Mining

The requirements in the mining industry are high. High system availability and process quality are extremely important. At the same time, however, cost pressure is forcing mining companies to find new and more efficient ways to operate mines economically. Digitalization offers opportunities in the field of smart mining to ensure higher productivity and smooth operation.

Phoenix Contact is there to support you with many years of experience in connection and automation technology. Our broad product portfolio has proven itself worldwide for decades, even under the most demanding conditions, and thus meets the high requirements of the mining industry.

Our products for your requirements in the mining industry

Discover innovative products that deliver superior system availability, efficiency, and safety in addition to ensuring secure and reliable processing for your data. Using these products means being equipped today for the requirements of tomorrow in the field of smart mining.

Using a wireless system to monitor water levels efficiently in open-cast mining

A mine in South America is installing a Phoenix Contact wireless system to remotely monitor and control the water level within it, ensuring its employees benefit from safe working conditions.

Excellent processes from development through to delivery

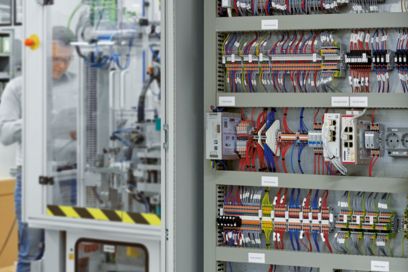

Innovative products and highly automated production processes require the highest level of systematically developed product and process quality. Corresponding processes ensure this quality from development through to series production.

Zero error strategy

Zero error strategy

Lean, error-free, and disturbance-free production processes without rejects or reworking are the goals we are continually striving for. To achieve these goals, we are integrating advanced quality planning early on in product and process development. In series production, operational quality assurance monitors processes and organizations, while Supplier Quality Engineering actively integrates the suppliers. This allows us to ensure flawless products that meet market requirements and specifications.

Advanced quality planning

Advanced quality planning

Systematically and using modern methods, we convert our customers’ product requirements into process and quality requirements right from the start of a development project. After risk analysis, we design and qualify a corresponding test concept based on the production control plan. Processes and products are qualified following conventional industrial standards and procedures.

Operational quality assurance

Operational quality assurance

We are continuously monitoring, scrutinizing, and optimizing our production processes. While doing so, it is important that we apply the experience and knowledge of our employees so that the entire company is motivated to continuously improve. Quality circles, 8D methodology, process audits, and the use of statistical methods for assessing processes and solving problems also help keep quality, costs, and delivery dates continuously in line with one another.

Supplier quality engineering

Supplier quality engineering

Integrating suppliers and vendors early on in the process ensures our product and process quality as well as our capacity to deliver. The tasks involved in Supplier Quality Engineering (SQE) include the management of qualification programs along with complaint processing and production part acceptances in cooperation with our suppliers. Integrated into a tight network consisting of Purchasing, Production, and Product and Process Development, SQE contributes globally to our high quality standard.