Automating an all-in-one hydrogen energy storage solution for Endua A scalable control and safety system improves the control and information availability of a modular hydrogen energy storage system. At the same time, the total cost of ownership is reduced.

Customer profile

Innovative hydrogen technologies by Endua

Endua is a Brisbane-based company focused on developing hydrogen-powered energy storage solutions. Its goal is to provide clean, reliable, and long-term energy storage for remote industries, communities, and off-grid energy consumers.

The power bank technology from Endua is a modular system based on water electrolysis. The hydrogen is stored and, when required, used for power generation by providing electrical energy via fuel cells. The system is self-sufficient and enables the user to generate, store, and use hydrogen, all in one location.

The power bank solution offers both flexibility and extendibility. Customers can adapt the size of the electrolyzer, the storage capacity, and the size of the fuel cell independently. Several units can be connected in parallel to increase the capacity. In addition, the power bank can be integrated into renewable energy systems very easily.

The challenge

Scalability and worldwide support

The power banks need a reliable, scalable, and precise control and safety system. The development of the safety logic had to be simple and require minimal programming knowledge. In addition, the controllers had to be flexible and easy to adapt to different requirements.

As with any other system, regular maintenance is required for the power banks, even when they are installed in remote areas. This includes, for example, the user maintaining the water and air filters and licensed tradespeople calibrating the gas sensors. The PEM electrolyzer stacks are replaced on-site. The efficiency losses of the electrolyzers must also be monitored.

Endua was therefore looking for a partner that would provide a scalable solution, backed up by worldwide support. In order to minimize the design and procurement effort, almost all the equipment for the control cabinet had to come from one provider.

The solution

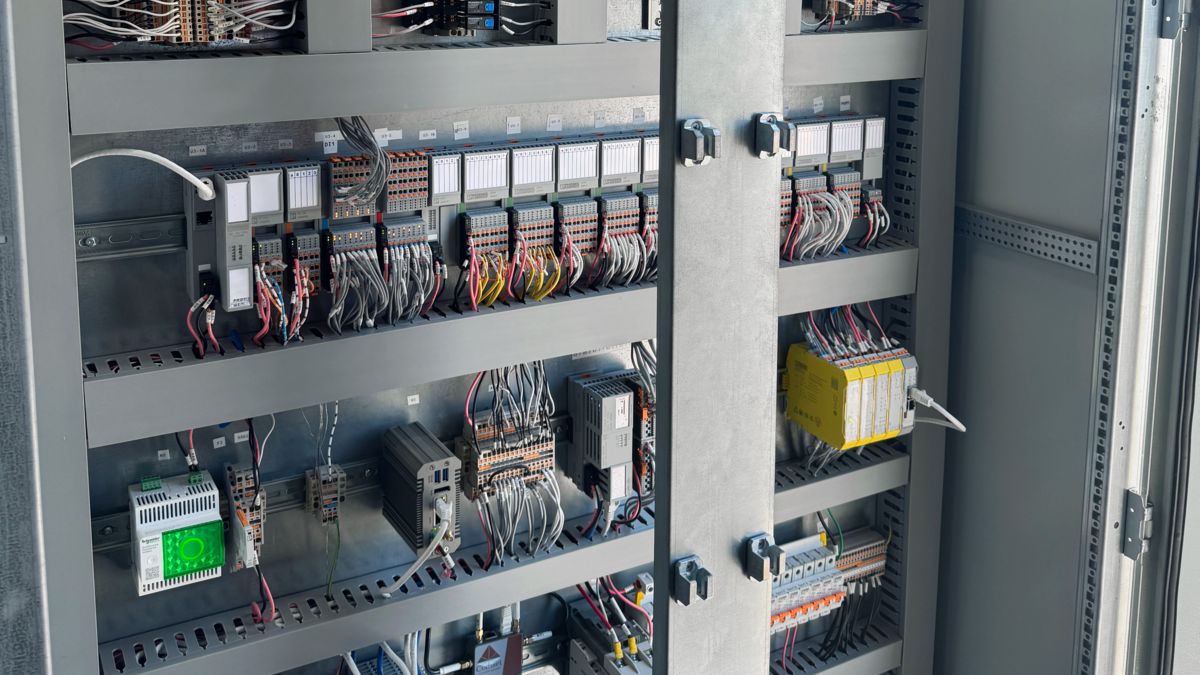

Equipping the control cabinet

The control cabinet of the power bank systems is equipped with many of our electrical and control components. These include PLCs, safety controllers, IPCs, surge protection, cables, terminal blocks, lighting, I/O systems, Ethernet switches, and communication gateways.

Our open PLCnext Technology control system supports programming with high-level languages as well as classic IEC 61131-3 languages. Furthermore, it can be extended with modules from the Axioline I/O system.

The configurable PSR safety modules are supplied with TÜV-certified software. This meant that Endua was able to develop the safety logic with minimal programming knowledge. With the modular design, the controllers can be adapted easily and flexibly to the respective requirements.

Proactive maintenance in the cloud

Our IPC and communication hardware enables the power banks to be monitored remotely via a cloud-based infrastructure. The industrial PC converts the data from the control system into the MQTT protocol and sends it to a cloud server. This means that the performance of the power bank components can be recorded over their entire service life and maintenance can be planned in advance. This is particularly important for those systems being used in remote areas.

Consulting services

Endua and the Phoenix Contact Sales Team worked closely together to develop the control and security system for the power bank. As a result of this, obstacles arising during software development and commissioning were quickly overcome. One example of this is the optimization of the detection of hydrogen leaks. This very close collaboration significantly accelerated the project execution.

Contact person

Products

Still haven’t found the right product?

Feel free to contact us. Together, we can find an ideal solution for equipping your control cabinets with more than 100,000 products from the fields of connection, communication, and automation technology.

Summary

Future plans: system enhancements

The integrated PLCnext Control solution with safety offers a range of advantages over the original power bank configuration. Endua aims to increase operational efficiency, save costs, and ensure a safer working environment through the use of an innovative integrated solution. With the goal of improving internal research and development capacities, Endua is working on a second-generation test system. To this end, the PLCnext Control is used to combine PLC technology, safety technology, and IPC technology in a single unit.

The upgraded system is an enormous step forward for the Endua safety system. It enables improved control and information availability of the entire system, while reducing the total cost of ownership. The PLCnext Engineer software enables the user to program directly from the operator terminal and upload the results to the controller. This speeds up the programming, testing, and modification of the safety system. At the same time, it enables additional input directly into the control and information system.

Would you like to find out more details about the application? Then download our free document with all the details regarding the customer application here.