MKDSO 2,5/ 3-R BU VPE100

-

PCB terminal block

2853860

Printed circuit board terminal, nominal current: 24 A, rated voltage (III/2): 400 V, nominal cross section: 2.5 mm2, number of rows: 1, number of positions per row: 3, product range: MKDSO 2,5/..-R, pitch: 5 mm, connection method: Screw connection with tension sleeve, mounting: Wave soldering, conductor/PCB connection direction: 0 °, Pin layout: Linear pinning, Solder pin [P]: 3.5 mm, number of solder pins per potential: 1. Article with lateral pin exit

Докладно про виріб

| Product type | Printed circuit board terminal |

| Product family | MKDSO 2,5/..-R |

| Type | PCB termination block perpendicular to the PCB |

| Number of positions | 3 |

| Pitch | 5 mm |

| Number of rows | 1 |

| Pin layout | Linear pinning |

| Solder pins per potential | 1 |

| Properties | |

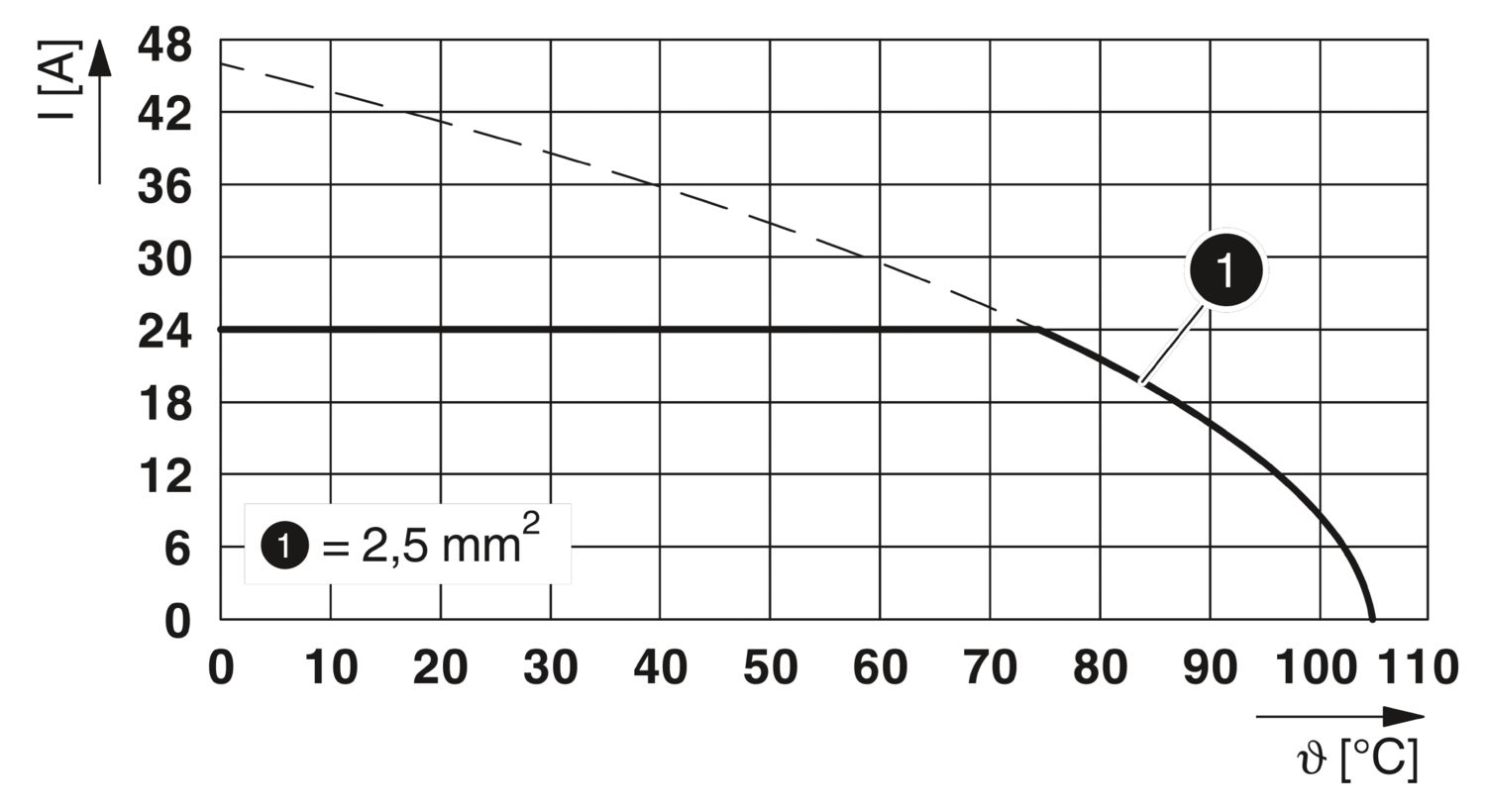

| Nominal current IN | 24 A |

| Nominal voltage UN | 400 V |

| Rated voltage (III/3) | 250 V |

| Rated surge voltage (III/3) | 4 kV |

| Rated voltage (III/2) | 400 V |

| Rated surge voltage (III/2) | 4 kV |

| Rated voltage (II/2) | 630 V |

| Rated surge voltage (II/2) | 4 kV |

| Connection technology | |

| Nominal cross section | 2.5 mm² |

| Conductor connection | |

| Connection method | Screw connection with tension sleeve |

| Conductor cross-section rigid | 0.14 mm² ... 2.5 mm² |

| Conductor cross-section flexible | 0.14 mm² ... 2.5 mm² |

| Conductor cross-section AWG | 26 ... 14 |

| Conductor cross-section flexible, with ferrule without plastic sleeve | 0.25 mm² ... 2.5 mm² |

| Conductor cross-section, flexible, with ferrule, with plastic sleeve | 0.25 mm² ... 2.5 mm² |

| 2 conductors with same cross section, solid | 0.14 mm² ... 0.75 mm² |

| 2 conductors with same cross section, flexible | 0.14 mm² ... 0.75 mm² |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 0.25 mm² ... 0.75 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 1.5 mm² |

| Stripping length | 8 mm |

| Tightening torque | 0.5 Nm ... 0.6 Nm |

| Mounting type | Wave soldering |

| Pin layout | Linear pinning |

| Material data - contact | |

| Note | WEEE/RoHS-compliant, free of whiskers according to IEC 60068-2-82/JEDEC JESD 201 |

| Contact material | Cu alloy |

| Surface characteristics | Tin-plated |

| Metal surface terminal point (top layer) | Tin (5 - 7 µm Sn) |

| Metal surface terminal point (middle layer) | Nickel (2 - 3 µm Ni) |

| Metal surface soldering area (top layer) | Tin (5 - 7 µm Sn) |

| Metal surface soldering area (middle layer) | Nickel (2 - 3 µm Ni) |

| Material data - housing | |

| Insulating material | PA |

| Insulating material group | I |

| CTI according to IEC 60112 | 600 |

| Flammability rating according to UL 94 | V0 |

| Glow wire flammability index GWFI according to EN 60695-2-12 | 850 |

| Glow wire ignition temperature GWIT according to EN 60695-2-13 | 775 |

| Temperature for the ball pressure test according to EN 60695-10-2 | 125 °C |

| Note on application | For reliable conductor connection, always adhere to a defined tightening torque. During conductor connection (mounting), the terminal blocks must be supported (held with one hand, support on the housing). |

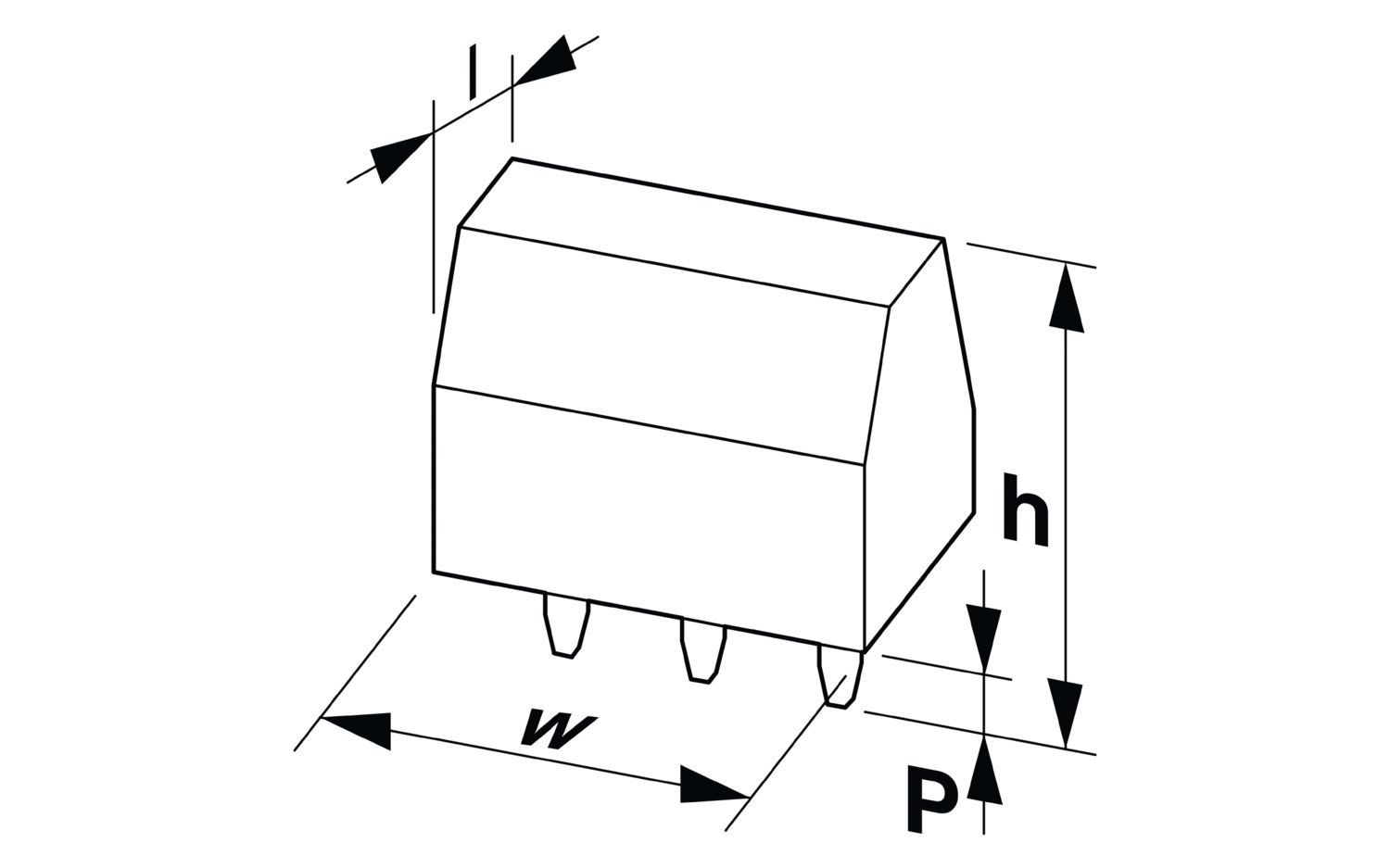

| Dimensional drawing |

|

| Pitch | 5 mm |

| Length [l] | 15.3 mm |

| Installed height | 18 mm |

| Solder pin length [P] | 3.5 mm |

| Pin dimensions | 0.8 x 1 mm |

| PCB design | |

| Hole diameter | 1.4 mm |

| Test for conductor damage and slackening | |

| Specification | IEC 60999-1:1999-11 |

| Result | Test passed |

| Pull-out test | |

| Specification | IEC 60999-1:1999-11 |

| Conductor cross-section/conductor type/tractive force setpoint/actual value | 0.14 mm² / solid / > 10 N |

| 0.14 mm² / flexible / > 10 N | |

| 2.5 mm² / solid / > 50 N | |

| 2.5 mm² / flexible / > 50 N | |

| Temperature-rise test | |

| Specification | IEC 60947-7-4:2019-01 |

| Requirement temperature-rise test | The sum of ambient temperature and temperature rise of the PCB terminal block shall not exceed the upper limiting temperature. |

| Short-time withstand current | |

| Specification | IEC 60947-7-4:2019-01 |

| Insulation resistance | |

| Specification | IEC 60512-3-1:2002-02 |

| Insulation resistance, neighboring positions | > 5 MΩ |

| Air clearances and creepage distances | | |

| Specification | IEC 60947-7-4:2019-01 |

| Insulating material group | I |

| Comparative tracking index (IEC 60112) | CTI 600 |

| Rated insulation voltage (III/3) | 250 V |

| Rated surge voltage (III/3) | 4 kV |

| minimum clearance value - non-homogenous field (III/3) | 3 mm |

| minimum creepage distance (III/3) | 3.2 mm |

| Rated insulation voltage (III/2) | 400 V |

| Rated surge voltage (III/2) | 4 kV |

| minimum clearance value - non-homogenous field (III/2) | 3 mm |

| minimum creepage distance (III/2) | 2 mm |

| Rated insulation voltage (II/2) | 630 V |

| Rated surge voltage (II/2) | 4 kV |

| minimum clearance value - non-homogenous field (II/2) | 3 mm |

| minimum creepage distance (II/2) | 3.2 mm |

| Vibration test | |

| Specification | IEC 60068-2-6:2007-12 |

| Frequency | 10 - 150 - 10 Hz |

| Sweep speed | 1 octave/min |

| Amplitude | 0.35 mm (10 Hz ... 60.1 Hz) |

| Acceleration | 5g (60.1 Hz ... 150 Hz) |

| Test duration per axis | 2.5 h |

| Test directions | X-, Y- and Z-axis |

| Glow-wire test | |

| Specification | IEC 60695-2-10:2013-04 |

| Temperature | 850 °C |

| Time of exposure | 5 s |

| Aging | |

| Specification | IEC 60947-7-4:2019-01 |

| Ambient conditions | |

| Ambient temperature (operation) | -40 °C ... 105 °C (Depending on the current carrying capacity/derating curve) |

| Ambient temperature (storage/transport) | -40 °C ... 55 °C |

| Relative humidity (storage/transport) | 30 % ... 70 % |

| Ambient temperature (assembly) | -5 °C ... 100 °C |

| Артикул | 2853860 |

| Пакувальна одиниця | 100 Шт. |

| Мінімальний обсяг замовлення | 1 Шт. |

| Вказівка | Виготовлення на замовлення (повернення неможливе) |

| Код виробу | ACHADA |

| GTIN | 4017918456481 |

| Маса штуки (з упаковкою) | 5,848 g |

| Маса штуки (без упаковки) | 5,08 g |

| Митний тарифний номер | 85369010 |

| Країна походження | DE |

Переваги

Maintenance-free and vibration-resistant, thanks to the Reakdyn principle or spring-loaded elements

PCB terminal block is orthogonal to the PCB

Internationally recognized and proven screw connection