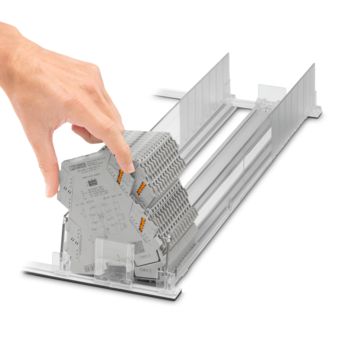

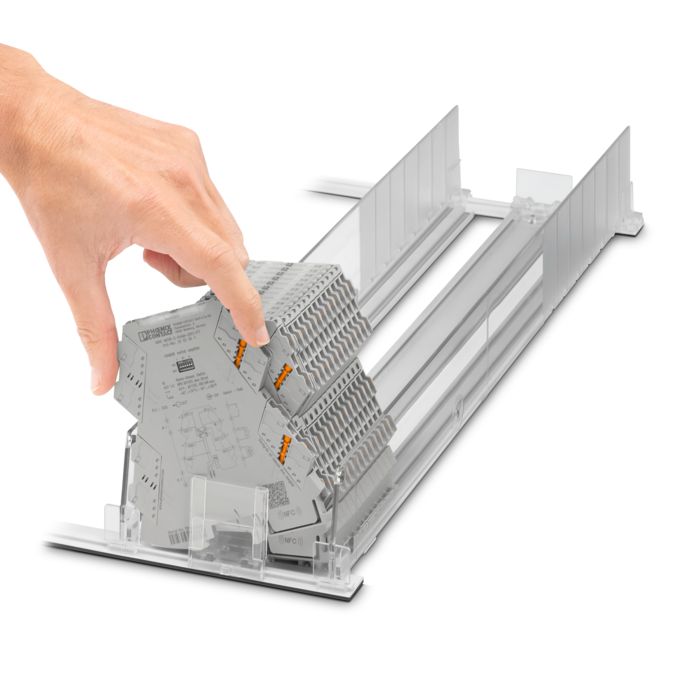

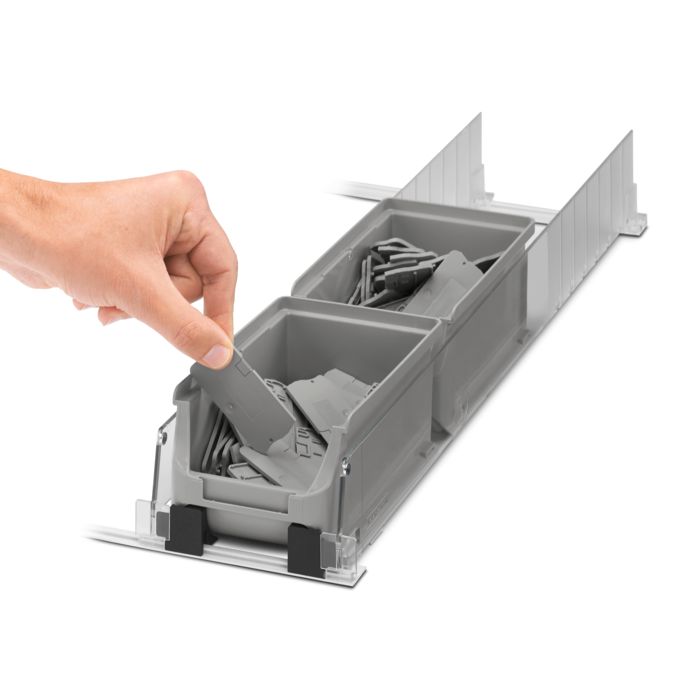

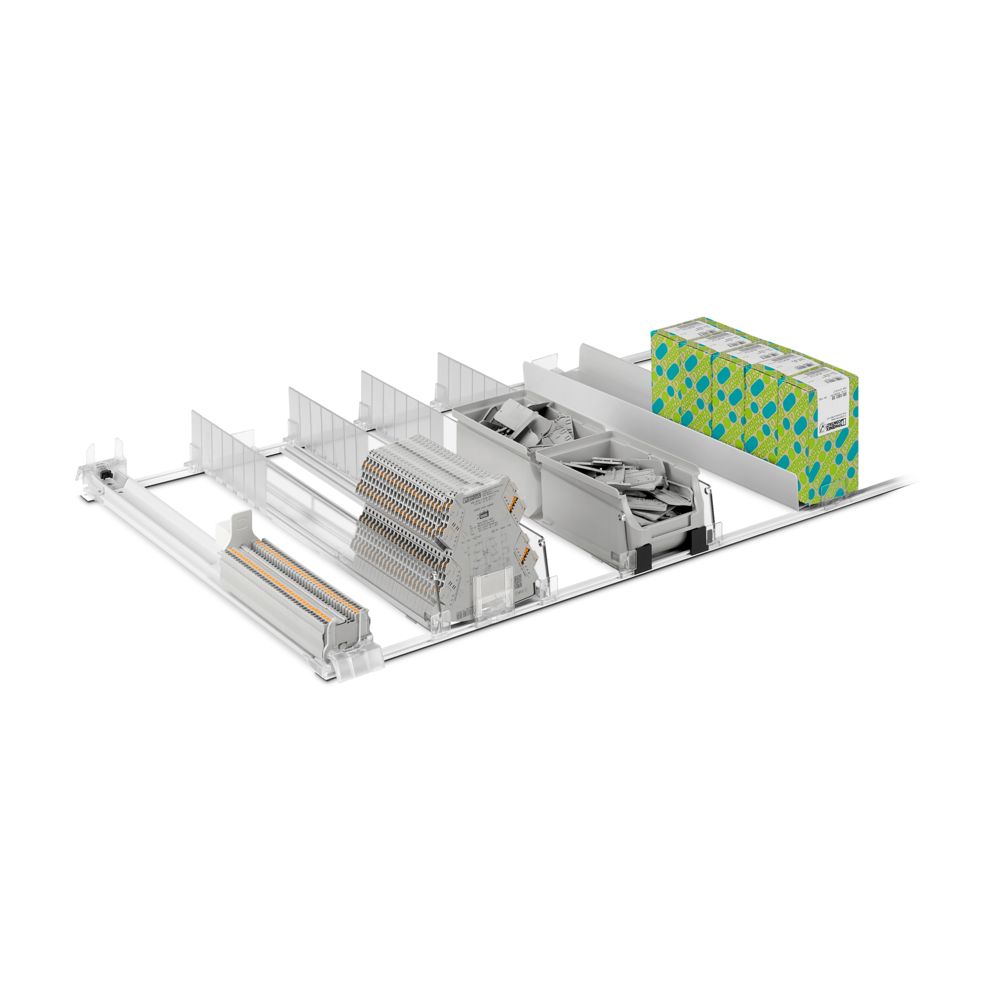

Quickly and easily combine our basic workstation with the appropriate accessories and tools, such as our profile and DIN rail cutters. You can not only use them to cut standard DIN rails and cable ducts quickly and precisely, but also without chips and without burrs. The basic workstation is equipped with a bracket for attaching a clipboard or monitor, for example. In addition, the lower area provides storage space for a variety of DIN rails or cable ducts. The brackets already installed on the frame ensure a hold. Using our zero-cut block when manually cutting perforated DIN rails provides further time savings. The zero-cut block enables fast and reproducible zero cuts with just one setting and without time-consuming, repeated measurement. This means that you can achieve an optimally coordinated and tidy workstation for manual mechanical processing with minimal effort.