Innovative marking systems

Whether it‘s a laser marking system, UV LED printer, or thermal transfer printer, the right marking system is available to meet all of your requirements in terms of application, location of use, and marking durability. Create markings right where they are needed with our innovative stationary and mobile marking systems. For example, you can simply print the appropriate marking on site in the maintenance facility. With the THERMOMARK E SERIES modular marking system, you can now make your marking process even more efficient.

Shrink sleeves for conductors and cables in rail vehicle installations

WMS-2 HF shrink sleeves are ideal for railway applications. They are halogen-free, conform to hazard levels HL1 to HL3, and satisfy requirements R22 to R24 of DIN EN 45545-2. In addition, they are designed for a wide temperature range.

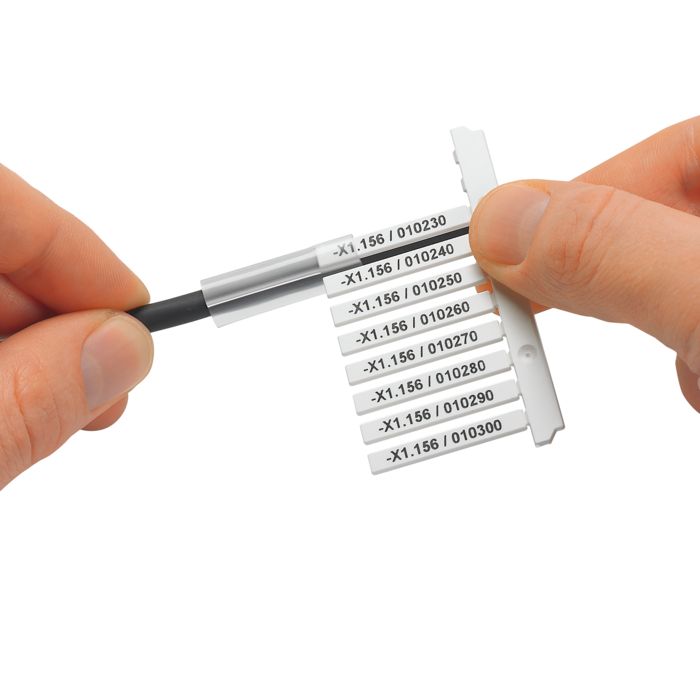

Marker carriers and metal labels for railway technology

You can use the cable markers from the PATG HF product family to mark conductors and cables during installation in rail vehicles. The processed TPU conforms to fire protection class UL 94 V0 and is designed for a wide temperature range. For marking purposes, you can add insert labels in UniCard format to PATG HF cable markers.

Our metal labels for wire and cable identification and for device and plant marking are extremely resistant and weatherproof.

Marking materials in UniCard format

Be it terminal, wire, cable, or equipment marking, our marking materials in UniCard format provide you with the appropriate materials for use in rail vehicles. Our UC and UCT product families are based on the UniCard format, which can be marked using a card printer. The UCT product family is compatible with all three printing technologies. Both product families conform to hazard levels HL1 to HL3 and satisfy requirements R22 to R24 of DIN EN 45545-2.

Hand tools and automatic devices for train installations

Whether for manual or automated processing – we have the right solution for cutting, removing the sheath, stripping, crimping, mounting, and measurement. Along with standard tools and automatic devices, our comprehensive range of tools features special hand tools for the particular challenges faced in the railway industry.