEC 62061 updated

Due to harmonization with the Machinery Directive 2006/42/EC, EN IEC 62061 is an important tool for the design of functional safety.

In order to implement the requirements of Annex I (Section 1.2.1), the standard was recently revised, which has led to some changes.

Technologies are developing faster than ever.

It is therefore essential that standards and directives also adapt to state-of-the-art technology and move with the times.

A lot is currently happening in machine building.

Instead of the Machinery Directive currently in force, the new Machinery Regulation will be adopted soon.

The transition period between the two sets of regulations is expected to be 42 months. In the area of functional safety, both EN IEC 62061 and EN ISO 13849-1 have been scrutinized.

The updated version of EN IEC 62061 has been available in English since September 2022.The existing DIN EN 62061 could still be used for conformity until November 11, 2023.

Selection and assessment of safety-related control components:

The Machinery Directive 2006/42/EC requires a risk assessment to be carried out. EN ISO 12100 provides various aids to ensure that the essential health and safety requirements from Annex I of the directive can be implemented.

Constructive, technical, and informative measures can be defined during the risk assessment.

This reliability must be determined and evaluated for each component that performs a safety function to safeguard against a risk.

In this area of functional safety, EN IEC 62061 and EN ISO 13849 support the manufacture.

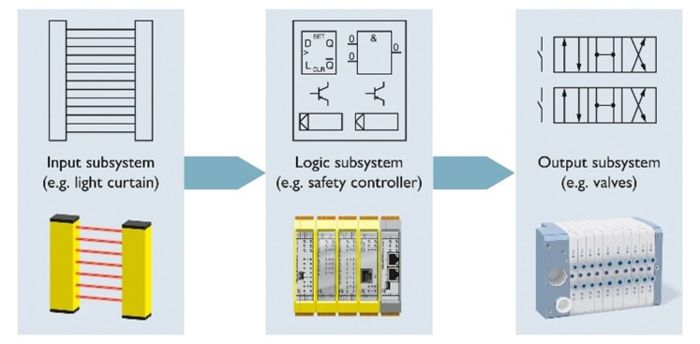

Examples of the components of a safety function.

Both EN ISO 13849 and EN IEC 62061 are derived from EN 61508. They can therefore be used equally for the selection and assessment of safety-related control components.

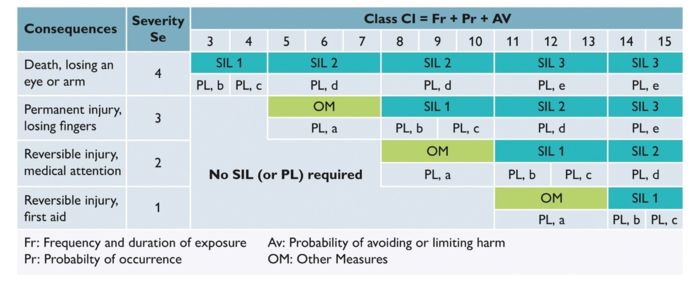

As a result, both standards provide a parameter that can be used to describe the quality of safety functions or individual components.

EN ISO 13849 uses the familiar performance level (PL) as a parameter, while EN IEC 62061 specifies the safety integrity level (SIL).

Both parameters can be equated using a correlation table, as the PFH(D) value (probability of a dangerous failure per hour) is used as the basis in each case.

The parameters PL and SIL can be equated using a correlation table: “A.6: Matrix assignment for determining the required SIL or PLr”

What was previously only known from EN ISO 13849 with regard to the safety of machinery will also apply to EN IEC 62061 in the future:

In addition to electrical/electronic systems, mechanical, pneumatic, and hydraulic systems will also be considered and assessed with a SIL.

The following relevant aspects of EN IEC 62061 have been revised:

- A new addition is Annex C “Typical failure rates of components (method according to good engineering practice)”.

- Annex D, which provides examples of diagnostic coverage, has also been added.

- Annex E on CCF (common cause failure) measures has been extended.

- New requirements are being placed on the application software.

- EMC requirements have been added.

- The requirements for periodic tests have also been expanded.

- The term “security” has been introduced.

- The topic of overlapping hazards has been included for the first time.

The main changes are explained in more detail below:

- Software level for safe application software:

The term software level is newly introduced in EN IEC 62061.

If the user uses safe software, this must also meet the requirements for a SIL. Depending on its complexity, the software is assigned to a software level, which in turn can be assigned to a SIL.

The software used in a safety function must undergo a SIL assessment in order for the safety function to achieve an overall SIL.

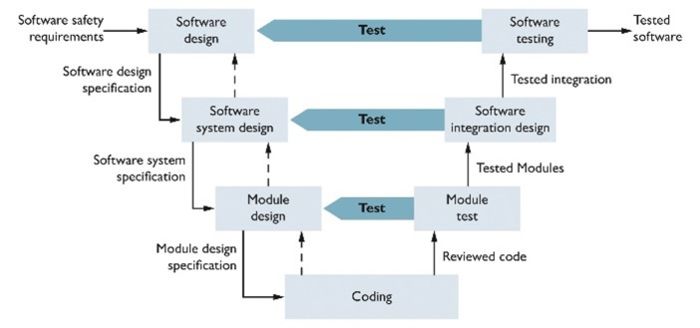

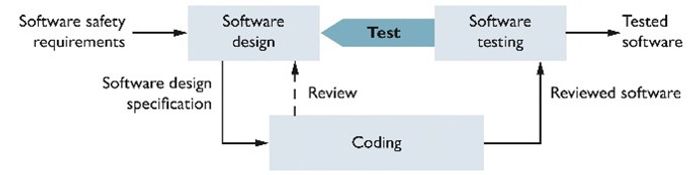

Furthermore, the V-model is introduced for the creation of software.

A comparable V-model has long been used for safe software in accordance with EN ISO 13849-1.

It shows the different development stages in the generation of software with the associated specification and verification steps in order to create planned and systematically tested software. Depending on the complexity of the software, it is also divided into different software levels.

• Software level for safe application software

Among other things, the V-model shows the different development stages in the generation of software:

This V-model is to be used for software levels 2 and 3.

The simplified V-model can be used for software level 1.

• Levels of independence for the verification and validation of software

What is also new is that those carrying out testing need levels of independence for the verification and validation of software.

Depending on the SIL to be achieved for the software, the person performing testing must in most cases be an “independent person”.

Depending on the requirements, independence can be ensured by an external test body or by the company’s own corporate structure.

• Examples for determining the diagnostic coverage

As in EN ISO 13849, EN IEC 62061 now lists a table containing example measures for determining the diagnostic coverage for components from safety functions.

Depending on the diagnostic measure used, the diagnostic coverage achieved can be seen in the table.

• Security considerations

With the new Machinery Regulation, the demand for measures to ensure the security of machinery is becoming more clearly defined.

The topic has now been included in EN IEC 62061, which underlines the shattering effect of access by malicious third parties.

As soon as security has an impact on functional safety systems, the aspects must be examined more closely.

EN IEC 62061 does not describe any specific measures, but merely points out that such aspects must be taken into consideration.

Instead, it refers to other standards – such as IEC 62443 – or technical rules.

• Convergence with EN ISO 13849

The original idea of merging EN ISO 13849 and EN IEC 62061 into one standard is no longer being pursued.

However, the two standards continue to converge.

This means that EN IEC 62061 can also be used for electrical/electronic, mechanical, pneumatic, and hydraulic systems in the future, and therefore no longer differs that greatly from EN ISO 13849 in terms of its area of application.

The content and references in EN IEC 62061 are also becoming increasingly similar. Their modifications now lead to more practical handling for machine manufacturers.

At a glance

- In the area of functional safety, both EN ISO 13849 and EN IEC 62061 can be used.

- The Phoenix Contact Services unit supports users in carrying out risk assessments and demonstrating safety integrity (including Sistema) on the basis of EN ISO 13849.

- Furthermore, the company’s experts are available to assist with the creation of a CE-compliant machine – including documentation, verification and validation, and operating instructions as an option.