LS-EMLP (180X180) WH

-

Device marker

0804346

Device marker, Sheet, white, unmarked, can be labeled with: TOPMARK NEO, TOPMARK LASER, mounting type: adhesive, Number of individual labels: 1, text field height: 180 mm, text field width: 180 mm

Detalhes dos produtos

Produtos compatíveis

Vantagens

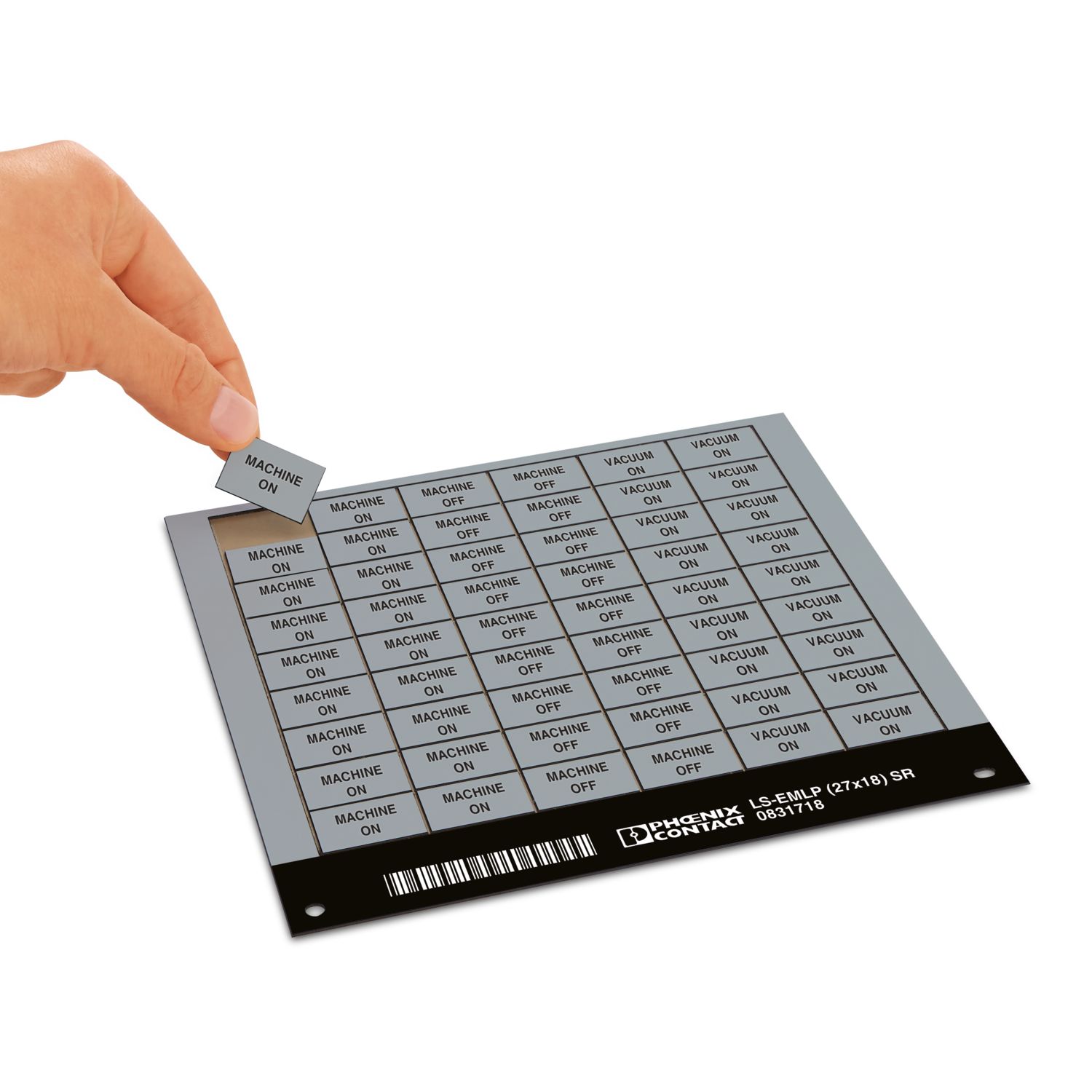

Stick-on device marking

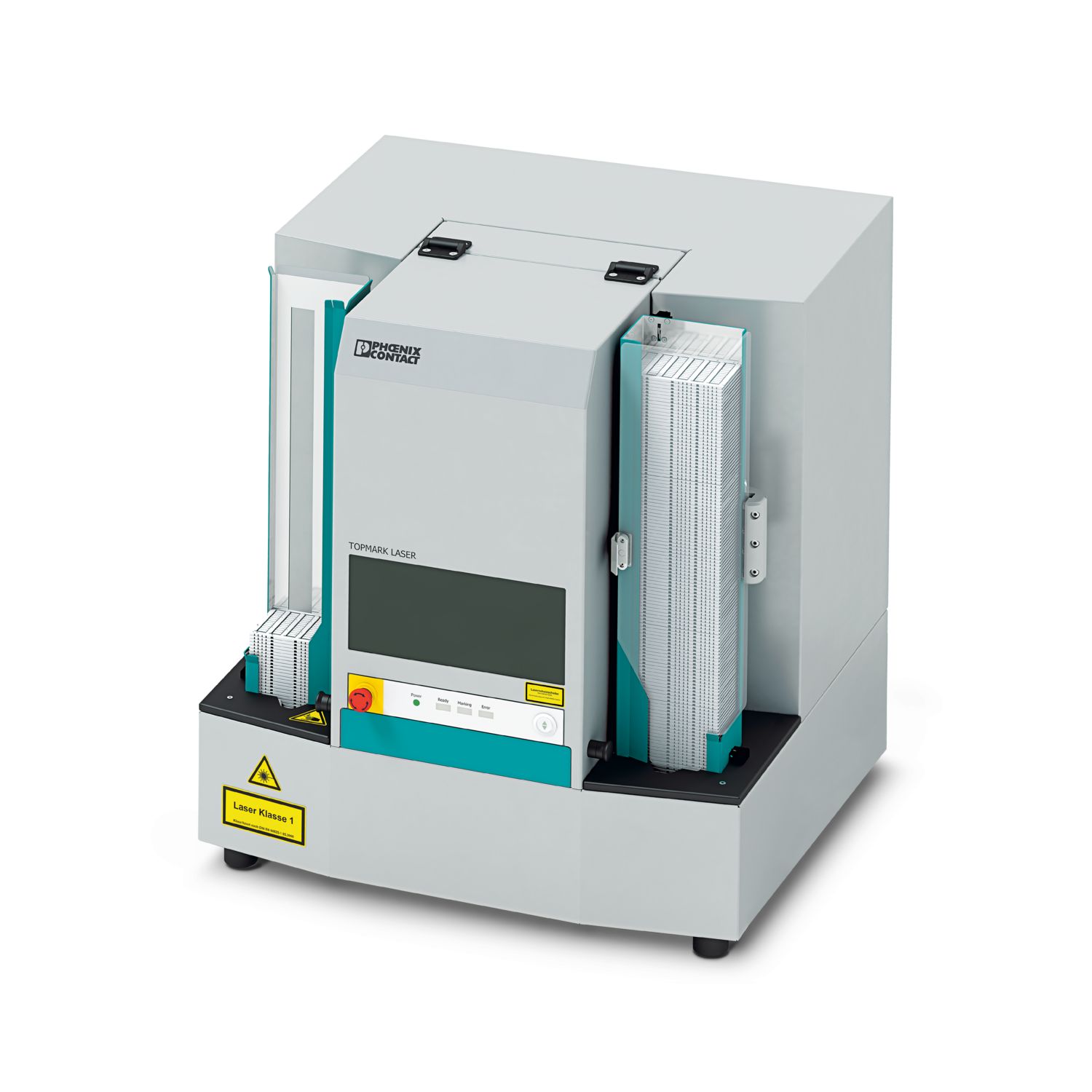

Individually configurable equipment marking in proven laser sheet format for optimum positioning in the marking device

Very high contrast due to the white top layer with black marking