Energy monitoring in process technology systems The comprehensive condition monitoring of equipment saves energy costs and increases system availability. Detect potential damage at an early stage and optimize your processes.

The challenge

Planning maintenance intelligently

A large proportion of unplanned failures are caused by energy loads, such as rotating equipment. In this case, equipment such as pumps, compressors, and agitators are damaged. Maintenance of these elements is often carried out too early or, in some cases, too late, resulting in production downtime.

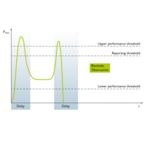

With permanent motor and pump monitoring, you focus on the relevant signs of wear and satisfy the prerequisites for predictive maintenance. Armed with this information, a pending failure can be predicted and maintenance performed at exactly the right time. Moreover, you have access to information on the state of health of your system parts at all times.

The solution

Early detection of defects and malfunctions

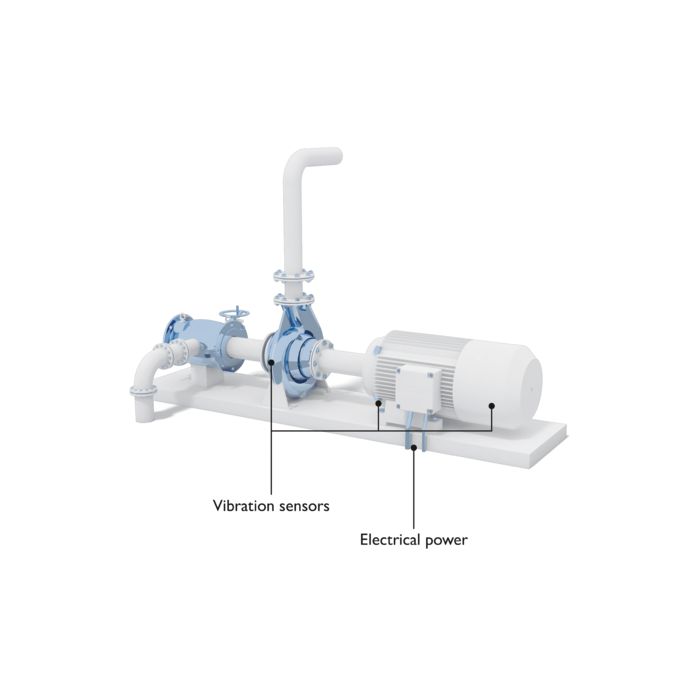

With permanent monitoring of critical pumps and motors, we enable you to perform maintenance at precisely the right time. Depending on the size and type of machine, hydraulic, mechanical, or electrical monitoring may be useful.

The electrical power provides information regarding the run, state, and operating point of the system parts. The monitoring system can be retrofitted quickly and cost-effectively and is therefore also suitable for smaller or medium-sized pumps and motors.

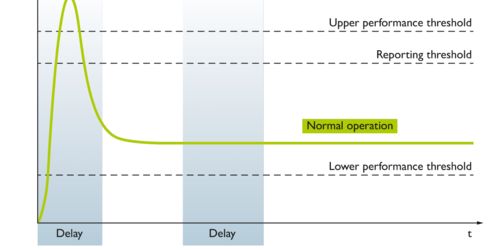

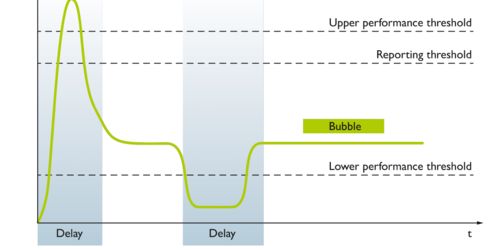

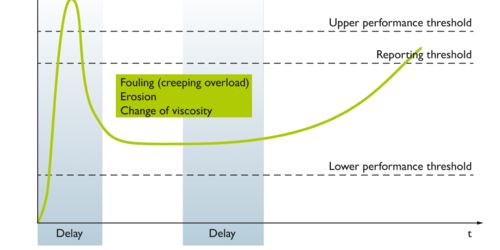

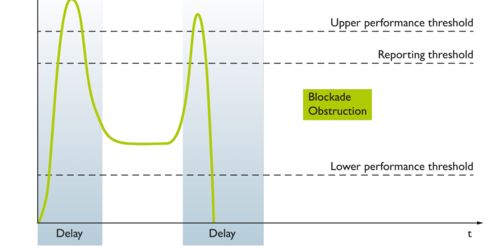

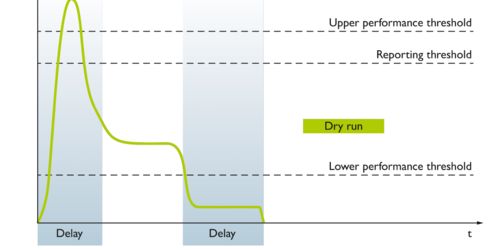

The active power characteristic can be used to identify numerous error patterns, allowing maintenance to be performed at the right time.

Effective motor and pump monitoring

Motor operating values are recorded using the electrical active power via current and voltage measurement. For three-phase machinery, this is possible in combination with a direct circuit, a contactor, or a frequency converter.

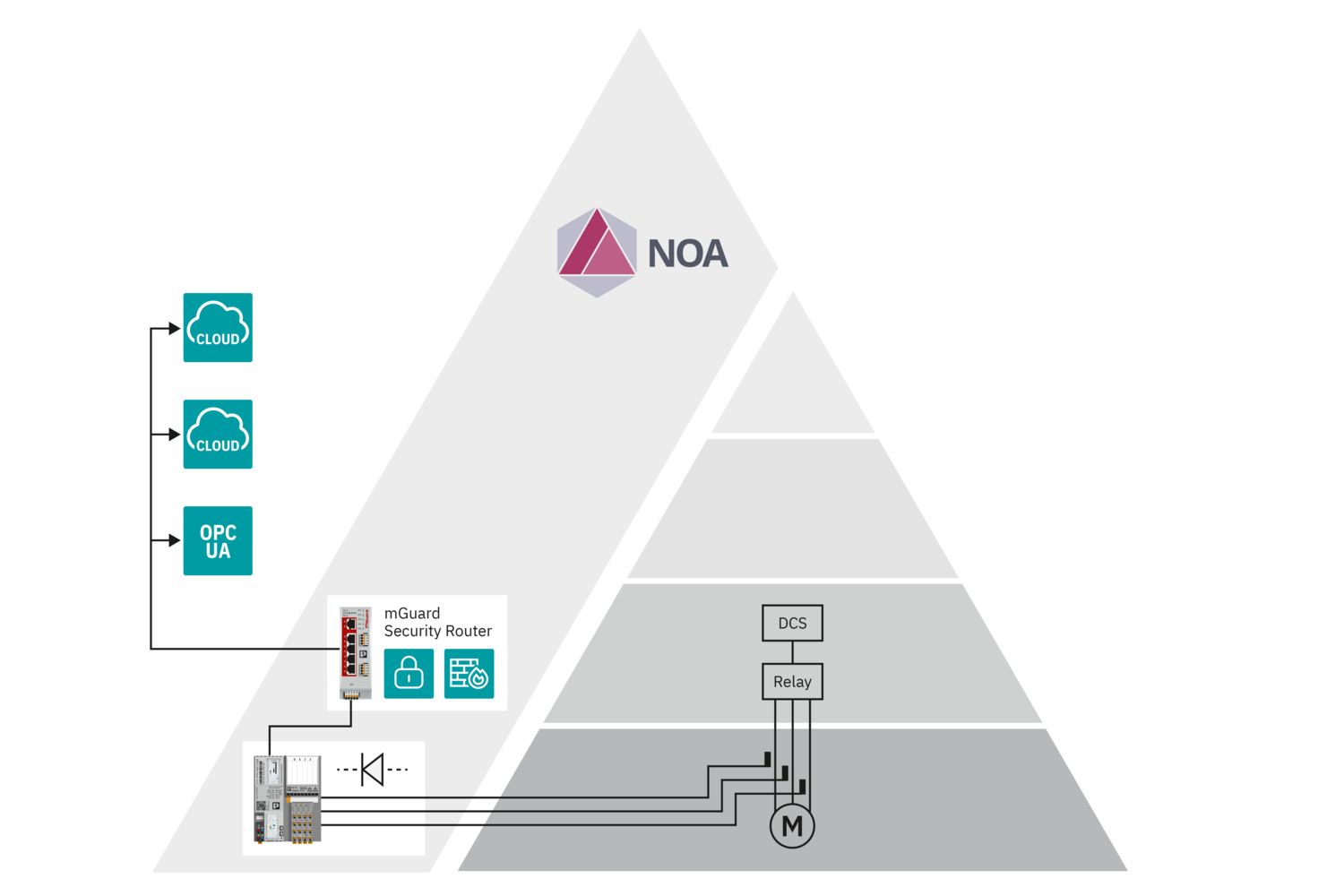

If additional sensors are used for monitoring, the monitoring model will be fine-tuned even further. The transfer can take place in one or more higher-level systems, such as databases, clouds, MES, and asset management. This ensures that the production process is not impacted.

Your advantages

- Reduced installation effort and easy retrofitting of active power measurement for monitoring rotating equipment, for example

- Minimization of maintenance and repair work with predictive maintenance through smart use of electrical variables

- Further increase in system availability with optional vibration monitoring

Contact

Products

Still haven’t found the right product?

Feel free to contact us. We will consult with you to find the ideal solution together.