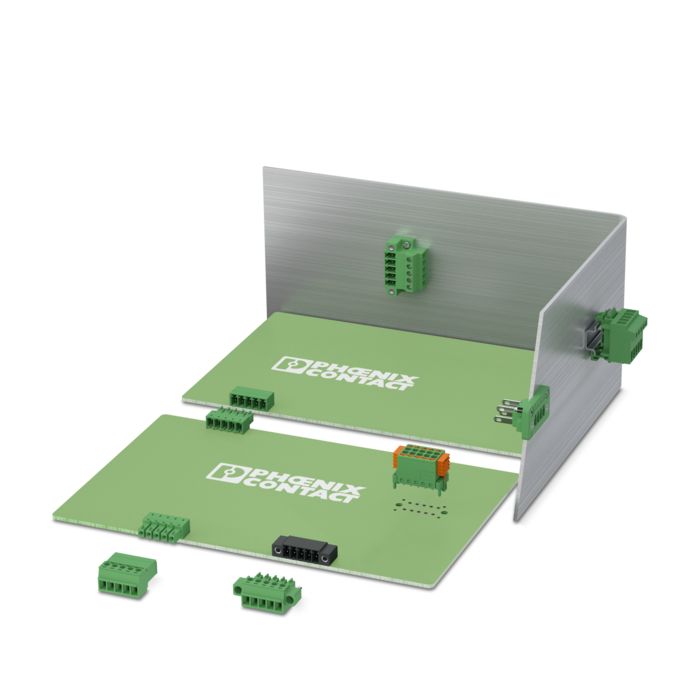

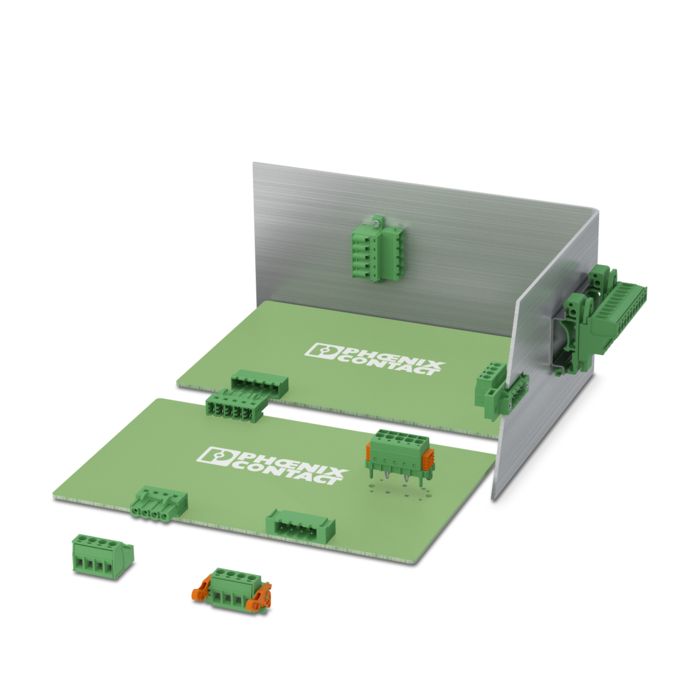

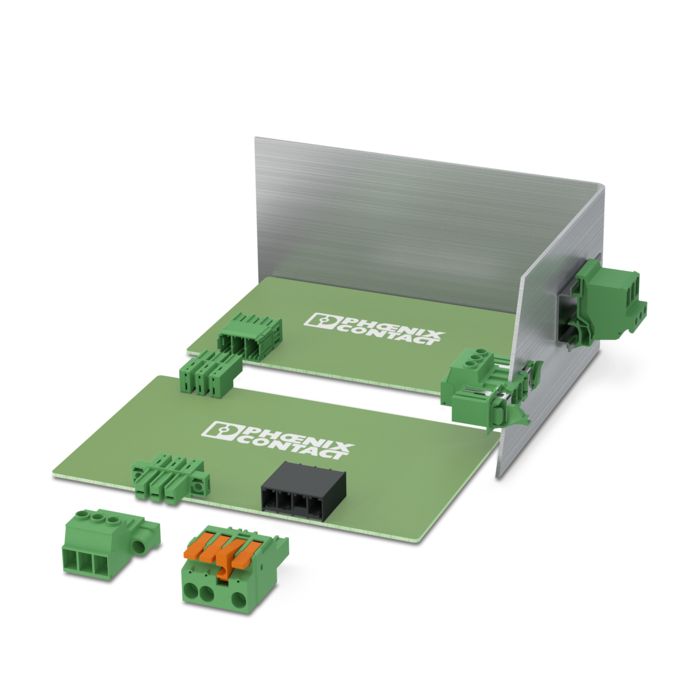

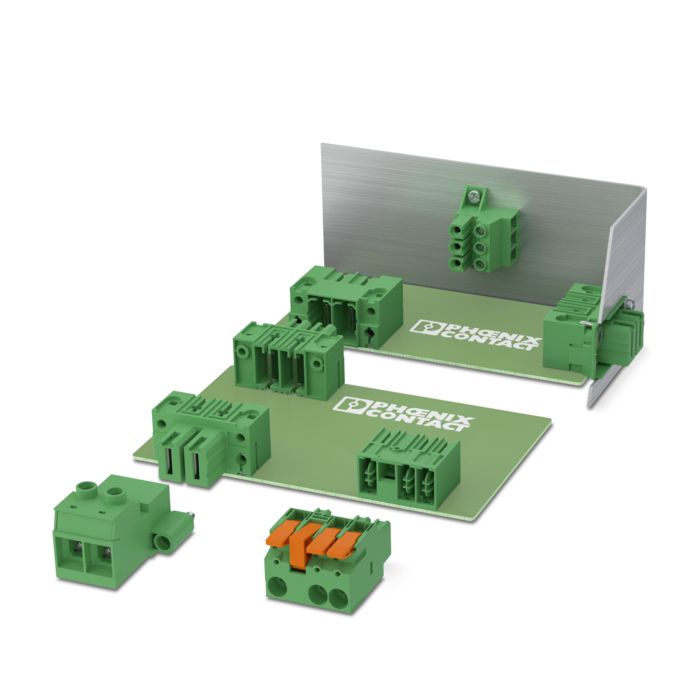

Main features

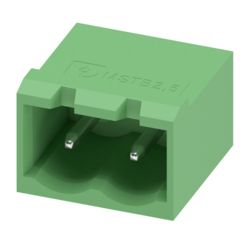

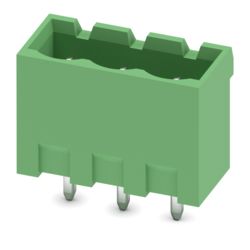

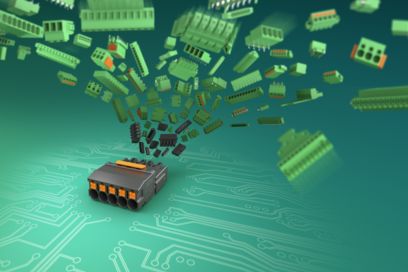

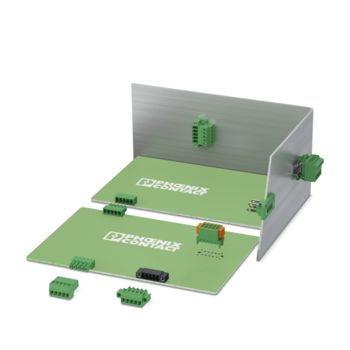

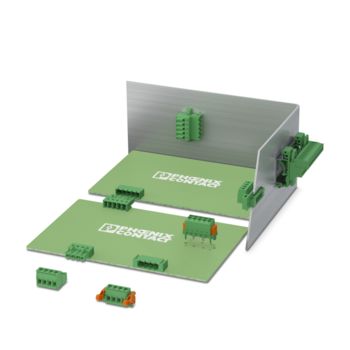

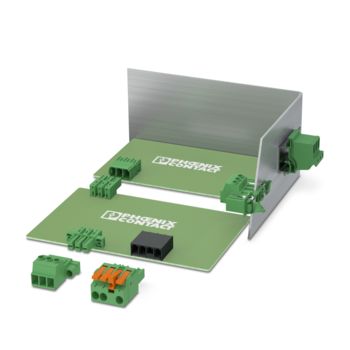

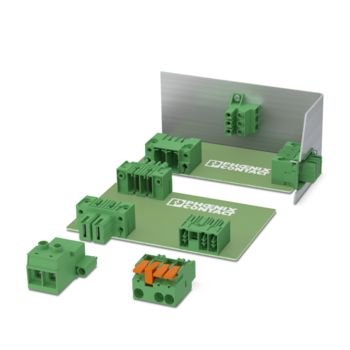

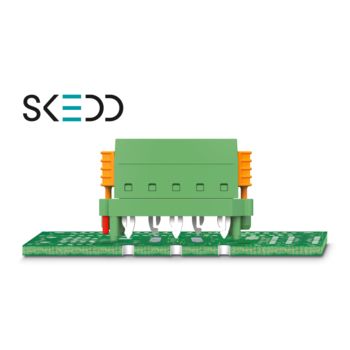

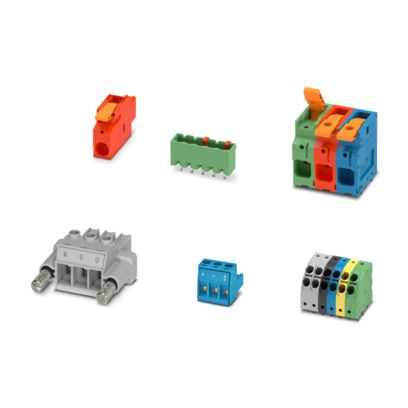

- For 2.5 to 3.5 mm pitch

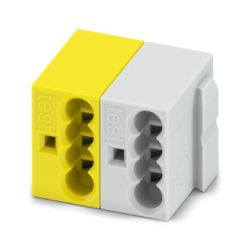

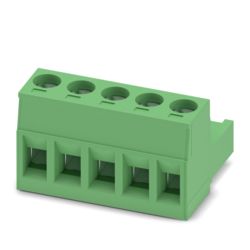

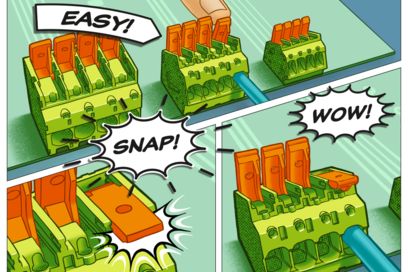

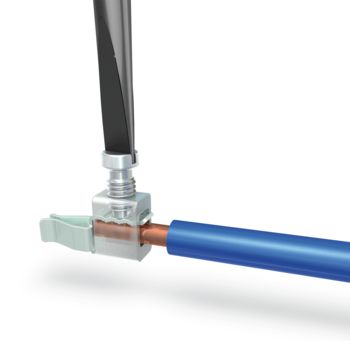

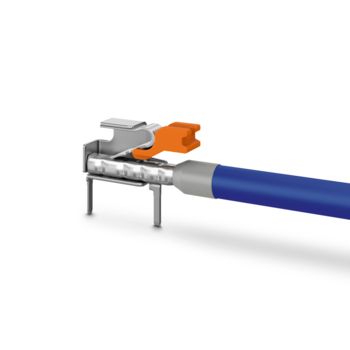

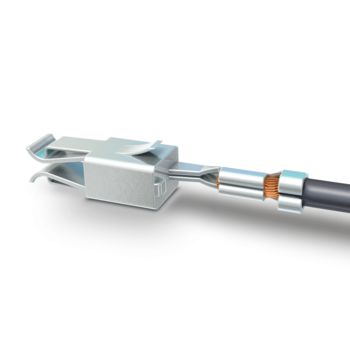

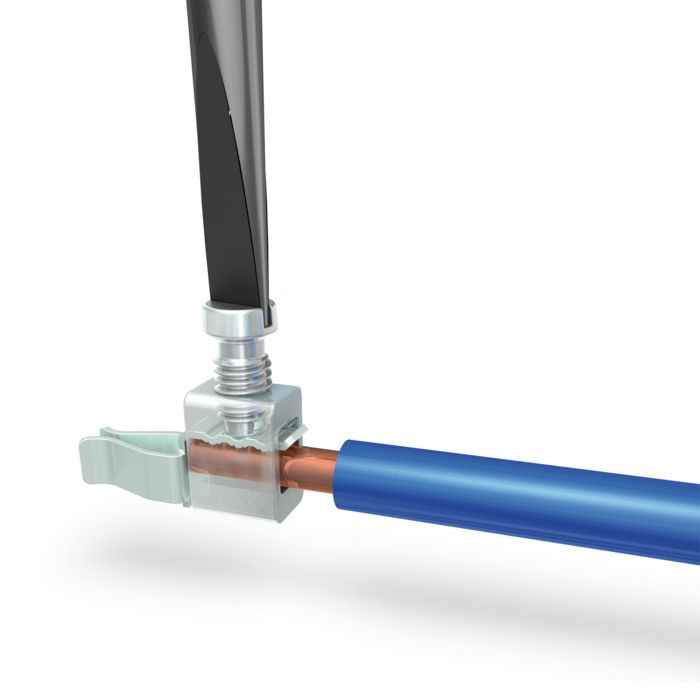

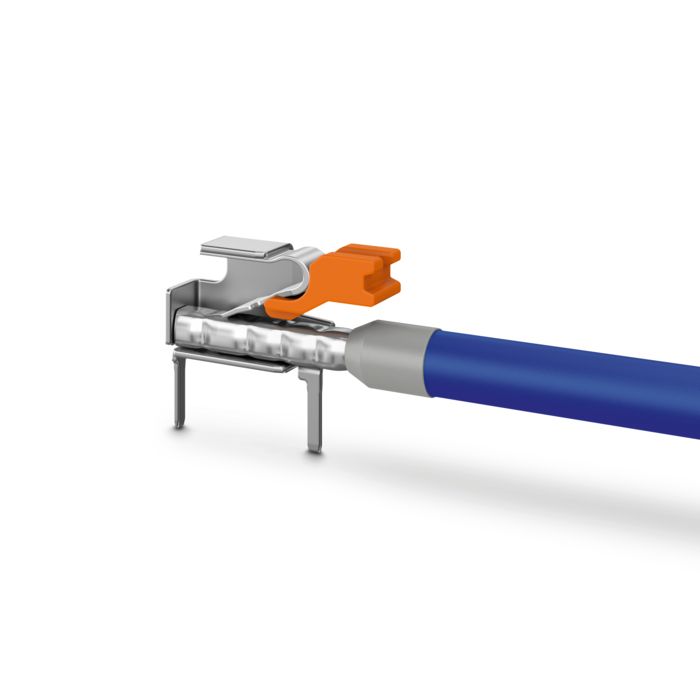

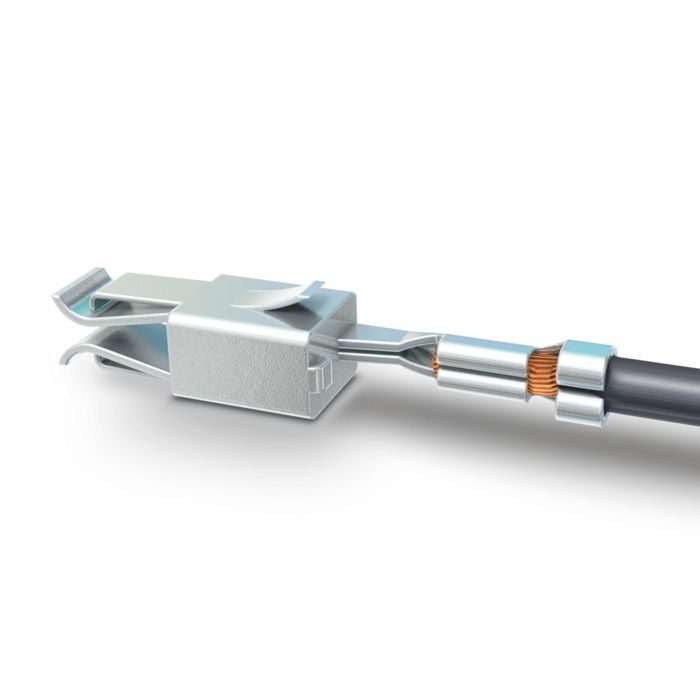

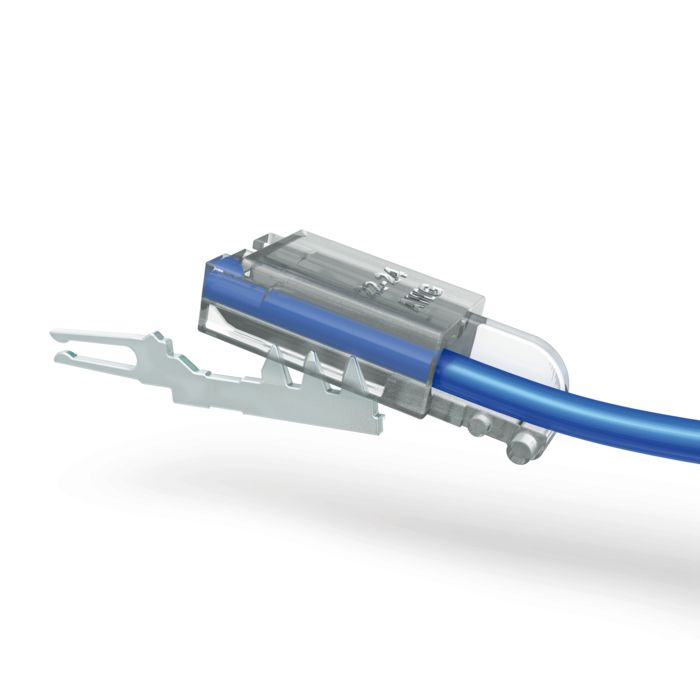

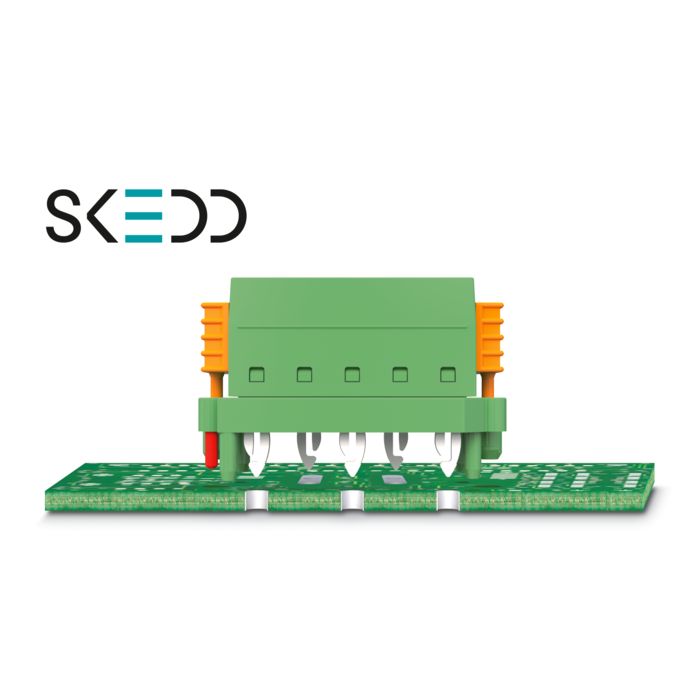

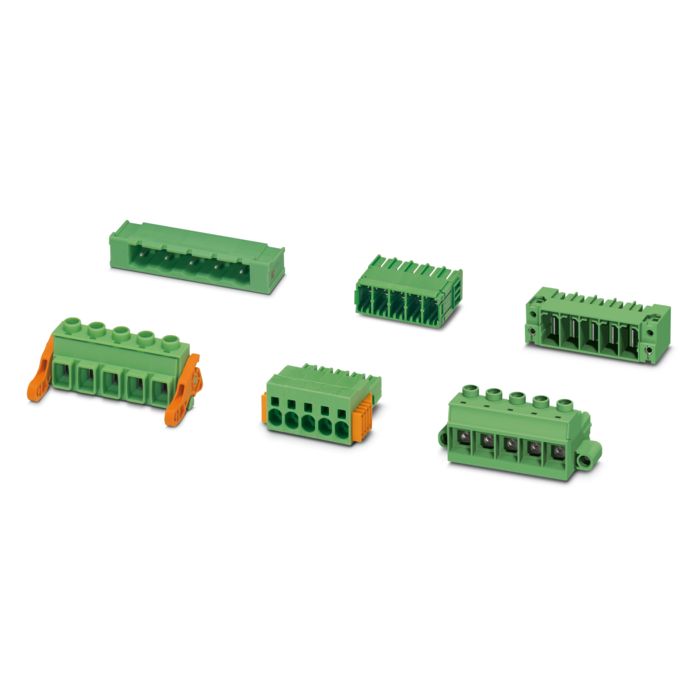

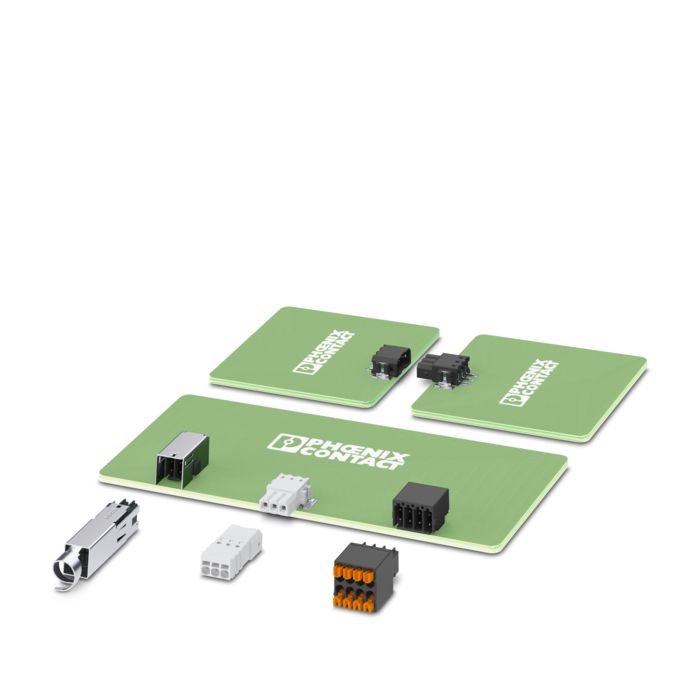

- Connection technologies with screw, Push-in spring, and crimp connection

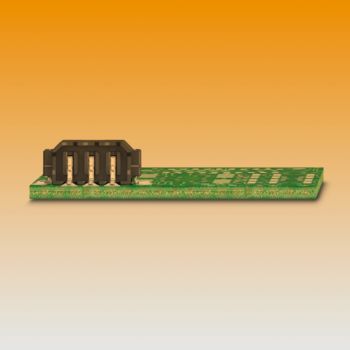

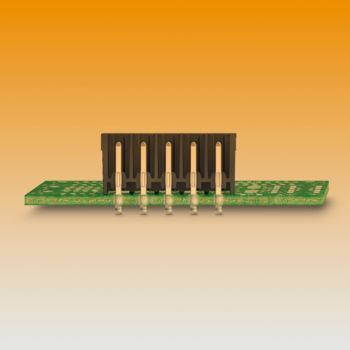

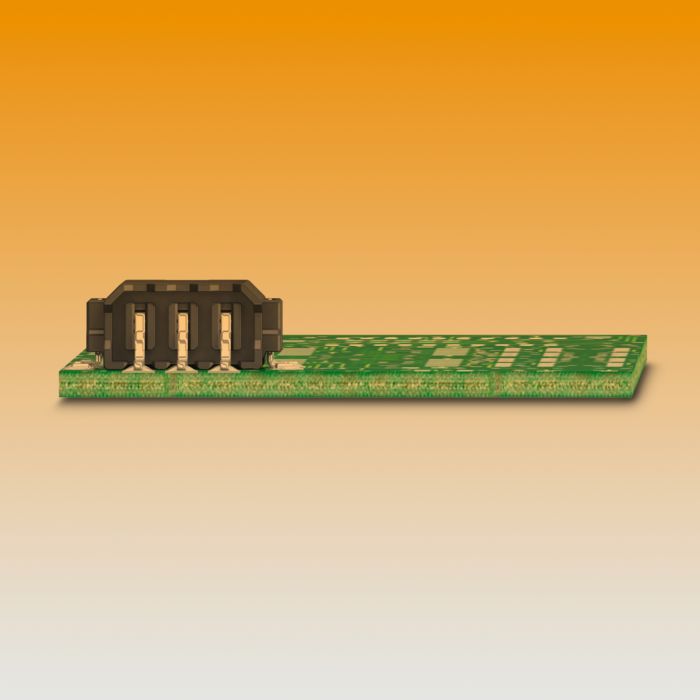

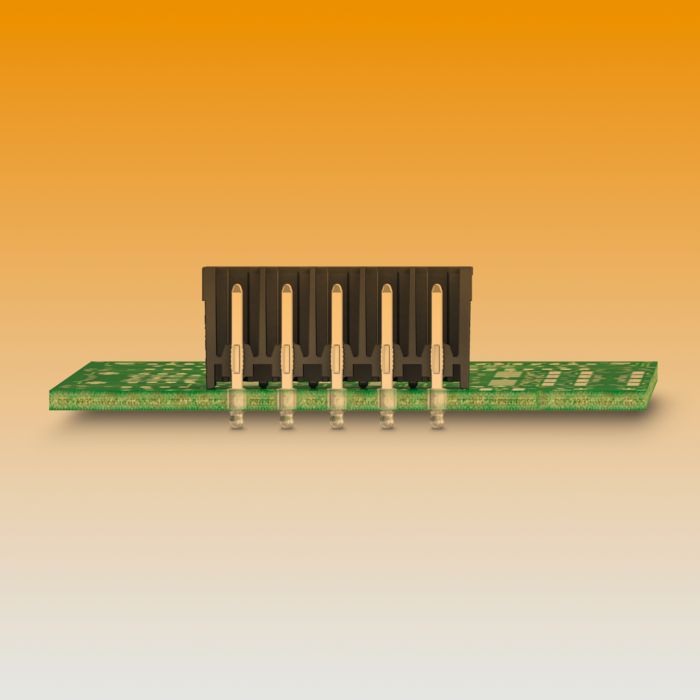

- Assembly of headers via wave or THR soldering

- Horizontal, vertical, and inverted versions of the connectors and headers

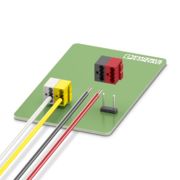

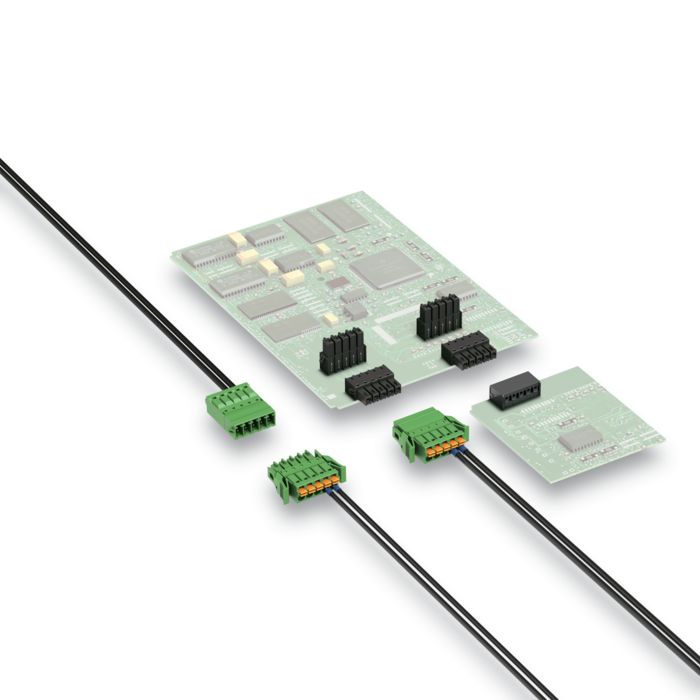

- Connectors for wire-to-board, board-to-board, and wire-to-wire

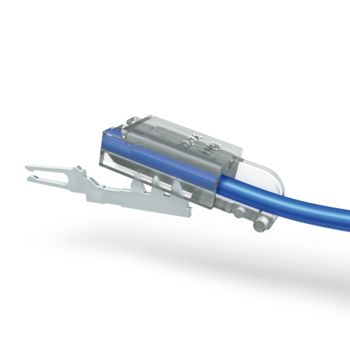

- Shielded versions for optimal data transmission