EML-RM (15X15)RL-T

-

Label, can be removed

0830542

Label, can be removed, Roll, white, unmarked, can be labeled with: THERMOMARK E.300 (D)/600 (D), THERMOMARK ROLL 2.0, THERMOMARK ROLL, THERMOMARK ROLL X1, THERMOMARK ROLLMASTER 300/600, THERMOMARK X1.2, mounting type: adhesive, Number of individual labels: 8000, text field height: 15 mm, text field width: 15 mm

Detalhes dos produtos

| General | For the THERMOMARK ROLL and THERMOMARK ROLL 2.0 roll printers, this material can only be processed with an external media hub. |

| Product property | removable |

| Marking | |

| Number of individual labels | 8000 |

| Number of individual labels per row | 1 |

| Identification technology | Thermotransfer |

| Width | 15 mm |

| Length | 15 mm |

| Text field | |

| Text field width | 15 mm |

| Text field height | 15 mm |

| Color | white (RAL 9010) |

| Material | Polyester |

| Base element material | Polyester |

| Components | free from silicone and halogen |

| Test for substances that would hinder coating with paint or varnish | |

| Testing for paint wetting impairment substances (LABS-conformity) | VW PV 3.10.7:2005-02 |

| Result | Test passed |

| Test for substances that would hinder coating with paint or varnish | |

| Testing for paint wetting impairment substances (LABS-conformity) | VDMA 24364:2018-05 |

| Result | Test passed |

| Scratch resistance | |

| Specification | DIN EN ISO 1518-1:2019-10 (following) |

| Requirements | ≥ 5 N |

| Result | Test passed |

| Tesafilm test | |

| Specification | DIN EN ISO 2409:2013 (following) |

| Result | Test passed |

| UV resistance | |

| Specification | ISO 4892-2:2013-03 (following) |

| Result | Test passed |

| Test duration | 96 h |

| Procedure | Artificial irradiation. |

| Temperature resistance | |

| Specification | ANSI/UL 969-2018:03 (following) |

| Test duration | 240 h |

| Rating 150 °C (180 °C) | Test passed |

| Wipe resistance of inscriptions | |

| Specification | DIN EN 61010-1 (VDE 0411-01):2020-03 |

| DIN EN 62208 (VDE 0660-511):2012-06 (in parts) | |

| Isopropanol (99%) [67-63-0] | Test passed |

| n-Hexane [CAS No. 110-54-3] |

Test passed |

| Water + Petroleum ether [CAS No. 64742-82-1] |

Test passed |

| Sodium hydroxide 0.1 mol/l [CAS No. 1310-73-2] |

Test passed |

| Ethanol (99 %) [CAS No. 64-17-5] |

Test passed |

| Immersion in chemicals, oil & fuel | |

| Specification | ISO 175:2010 (following) |

| Test duration | 168 h |

| Saltwater (saturated 350 g/l) [CAS No. - ] |

Test passed |

| Ethanol (99 %) [CAS No. 64-17-5] |

Test passed |

| Diesel [CAS No. 68476-34-6] |

Test passed |

| IRM 901 | Test passed |

| IRM 902 | Test passed |

| IRM 903 | Test passed |

| Testing in a condensation changing climate in the presence of sulfur dioxide | |

| Specification | DIN 50018:2013-05 |

| Result | Test passed |

| Climate level | AHT 1.0 S |

| Cycles | 2 |

| Salt spray test | |

| Specification | DIN EN 60068-2-11:2000-02 |

| Result | Test passed |

| Test duration | 96 h |

| Ambient conditions | |

| Ambient temperature (operation) | -40 °C ... 120 °C |

| Ambient temperature (assembly) | > 15 °C |

| Recommended ambient temperature (storage/transport) | 23 °C |

| Recommended humidity (storage/transport) | 50 % (Storage in a dry and dark place in the original packaging is recommended) |

| Shelf life | 2 years |

| Wipe resistance | DIN EN 61010-1 (VDE 0411-1) |

| Mounting type | adhesive |

| N.º de artigo | 0830542 |

| Pcs./Emb | 1 Unidade |

| Quantidade mínima de pedido | 1 Unidade |

| Chave comercial | BG2 |

| Chave de produto | BG2411 |

| GTIN | 4046356720540 |

| Peso por unidade (inclusive embalagem) | 520,8 g |

| Peso por unidade (excluindo embalagem) | 520,8 g |

| Número do imposto alfandegário | 39269097 |

| País de origem | DE |

ECLASS

| ECLASS-13.0 | 27281103 |

ETIM

| ETIM 9.0 | EC001288 |

UNSPSC

| UNSPSC 21.0 | 39131500 |

| EU RoHS | |

| Cumpre os requisitos de substância segundo a Diretiva RoHS | Sim (Sem regras de exceção) |

| EU REACH SVHC | |

| Nota sobre as substâncias candidatas ao REACH (n.º CAS) | Nenhuma substância numa proporção superior a 0,1 % em massa |

Produtos compatíveis

-

-

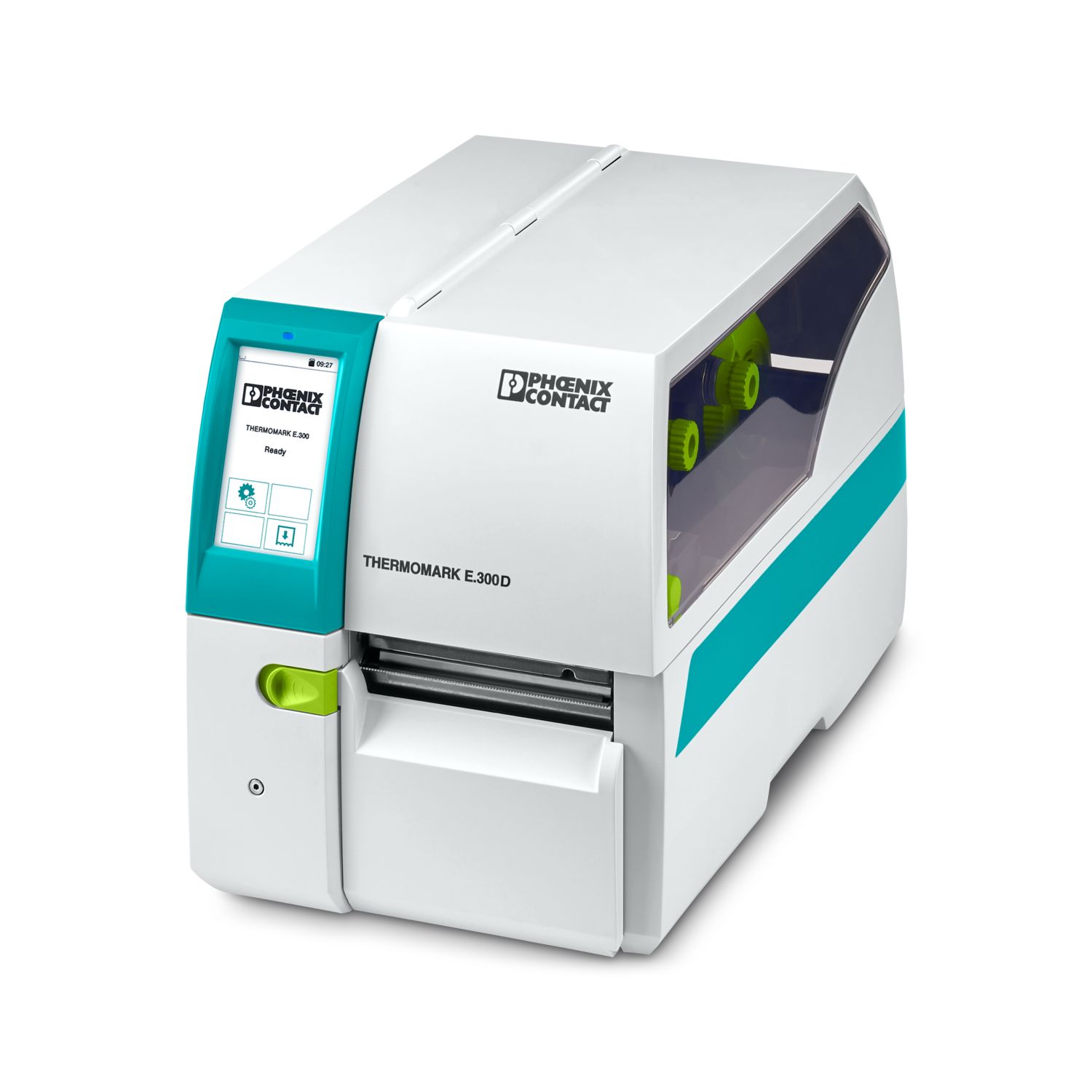

THERMOMARK E.300 D - Thermal transfer printer 1004303

-

THERMOMARK E.600 - Thermal transfer printer 1285310

-

THERMOMARK E.600 D - Thermal transfer printer 1004304

-

THERMOMARK ROLL 2.0 - Thermal transfer printer 1085260

-

THERMOMARK-RIBBON 110 - Ink ribbon 5145384

-

THERMOMARK-RIBBON 110/50 - Ink ribbon 0800687

-

THERMOMARK ROLL-ERH - Media hub 5146448

-

THERMOMARK ROLLMASTER 300 - Thermal transfer printer 0804501

-

THERMOMARK ROLLMASTER 600 - Thermal transfer printer 0804663

-

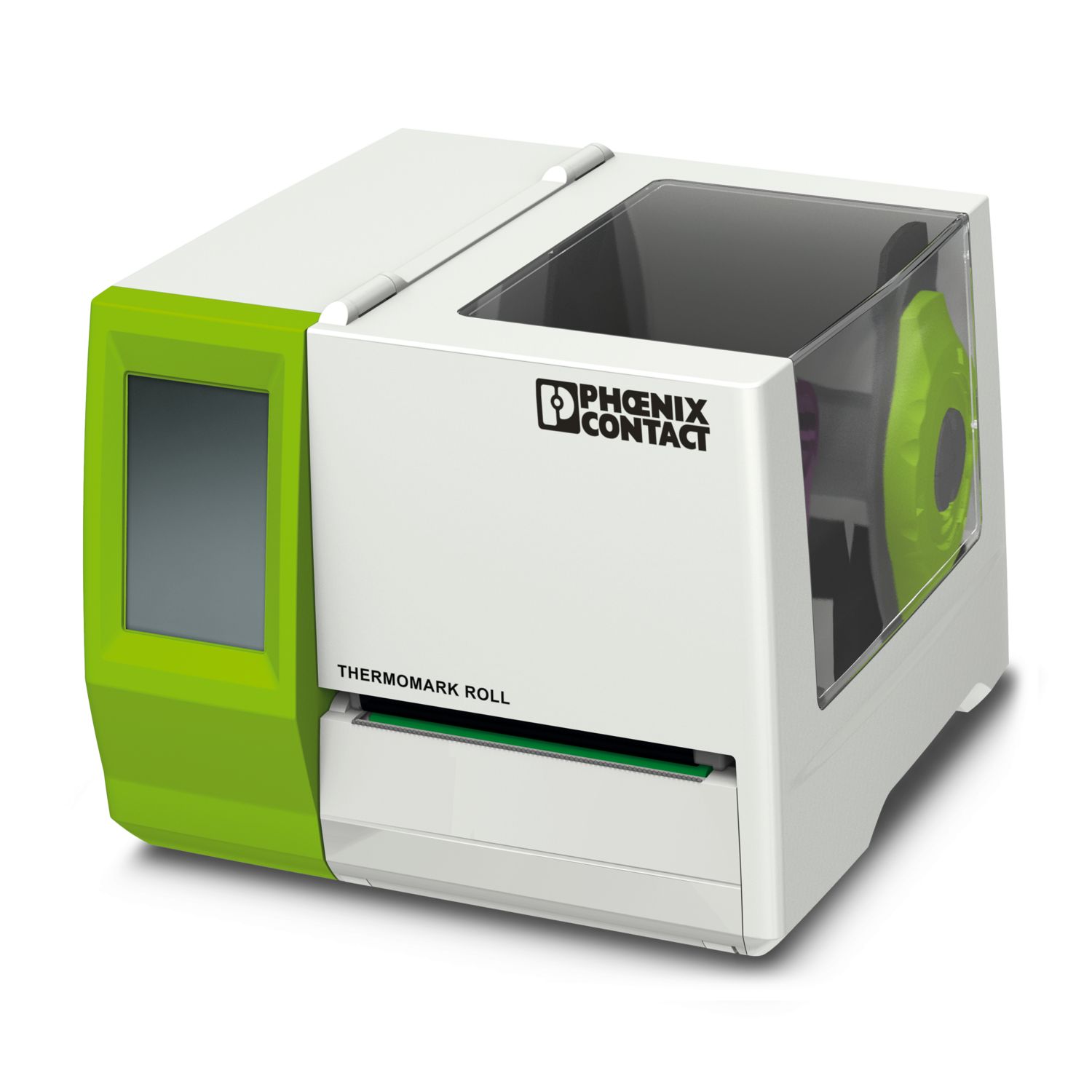

THERMOMARK ROLL - Thermal transfer printer 5146477

-

THERMOMARK X1.2 - Thermal transfer printer 5146231

Vantagens

The EML-RM label is ideal for temporary marking

This label features solid and reliable adhesion, but can also be easily removed again without any leftover residue. Once removed, it cannot be re-used

When combined with the right ink ribbon, the marking is highly resistant to solvents and mechanical influences

The EML-RM ... materials are UL-listed

Labeling service: Phoenix Contact can custom-label all EML-RM ... markers in accordance with your requirements

Phoenix Contact S.A.

Sintra Business Park, Edifício n°1 Zona Industrial da Abrunheira, sala 0M, 2710-089 SINTRA