WML 6 (13X13)RL

-

Wire-wrap label

0830677

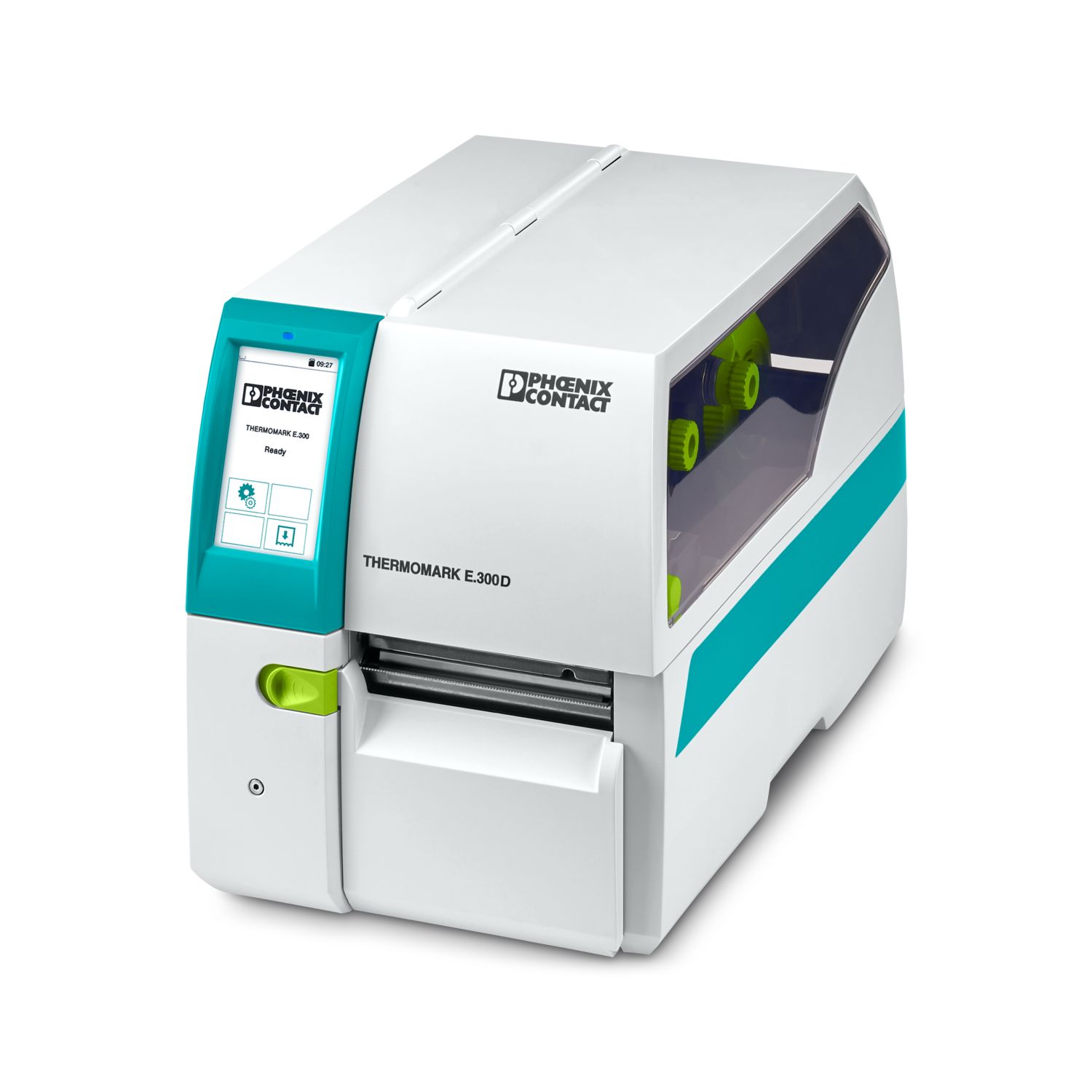

Wire-wrap label, Roll, white, unmarked, can be labeled with: THERMOMARK E.300 (D)/600 (D), THERMOMARK ROLL 2.0, THERMOMARK ROLL, THERMOMARK ROLL X1, THERMOMARK ROLLMASTER 300/600, THERMOMARK X1.2, cable diameter range: 4 ... 6.1 mm, mounting type: adhesive, cable diameter: ≤ 6.1 mm, Number of individual labels: 15000, text field height: 12.7 mm, text field width: 12.7 mm

Detalhes dos produtos

Produtos compatíveis

Vantagens

For indoor and outdoor applications: high resistance to dirt and abrasion due to the protective laminate

Firmly defined positioning of labels thanks to the adhesive system

Broad diameter range with many different applications inside and outside the control cabinet

The wrap-around labels do not create any additional volume, so the cable can also be pulled through cable ducts, for example

Quick and easy handling

For cylindrical objects, single wires, and cables