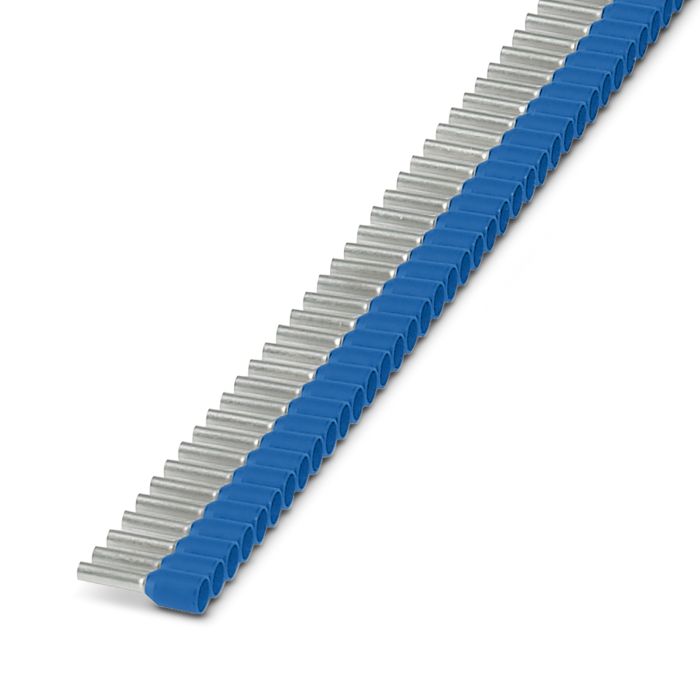

The non-insulated sleeves are primarily used in confined environments. They protect the conductor and facilitate further processing.

- In accordance with DIN 46228-1 and UL 486F-A

- Available in several length variants

- Conductor cross-sections from 0.14 to 120 mm²