EAC

ID de certificação: KZ7500651131219505cULus Recognized

ID de certificação: E60425| Tensão nominal UN | Corrente nominal IN | Secção transversal American Wire Gauge | Secção transversal mm2 | |

|---|---|---|---|---|

| B | ||||

| 600 V | 150 A | 6 - 1/0 | ||

| C | ||||

| 600 V | 150 A | 6 - 1/0 | ||

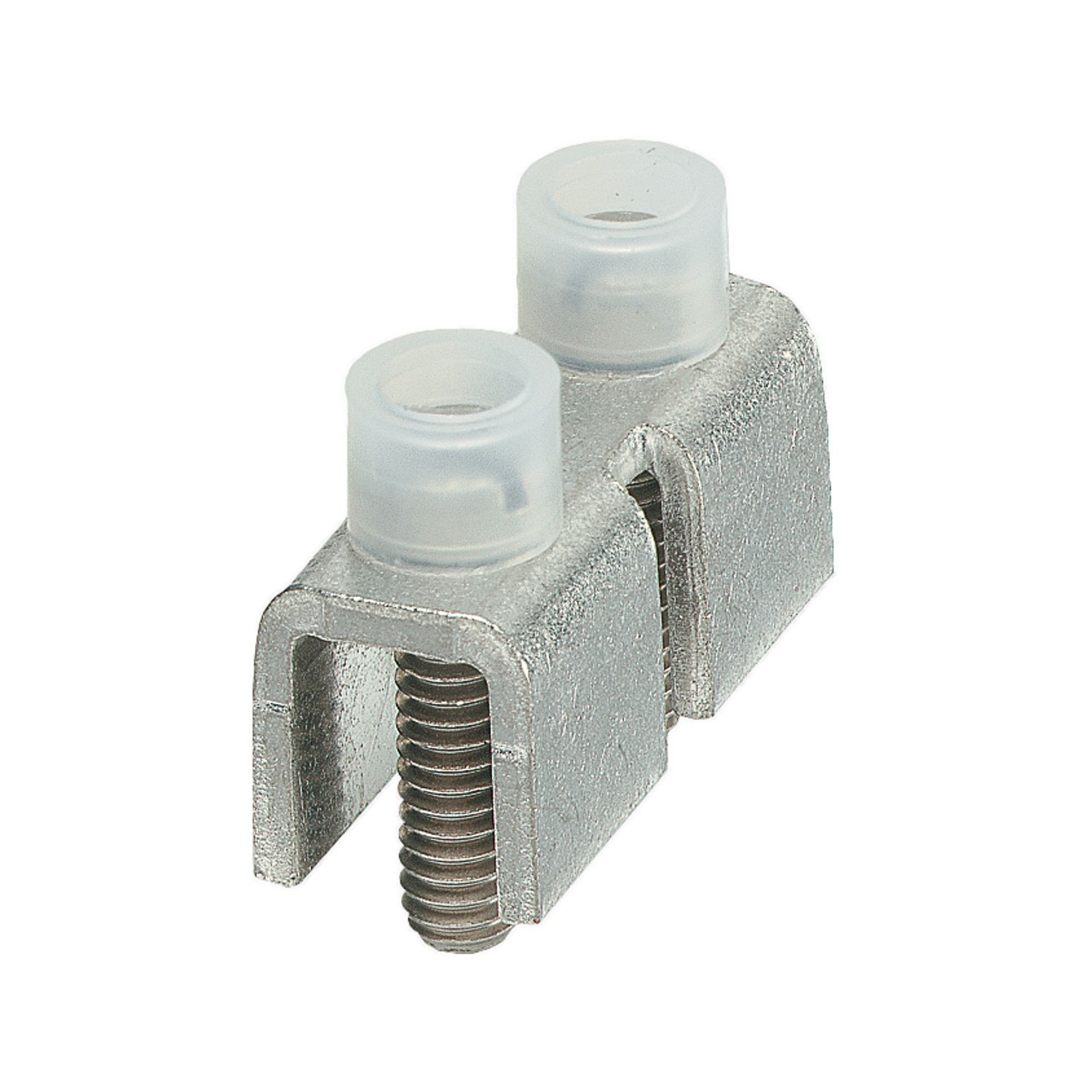

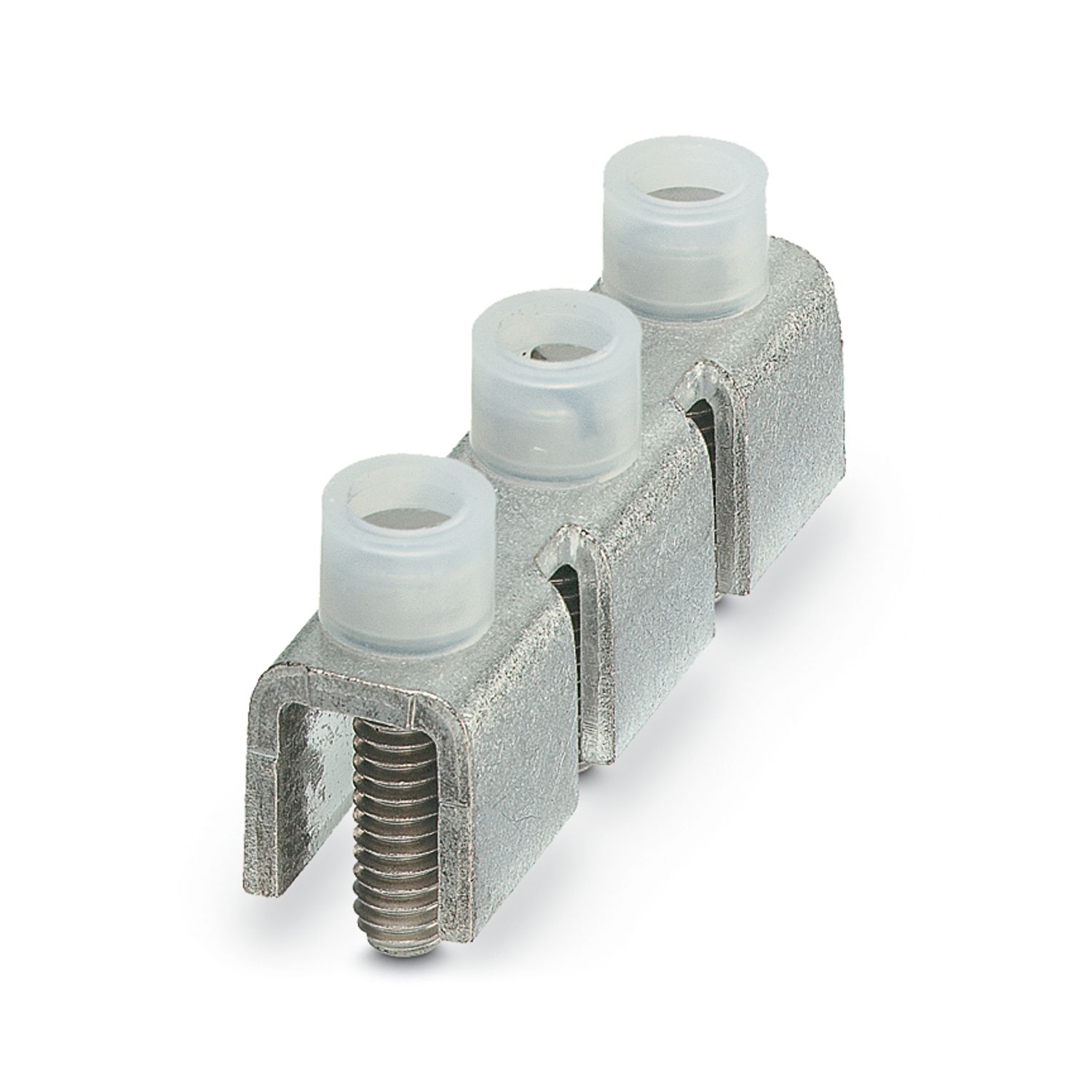

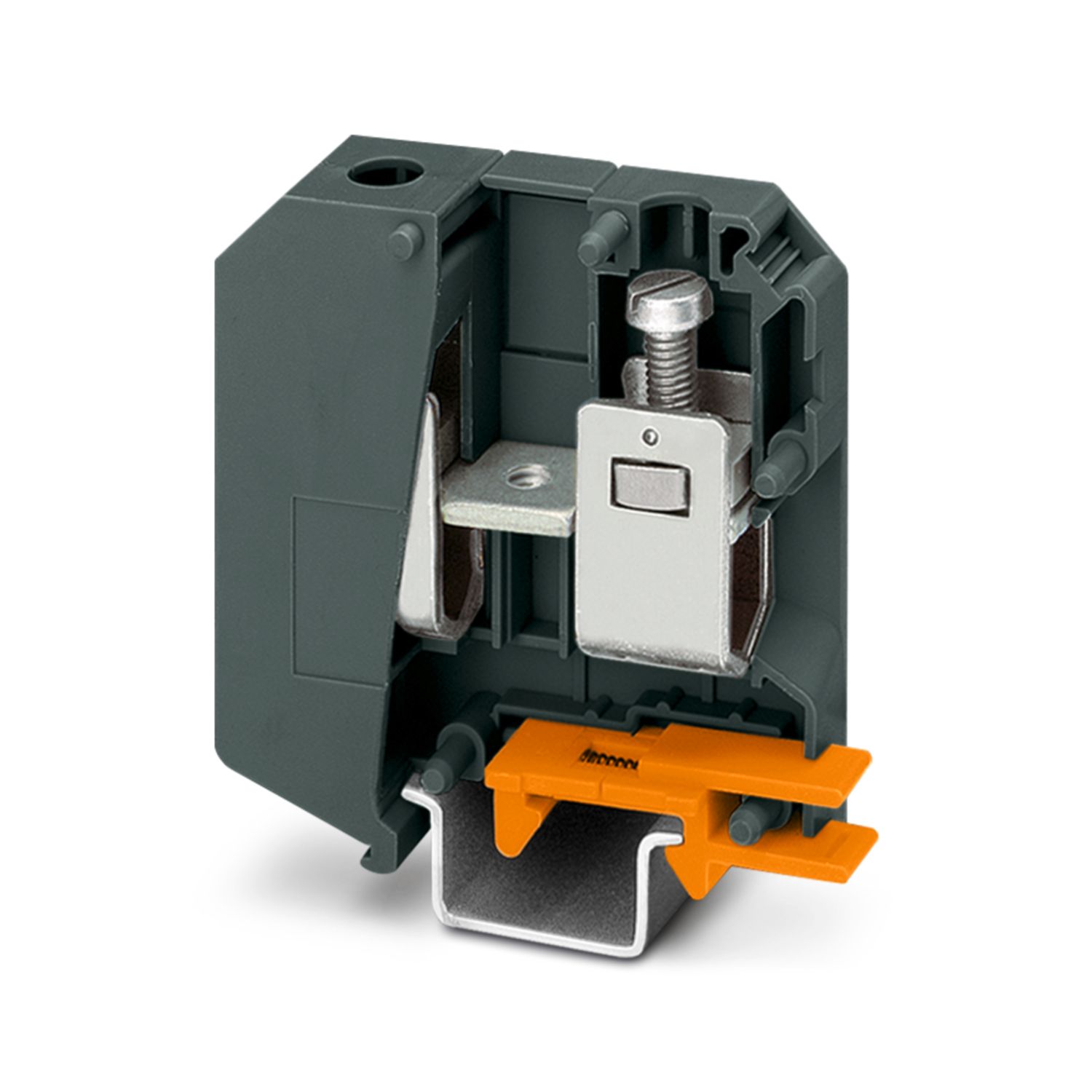

Feed-through terminal block, nom. voltage: 1000 V, nominal current: 150 A, number of connections: 2, number of positions: 1, connection method: Screw connection, Rated cross section: 50 mm2, cross section: 16 mm2 - 70 mm2, mounting type: NS 35/7,5, NS 35/15, color: dark gray

| Product family | TB |

| Number of positions | 1 |

| Number of connections | 2 |

| Number of rows | 1 |

| Insulation characteristics | |

| Overvoltage category | III |

| Degree of pollution | 3 |

| Maximum power dissipation for nominal condition | 4.73 W |

| Number of connections per level | 2 |

| Nominal cross section | 50 mm² |

| Rated cross section AWG | 1/0 |

| Connection method | Screw connection |

| Screw thread | M6 |

| Tightening torque | 6 ... 8 Nm |

| Stripping length | 24 mm |

| Internal cylindrical gage | A10 |

| B10 | |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 16 mm² ... 70 mm² |

| Cross section AWG | 4 ... 2/0 (converted acc. to IEC) |

| Conductor cross-section flexible | 25 mm² ... 70 mm² |

| Conductor cross-section, flexible [AWG] | 2 ... 2/0 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 25 mm² ... 50 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 25 mm² ... 50 mm² |

| 2 conductors with same cross section, solid | 10 mm² ... 16 mm² |

| 2 conductors with the same cross-section AWG rigid | 6 ... 4 (converted acc. to IEC) |

| 2 conductors with same cross section, flexible | 10 mm² ... 16 mm² |

| 2 conductors with the same cross-section AWG flexible | 6 ... 4 (converted acc. to IEC) |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 10 mm² ... 16 mm² |

| Nominal current | 150 A |

| Maximum load current | 150 A |

| Nominal voltage | 1000 V |

| Nominal cross section | 50 mm² |

| Width | 20 mm |

| Height | 70.5 mm |

| Depth on NS 32 | 81.5 mm |

| Depth on NS 35/15 | 83.5 mm |

| Color | traffic grey B (RAL 7043) |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Surge voltage test | |

| Test voltage setpoint | 9.8 kV |

| Result | Test passed |

| Temperature-rise test | |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 50 mm² | 6 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 2.2 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | No |

| Mechanical strength | |

| Result | Test passed |

| Attachment on the carrier | |

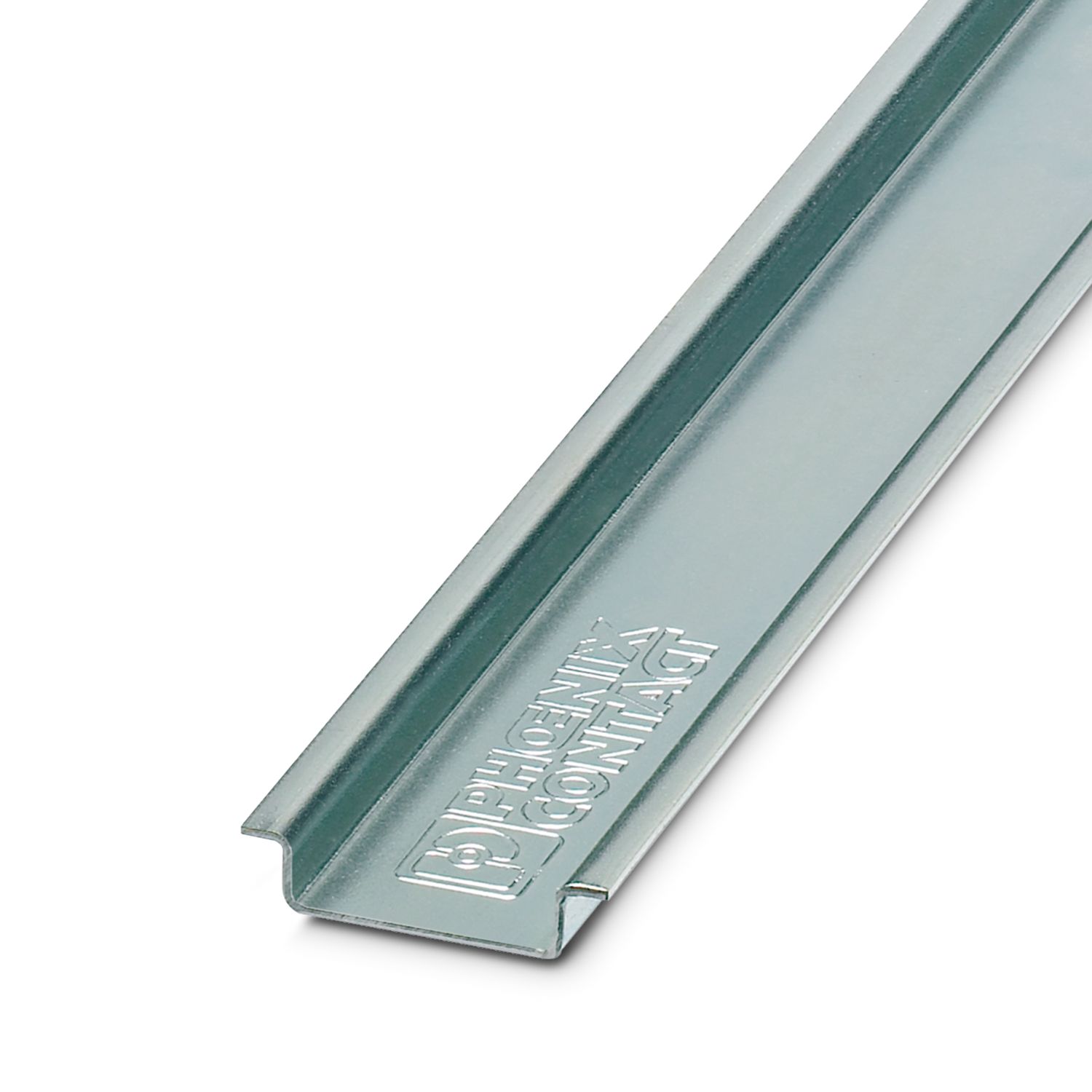

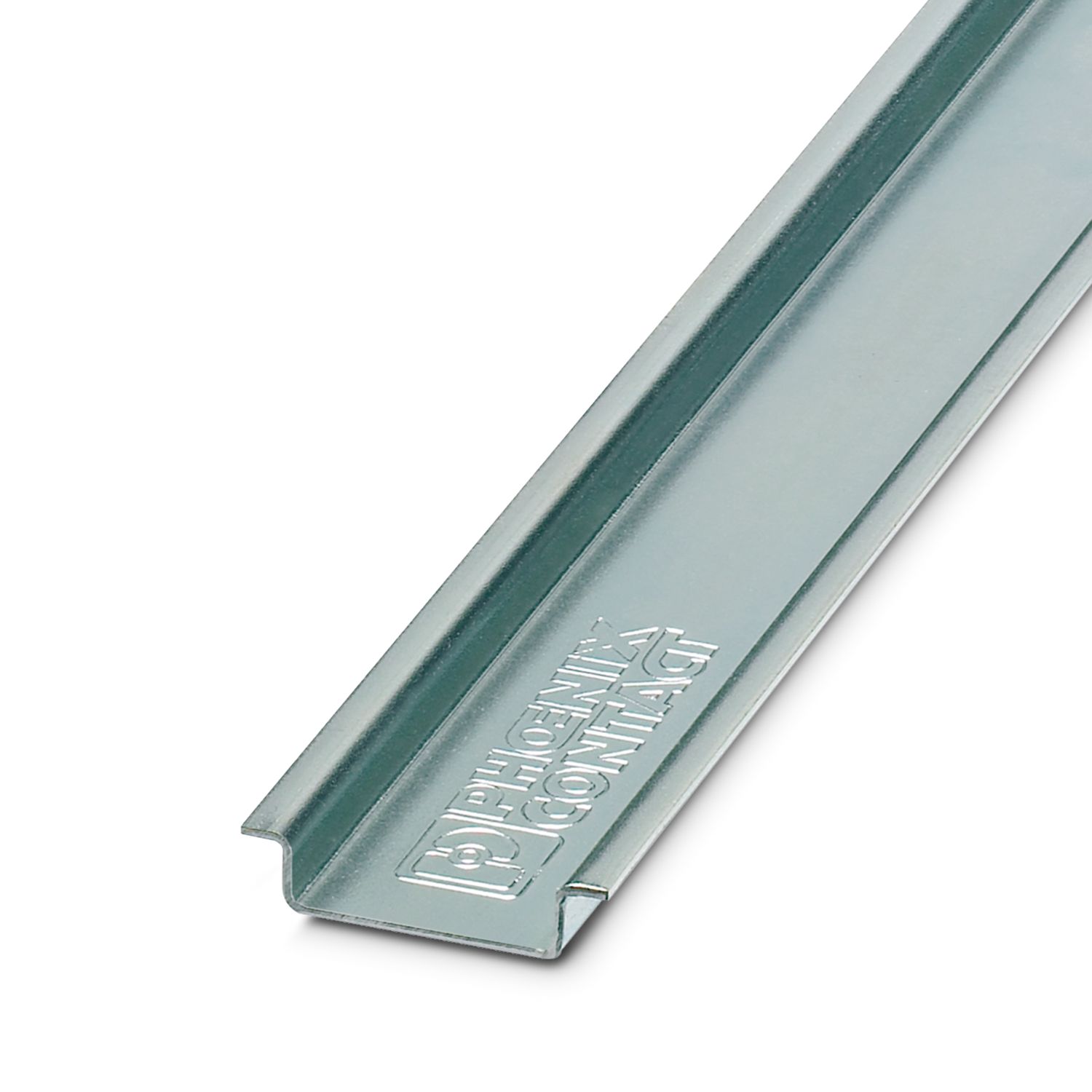

| DIN rail/fixing support | NS 32/NS 35 |

| Test force setpoint | 10 N |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Rotation speed | 10 (+/- 2) rpm |

| Revolutions | 135 |

| Conductor cross-section/weight | 16 mm² / 2.9 kg |

| 50 mm² / 9.5 kg | |

| 70 mm²/10.4 kg | |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 30 s |

| Result | Test passed |

| Oscillation/broadband noise | |

| Specification | DIN EN 50155 (VDE 0115-200):2022-06 |

| Spectrum | Long life test category 2, bogie-mounted |

| Frequency | f1 = 5 Hz to f2 = 250 Hz |

| ASD level | 6.12 (m/s²)²/Hz |

| Acceleration | 3.12g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

| Shocks | |

| Pulse shape | Half-sine |

| Acceleration | 5g |

| Shock duration | 30 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

| Ambient conditions | |

| Ambient temperature (operation) | -60 °C ... 110 °C (Operating temperature range incl. self-heating; for max. short-term operating temperature, see RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (operation) | 20 % ... 90 % |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 60947-7-1 |

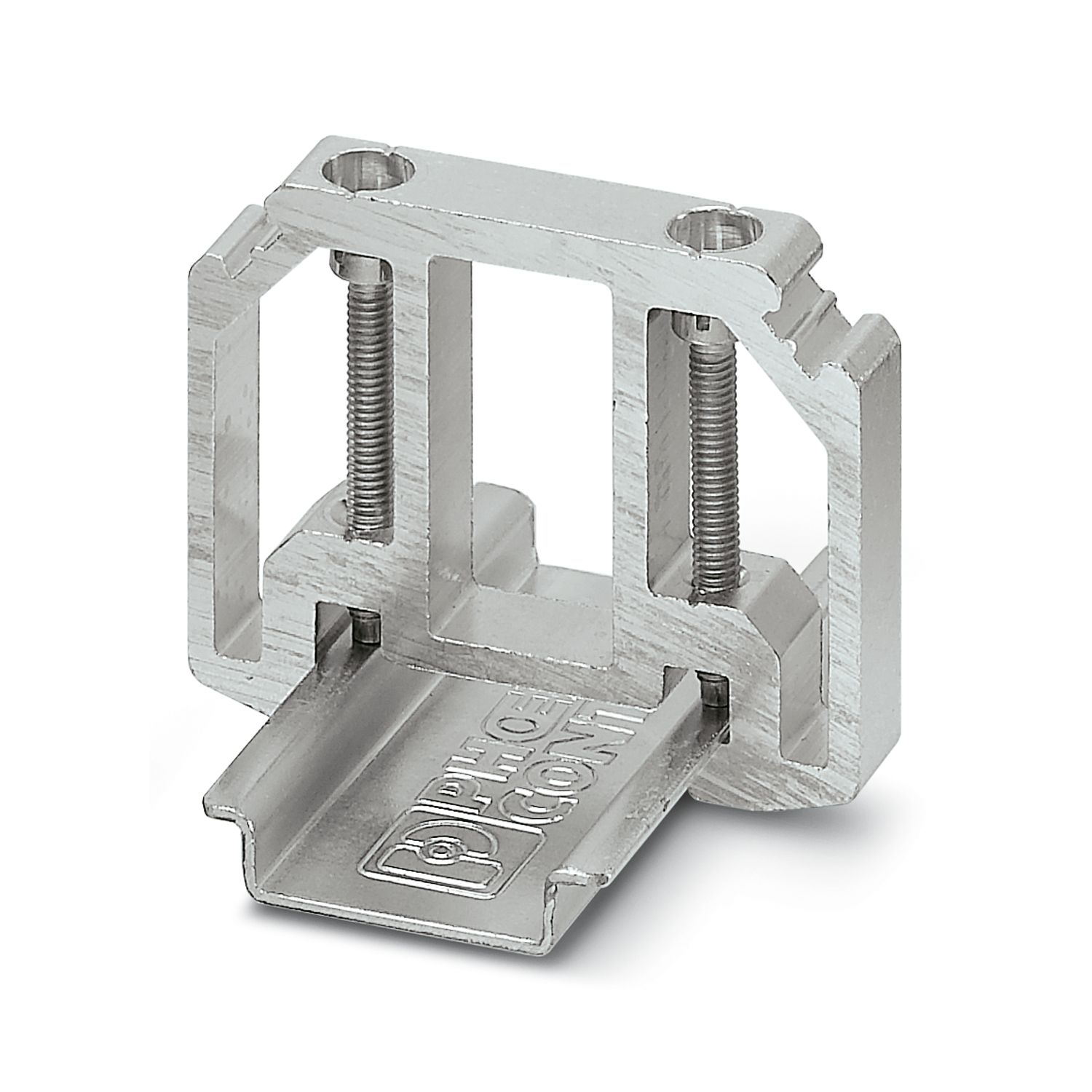

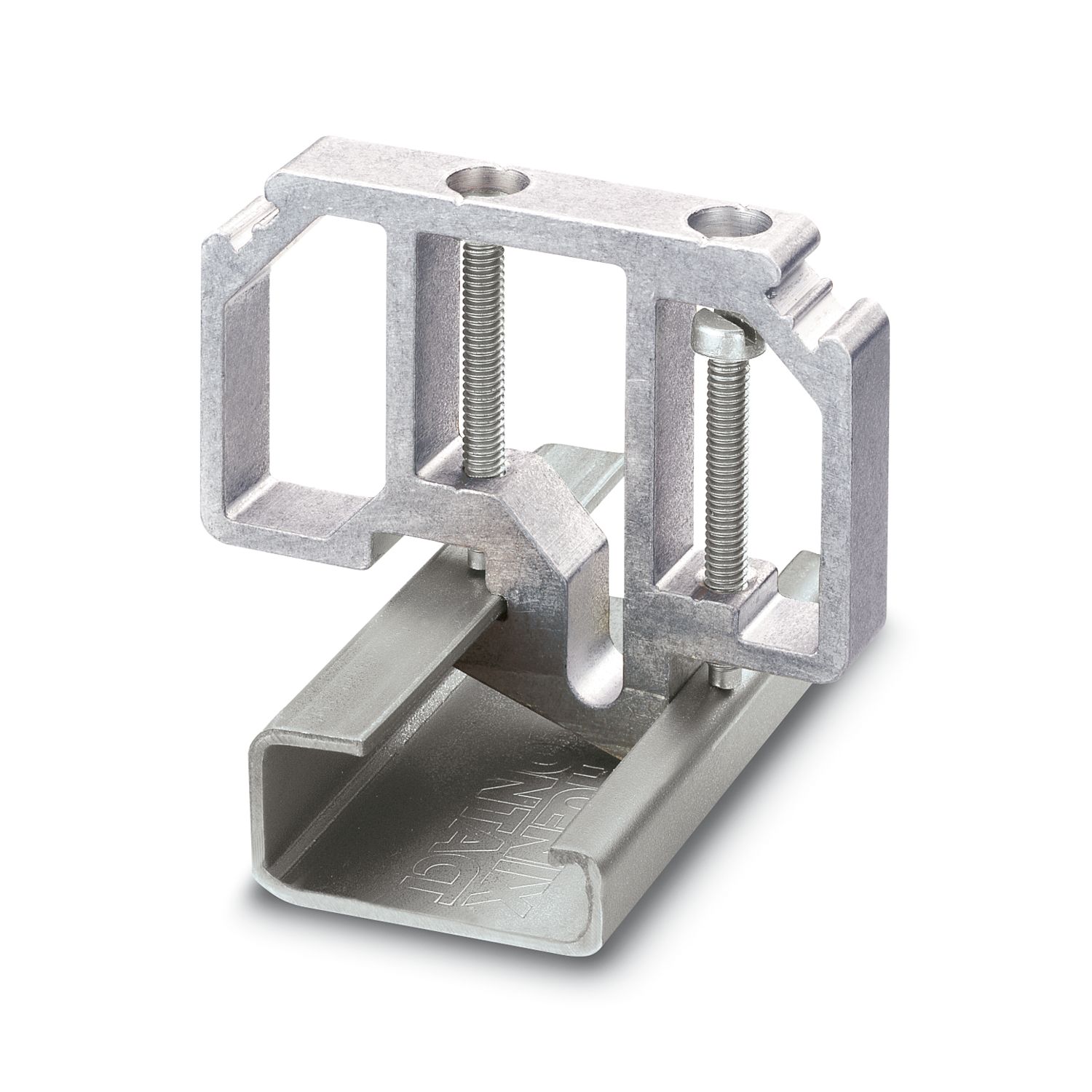

| Mounting type | NS 35/7,5 |

| NS 35/15 |

| N.º de artigo | 3247180 |

| Pcs./Emb | 10 Unidade |

| Quantidade mínima de pedido | 10 Unidade |

| Chave comercial | BEK |

| Chave de produto | BEK311 |

| GTIN | 4046356723558 |

| Peso por unidade (inclusive embalagem) | 121,85 g |

| Peso por unidade (excluindo embalagem) | 121,07 g |

| Número do imposto alfandegário | 85369010 |

| País de origem | IN |

| ECLASS-13.0 | 27250101 |

| ECLASS-15.0 | 27250101 |

| ETIM 9.0 | EC000897 |

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Cumpre os requisitos de substância segundo a Diretiva RoHS | Sim (Sem regras de exceção) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

Nenhuma substância perigosa acima dos valores-limite

|

| EU REACH SVHC | |

| Nota sobre as substâncias candidatas ao REACH (n.º CAS) | Nenhuma substância numa proporção superior a 0,1 % em massa |