UC-WMTBA-D (24X5)/PP YE

-

Detectable cable markers

1312765

Detectable cable markers, Sheet, yellow, unmarked, can be labeled with: TOPMARK LASER, TOPMARK NEO, mounting type: Assembly with cable ties, cable diameter: > 4 mm, Number of individual labels: 12, text field height: 5 mm, text field width: 24 mm

Detalhes dos produtos

Produtos compatíveis

Vantagens

The detectable UC-WMTBA-D ... UniCard marking family for the identification of cables and wires in controller manufacturing, systems manufacturing, and control cabinet building

The markings can be detected inductively, which makes them particularly suitable for use in the food and beverage industry

High durability of the marking materials as well as the labeling due to PP material and laser marking

Thanks to their angular shape the markers fit perfectly onto cables

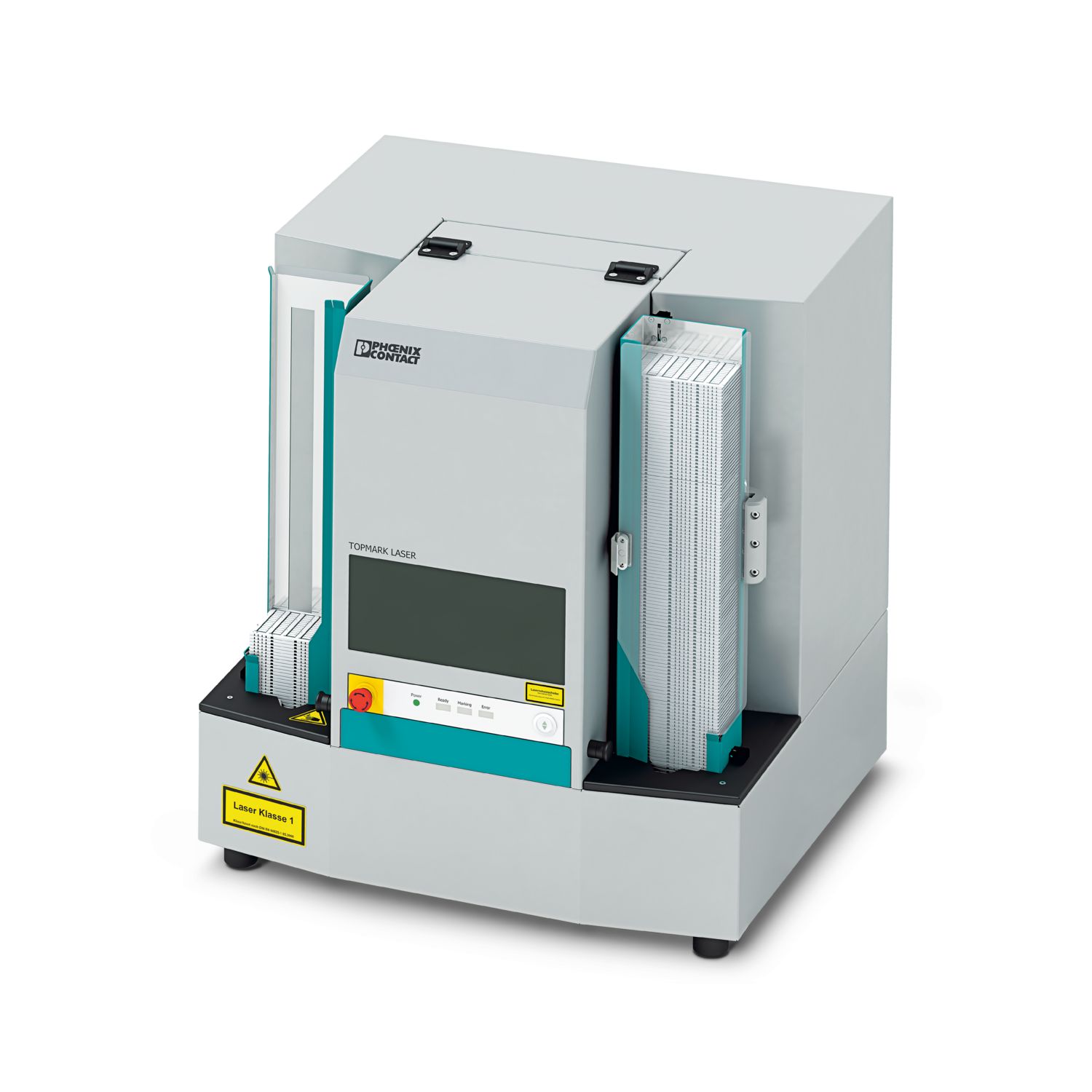

The markers, supplied in uniform sheets, can be marked quickly and easily using the TOPMARK LASER or TOPMARK NEO

The material used has been tested and approved by ISEGA for use in the food industry