Conductor and cable marking

Our marking material is suitable for a variety of applications in industrial environments, from control cabinet marking right through to outdoor systems. The durability of the marked materials, even under extreme conditions, satisfies all international standards and requirements. A wide range of versions are available for terminal marking, wire and cable marking, equipment marking, and plant marking.

The MARKING Configurator features a particularly high degree of user-friendliness and flexibility when it comes to the individual marking of marking materials. The ordering process is designed to be simple, transparent, and completely digitalized – starting from a batch size of one.

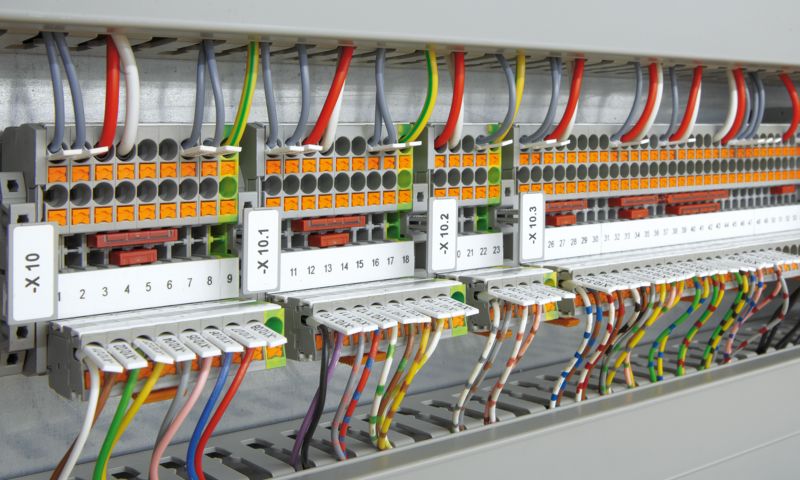

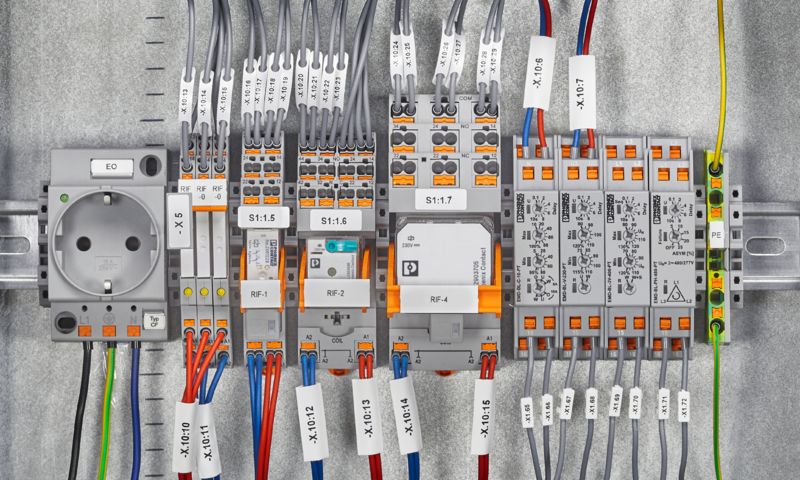

Marked terminal strip

Large-surface and clear marking of terminal points is essential for the quick and error-free wiring of terminal strips. In particular, they simplify the startup and maintenance of control cabinets and systems. Terminal strips are assembled flexibly with different terminal blocks whose geometries can differ from each other. The decisive variables for the terminal markings are the pitch and marker groove. Phoenix Contact provides a comprehensive range of versions that allow secure positioning on the terminal blocks.

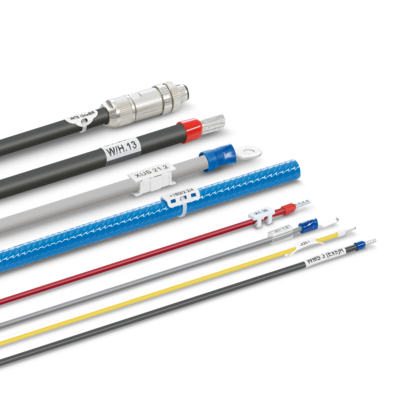

Materials for wire and cable identification

Standard-compliant, permanent wire and cable marking ensures the quality standard. To achieve this, different wire and cable diameters require precise matching of the appropriate marking material. Selecting the appropriate mounting type is crucial here. Mounting with cable ties is not dependent on the wire or cable diameter, and can also be performed after wiring. Subsequent marking is also possible using clip-on or adhesive markers. Identification with thread-on markers, however, must be performed prior to wiring.

Equipment identification

Whether in the control cabinet, in production plants, in the field, or in outdoor installations – equipment markings are used everywhere. This multitude of applications places numerous demands on the markings used, which can only be met with specialized materials and special adhesives. For uneven surfaces, for example, highly flexible PVC labels that adjust perfectly to the surface are ideal. On the other hand, only marking materials with special and particularly strong adhesives will bond to rough and low-energy surfaces.

Warning, mandatory, and prohibition sign for plant identification

The comprehensive and clear identification of plants not only guarantees safety, but is also a legal requirement. Along with warning information, prohibition signs, and mandatory signs, the identification points out emergency stop buttons and fire alarm systems, for example. Identification with hazardous substance labels in accordance with the international standard ensures the necessary protection when handling hazardous substances. Furthermore, pipeline markers are used to indicate which fluids or gases are flowing in the pipes, as well as the direction of flow.