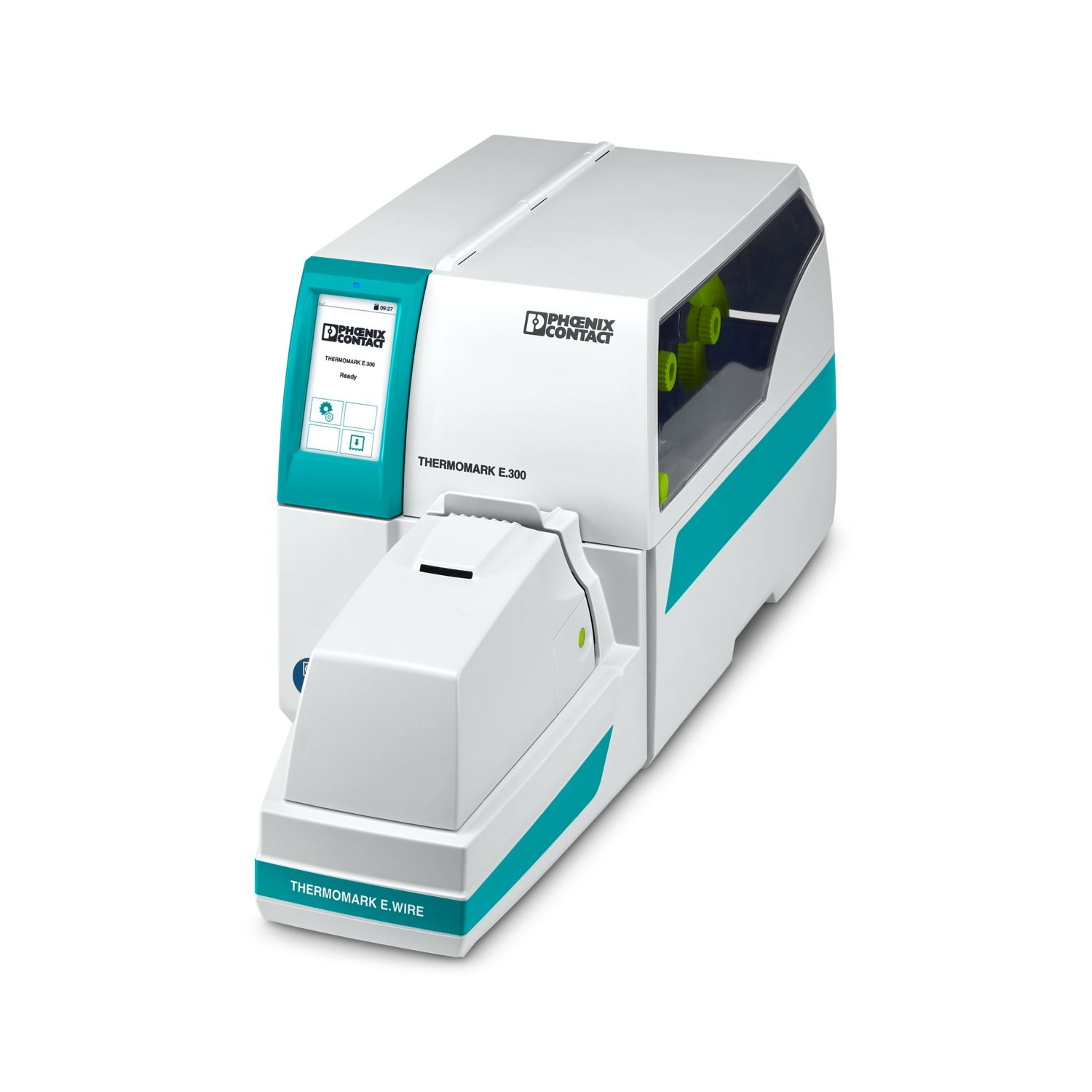

THERMOMARK E.WIRE套件可显著提高导线和电缆标识的生产效率。在导线和电缆标识过程中,为实现高效率,可将THERMOMARK E.300卷式打印机与THERMOMARK E.WIRE标识打印安装设备组合使用。这就为您提供了一套自动化打印和标识安装系统,与手动标识过程相比,可节省高达70%的用时。

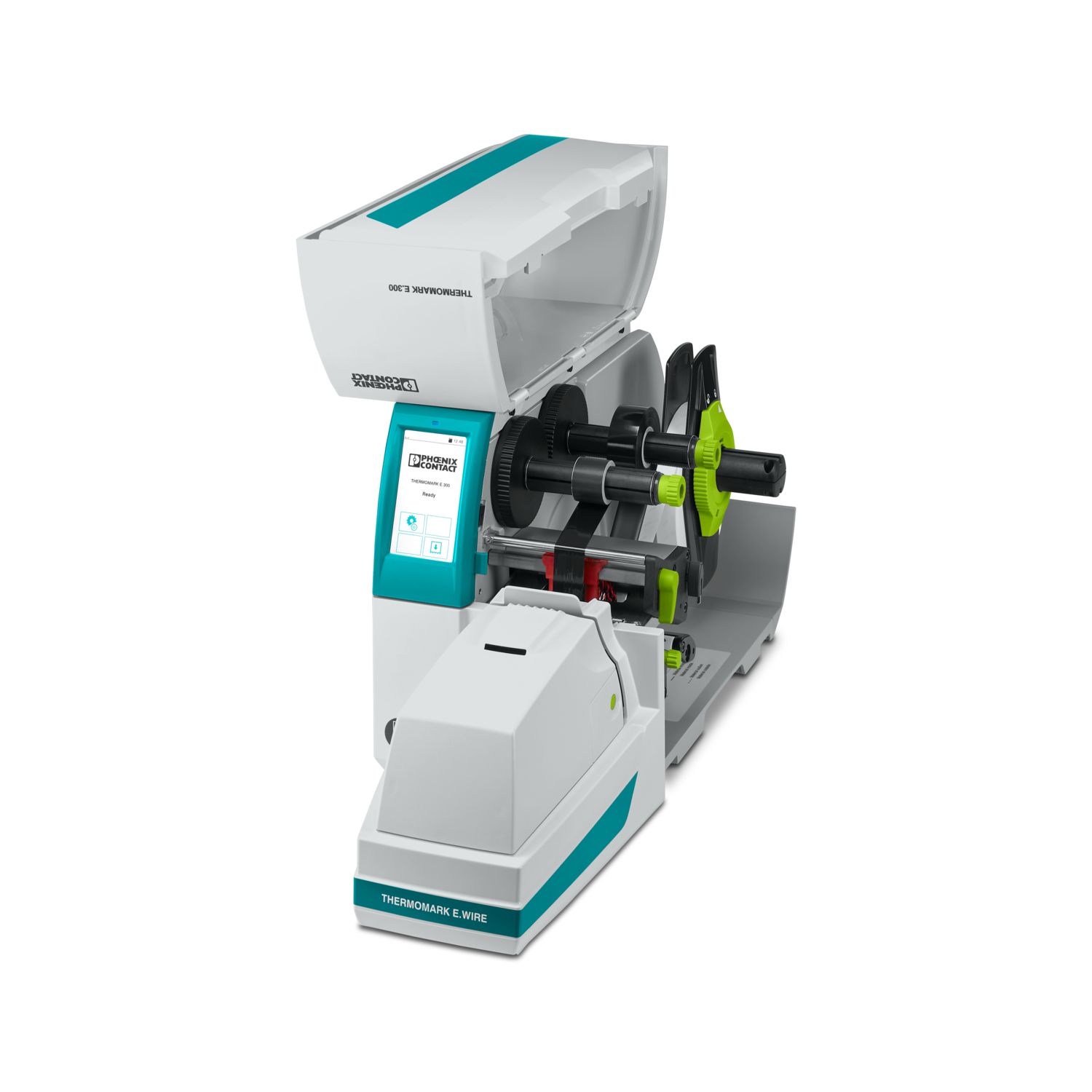

可移动型标识适用于所有类型的圆柱形物体和双绞线。由于标识形状为三角形,因此可在所有三个侧面上进行标识。在此过程中,THERMOMARK E.WIRE会自动测量圆柱形物体的直径,将由THERMOMARK E.300 BASIC打印的E-WM...连续型标识膜卷材切割至所需长度,然后将其卷绕在圆柱形物体上,随即用热封接头密封标识。这样就打造出与直径高度适配的专属标识,并还可在径向和轴向上移动。得益于这一独特系统,直径在1.8 mm/0.07"到5.6 mm/0.22"之间的各类物体均可使用同一型号的材料进行高效标识。

供货范围:

THERMOMARK E.WIRE (1203216)、TM E.WIRE/E.SLEEVE-PR压力滚轴 (1259203)、THERMOMARK E.300 BASIC、电源电缆(针式连接器样式:F型)、USB电缆和多语言装箱单。

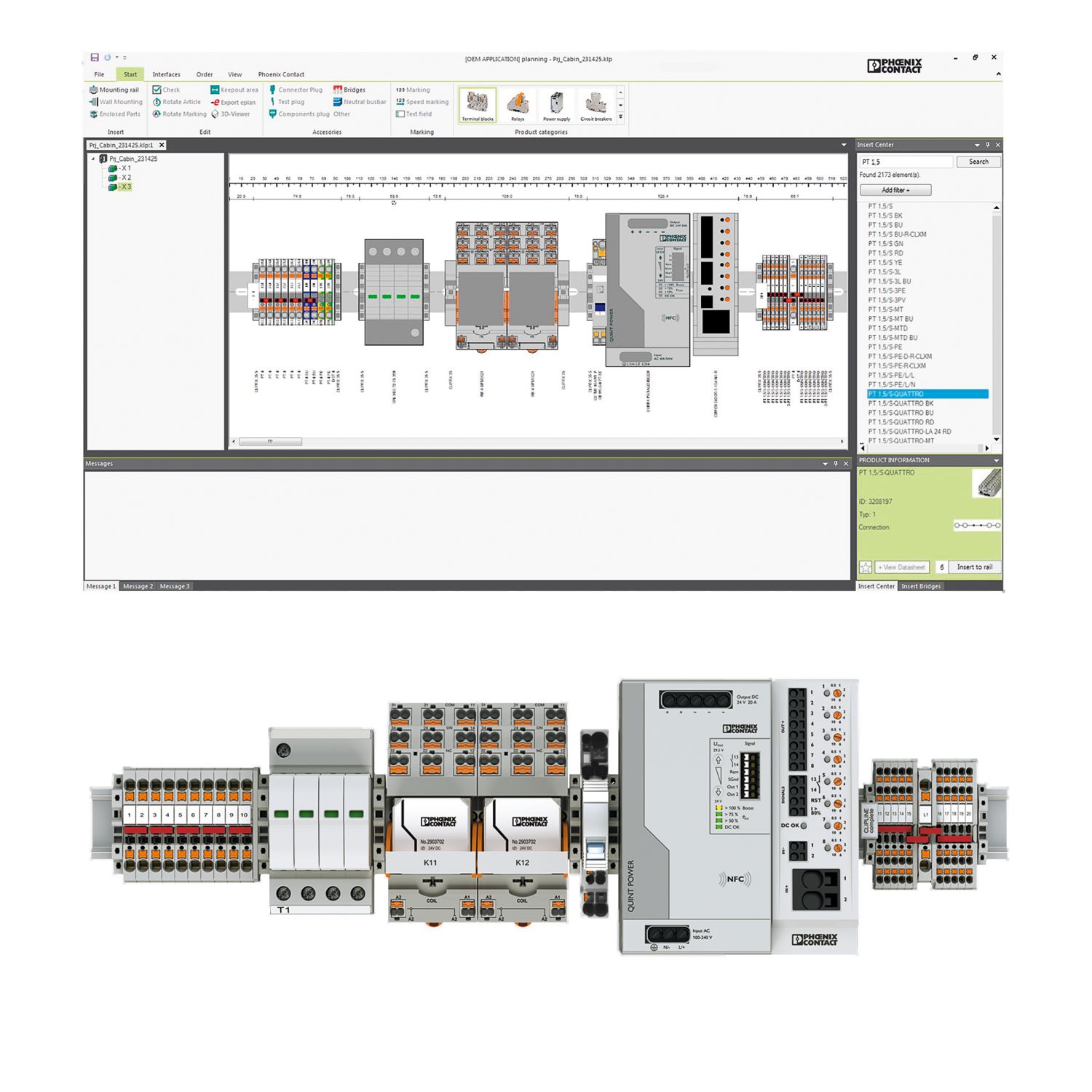

注意:

THERMOMARK E.300 (D) BASIC打印系统搭配相应的标识打印安装设备即可立即投入使用。产品与THERMOMARK E.300 (D)/E.600 (D) 标准打印机的区别在于其供货范围较小。不包括TM E.300/E.600-FRONT COVER前盖板 (1285305)、TM E.300/E.600-TEAR OFF PLATE拆板 (1263118)、TRM-PRESSURE ROLLER STANDARD标准压力滚轴 (0804655)、EML (20X8)R/TL标签卷材 (0802999) 和THERMOMARK-RIBBON 110/50色带 (0800687)。