WMTS (23X4)R

-

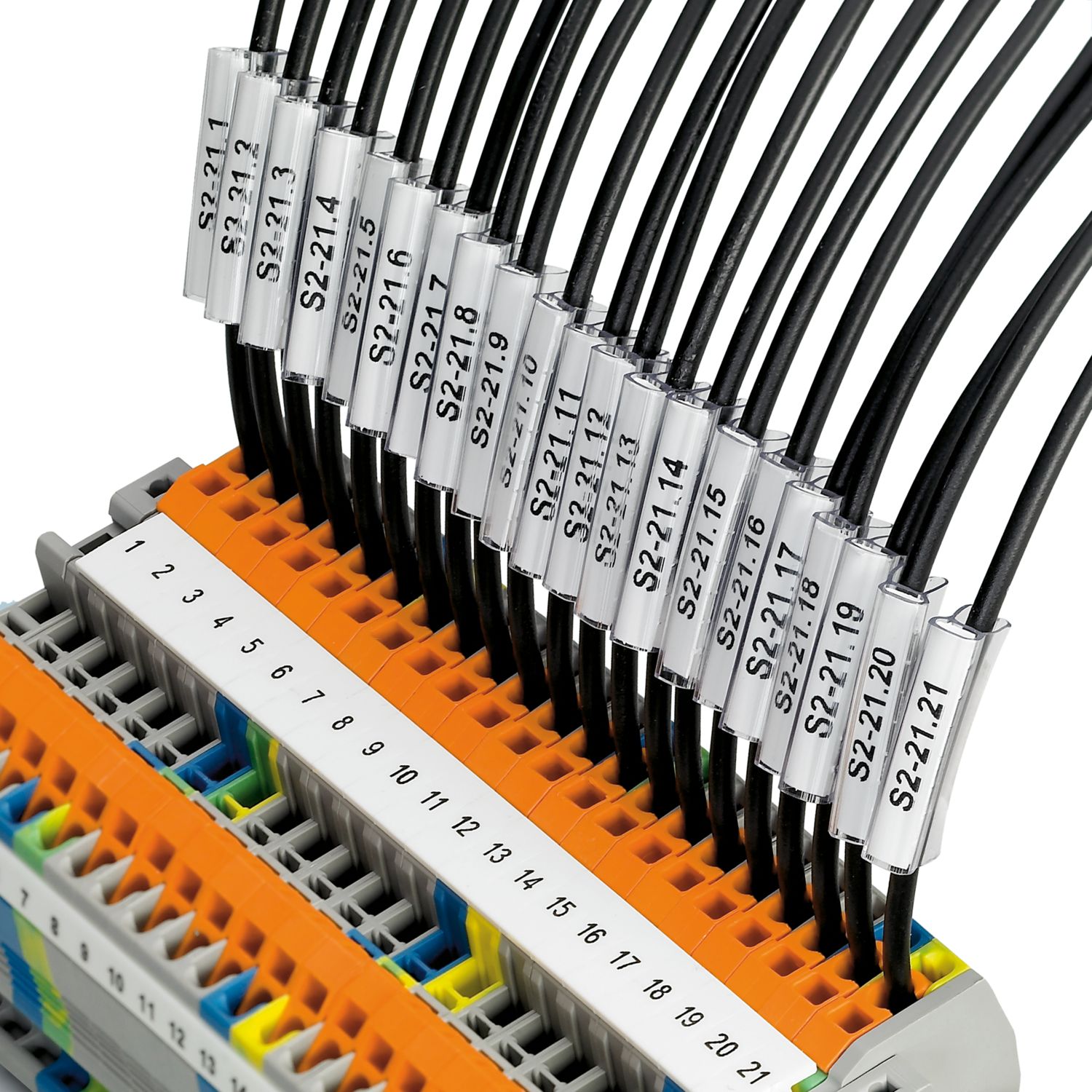

Cable marker

1352327

Cable marker, Roll, white, unmarked, can be labeled with: THERMOMARK E.300 (D)/600 (D), THERMOMARK ROLL 2.0, THERMOMARK ROLL, THERMOMARK ROLL X1, THERMOMARK ROLLMASTER 300/600, cable diameter range: 0.6 ... 45 mm, mounting type: insert, Number of individual labels: 3000, text field height: 4 mm, text field width: 23 mm

Detalhes dos produtos

| Marking | |

| Number of individual labels | 3000 |

| Number of individual labels per row | 1 |

| Identification technology | Thermotransfer |

| Width | 23 mm |

| Height | 4.5 mm |

| Depth | 0.3 mm |

| Text field | |

| Text field width | 23 mm |

| Text field height | 4 mm |

| Color | white (RAL 9010) |

| Material | PET |

| Base element material | Polyethylene terephthalate |

| Components | halogen-free |

| External cable diameter | 0.6 mm ... 45 mm |

| Test for substances that would hinder coating with paint or varnish | |

| Testing for paint wetting impairment substances (LABS-conformity) | VDMA 24364-A1-L:2018-05 |

| Result | Test passed |

| Scratch resistance | |

| Specification | EN ISO 1518-1:2023 (following) |

| Requirements | ≥ 5 N |

| Result | Test passed |

| Tesafilm test | |

| Specification | DIN EN ISO 2409:2020-12 (following) |

| Result | Test passed |

| UV resistance | |

| Specification | DIN EN ISO 4892-2:2021-11 (following) |

| Result | Test passed |

| Test duration | 96 h |

| Procedure | Artificial irradiation. |

| Temperature storage | |

| Specification | IEC 60068-2-2:2007-07 |

| Result | Test passed |

| Procedure | Test Bb |

| Duration | 96 h |

| Temperature for testing | 105 °C |

| Temperature resistance | |

| Specification | ANSI/UL 969-2018:03 (following) |

| Test duration | 240 h |

| Rating 125 °C (150 °C) | Test passed |

| Wipe resistance of inscriptions | |

| Specification | DIN EN 61010-1 (VDE 0411-01):2020-03 |

| DIN EN 62208 (VDE 0660-511):2012-06 (in parts) | |

| Isopropanol (99%) [67-63-0] | Test passed |

| n-Hexane [CAS No. 110-54-3] |

Test passed |

| Water + Petroleum ether [CAS No. 64742-82-1] |

Test passed |

| Sodium hydroxide 0.1 mol/l [CAS No. 1310-73-2] |

Test passed |

| Ethanol (99 %) [CAS No. 64-17-5] |

Test passed |

| Immersion in chemicals, oil & fuel | |

| Specification | ISO 175:2010 (following) |

| Test duration | 168 h |

| Sodium hydroxide 0.1 mol/l [CAS No. 1310-73-2] |

Test passed |

| Saltwater (saturated 350 g/l) [CAS No. - ] |

Test passed |

| Ethanol (99 %) [CAS No. 64-17-5] |

Test passed |

| Diesel [CAS No. 68476-34-6] |

Test passed |

| IRM 901 | Test passed |

| IRM 902 | Test passed |

| IRM 903 | Test passed |

| Testing in a condensation changing climate in the presence of sulfur dioxide | |

| Specification | DIN EN ISO 22479:2022-08 |

| Result | Test passed |

| Procedure | Method B |

| Cycles | 2 |

| Salt spray test | |

| Specification | DIN EN IEC 60068-2-11 (VDE 0468-2-11):2022-10 |

| Result | Test passed |

| Test duration | 96 h |

| Mounting type | insert |

| N.º de artigo | 1352327 |

| Pcs./Emb | 1 Unidade |

| Quantidade mínima de pedido | 1 Unidade |

| Chave comercial | BG2 |

| Chave de produto | BG2211 |

| GTIN | 4063151674717 |

| Peso por unidade (inclusive embalagem) | 499,5 g |

| Peso por unidade (excluindo embalagem) | 490,8 g |

| Número do imposto alfandegário | 39191080 |

| País de origem | DE |

ECLASS

| ECLASS-13.0 | 27281106 |

| ECLASS-15.0 | 27281106 |

ETIM

| ETIM 10.0 | EC001288 |

UNSPSC

| UNSPSC 21.0 | 39131700 |

| EU RoHS | |

| Cumpre os requisitos de substância segundo a Diretiva RoHS | Sim (Sem regras de exceção) |

| EU REACH SVHC | |

| Nota sobre as substâncias candidatas ao REACH (n.º CAS) | Nenhuma substância numa proporção superior a 0,1 % em massa |

Produtos compatíveis

-

-

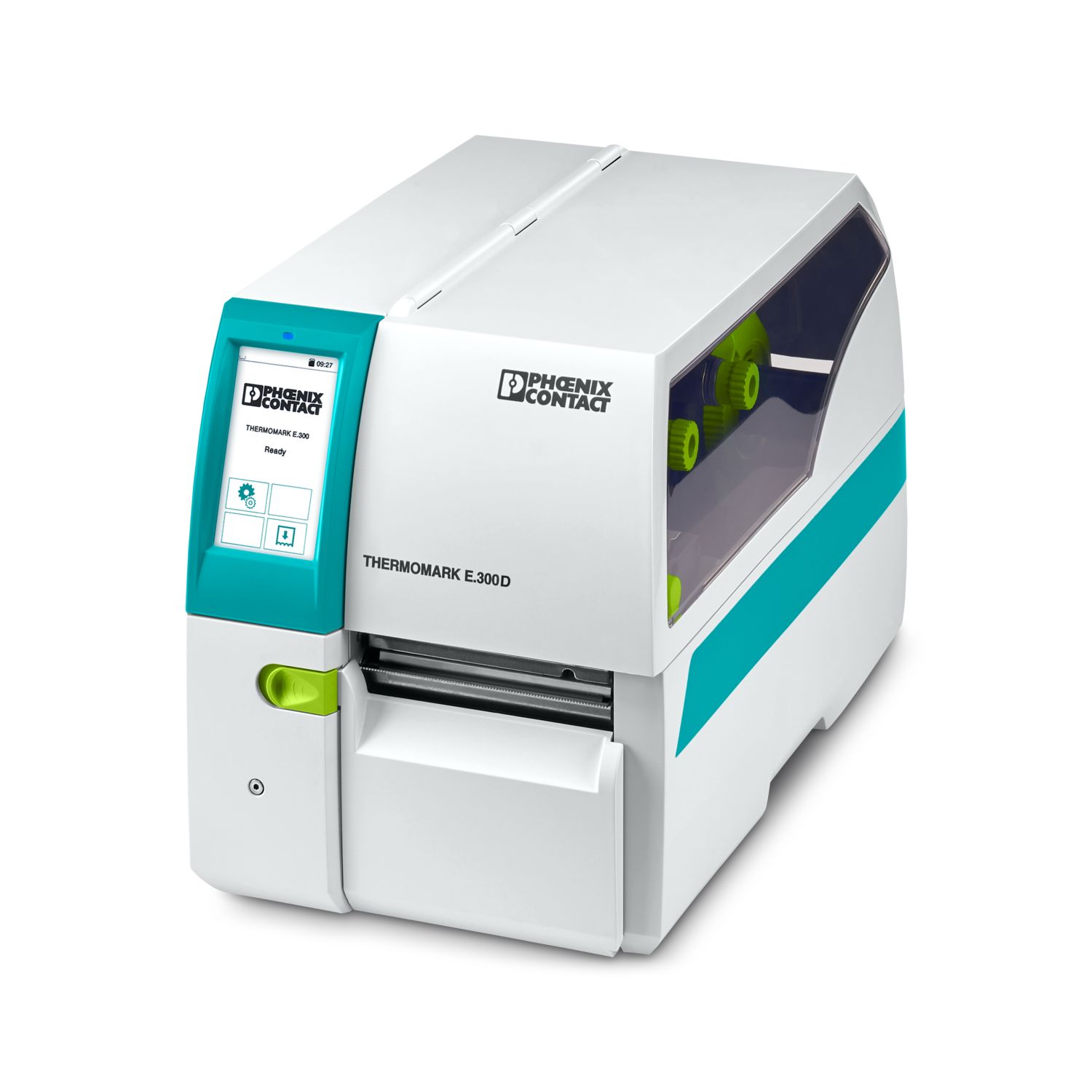

THERMOMARK E.300 D - Thermal transfer printer 1004303

-

THERMOMARK E.600 - Thermal transfer printer 1285310

-

THERMOMARK E.600 D - Thermal transfer printer 1004304

-

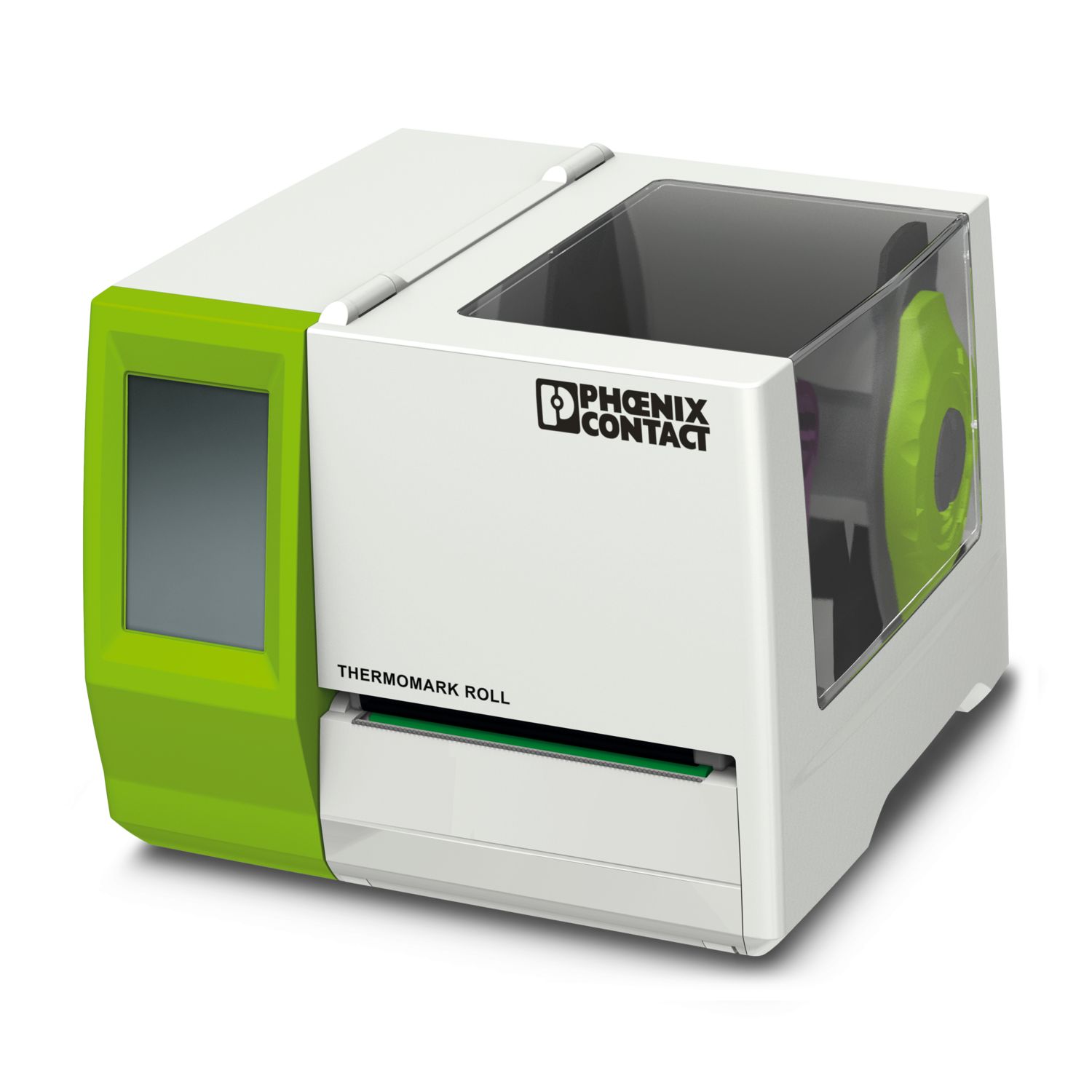

THERMOMARK ROLL 2.0 - Thermal transfer printer 1085260

-

THERMOMARK E.300 DOUBLE - Thermal transfer printer 1472379

-

THERMOMARK-RIBBON 110 - Ink ribbon 5145384

-

THERMOMARK-RIBBON 110/50 - Ink ribbon 0800687

-

PAB-KTL 23 - Cable marker carrier 1013957

-

PATG 0/23 - Conductor marker carrier 0828046

-

PATG 1/23 - Conductor marker carrier 1013847

-

PATG 2/23 - Conductor marker carrier 1013850

-

PATG 3/23 - Conductor marker carrier 1013863

-

PATG 4/23 - Conductor marker carrier 0808011

-

PATG 5/23 - Conductor marker carrier 0808024

-

PATG 6/23 - Conductor marker carrier 0808037

-

PATG 7/23 - Conductor marker carrier 0808040

-

PATG 8/23 - Conductor marker carrier 0808053

-

PATO 1/23 - Conductor marker carrier 1013892

-

PATO 2/23 - Conductor marker carrier 1013902

-

THERMOMARK ROLLMASTER 300 - Thermal transfer printer 0804501

-

THERMOMARK ROLLMASTER 600 - Thermal transfer printer 0804663

-

THERMOMARK ROLL - Thermal transfer printer 5146477

Vantagens

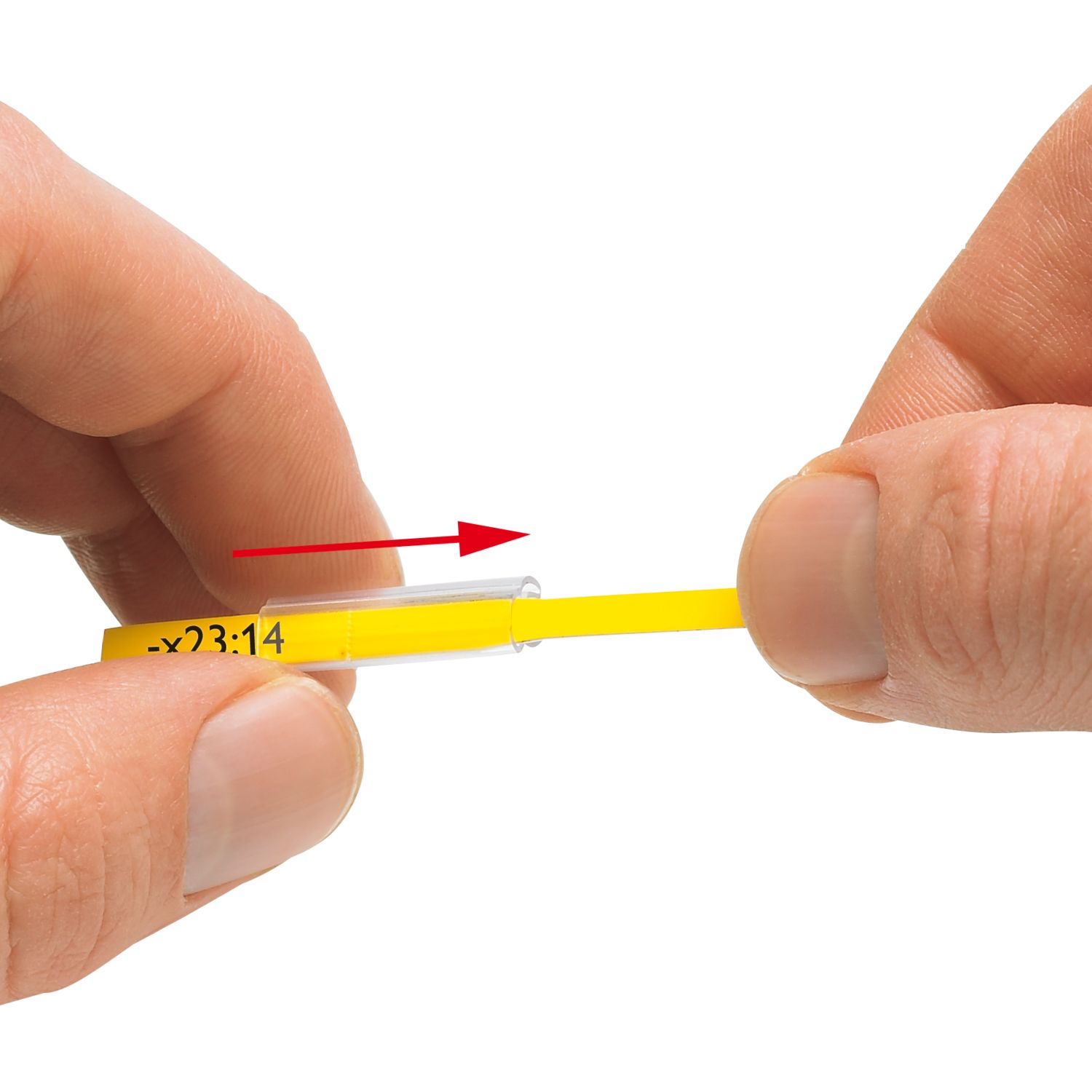

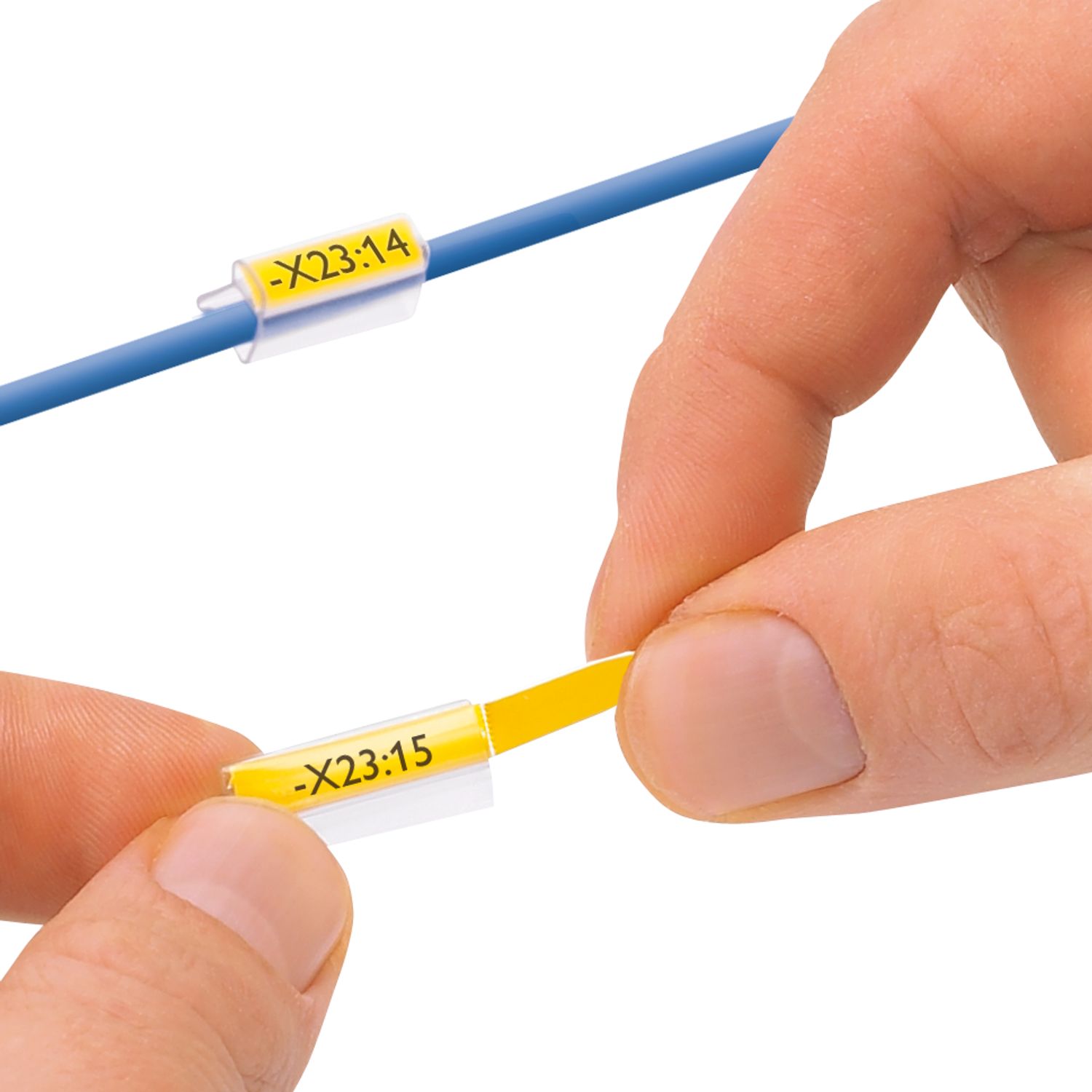

The WMTS ... range of marking material off the roll includes markers for wire marking with threading and insertion aid for the marking sleeves from the PATG/PATO ... system

Thanks to their special shape, the WMTS ... insert labels remain securely inside the sleeve once inserted

Quick and inexpensive marking with THERMOMARK ... roll printers from Phoenix Contact

When combined with the right ink ribbon, the marking is highly resistant to solvents and mechanical influences

Pesquisado com frequência

Phoenix Contact S.A.

Sintra Business Park, Edifício n°1 Zona Industrial da Abrunheira, sala 0M, 2710-089 SINTRA