EAC

ID de certificação: KZ7500651131219505UL Recognized

ID de certificação: FILE E 60425| Tensão nominal UN | Corrente nominal IN | Secção transversal American Wire Gauge | Secção transversal mm2 | |

|---|---|---|---|---|

| E | ||||

| 1000 V | 150 A | 6 - 1/0 | ||

| 1000 V | 120 A | 6 - 1/0 | ||

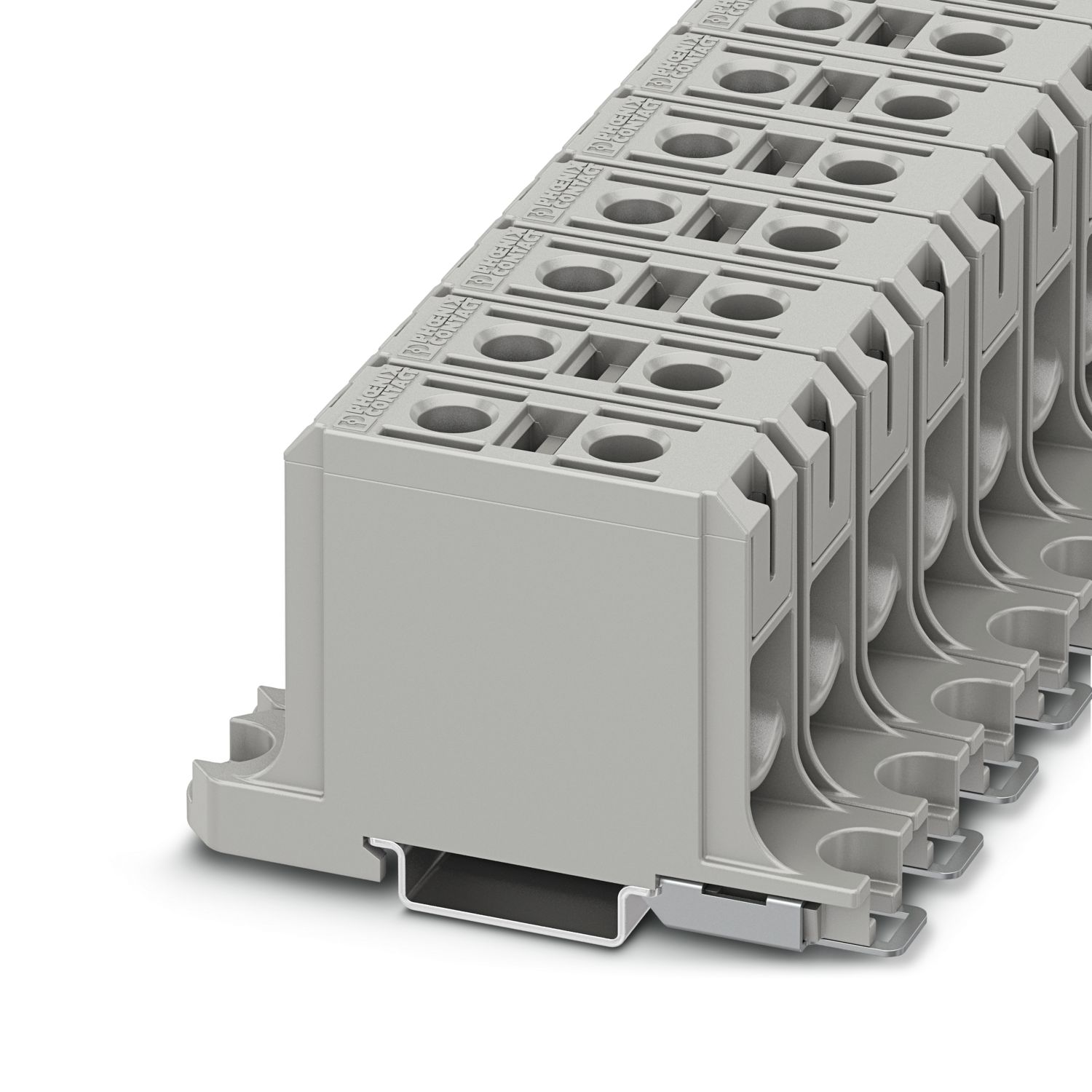

High-current terminal block, nom. voltage: 1000 V, nominal current: 145 A, number of connections: 2, number of positions: 1, connection method: Screw connection, Rated cross section: 50 mm2, cross section: 6 mm2 - 50 mm2, Rated cross section: 50 mm2, cross section: 4 mm2 - 50 mm2, mounting type: NS 35/15, NS 35/7,5, color: gray

| Tensão nominal UN | Corrente nominal IN | Secção transversal American Wire Gauge | Secção transversal mm2 | |

|---|---|---|---|---|

| E | ||||

| 1000 V | 150 A | 6 - 1/0 | ||

| 1000 V | 120 A | 6 - 1/0 | ||