Level monitoring Ensure the permanent monitoring of your tank levels with SIL-certified technology and Ex approvals.

The challenge

Reliable monitoring of fill levels

Tank farms typically consist of different sized tanks, sometimes with a storage capacity of more than 30,000 m³. Continuous monitoring as tanks are being filled and emptied, including functionally safe overflow protection, helps ensure reliable environmental protection.

The solution

Transmit measured values cost-effectively and safely over long distances

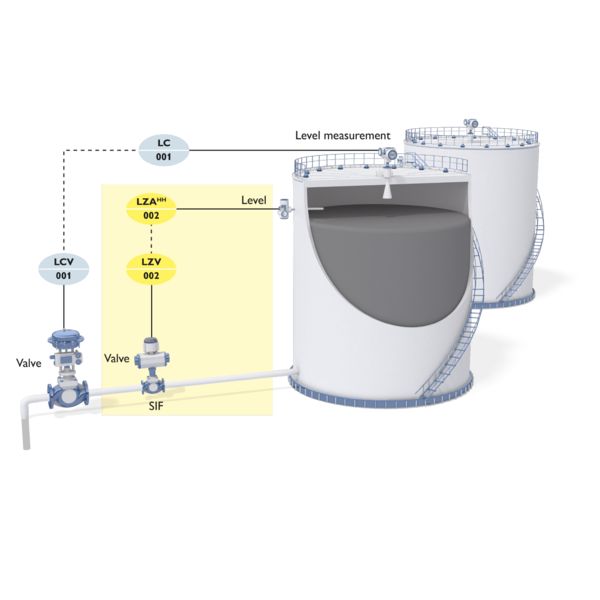

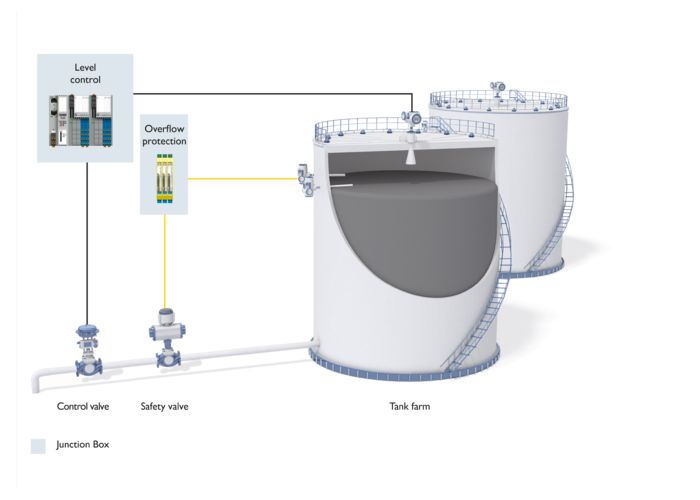

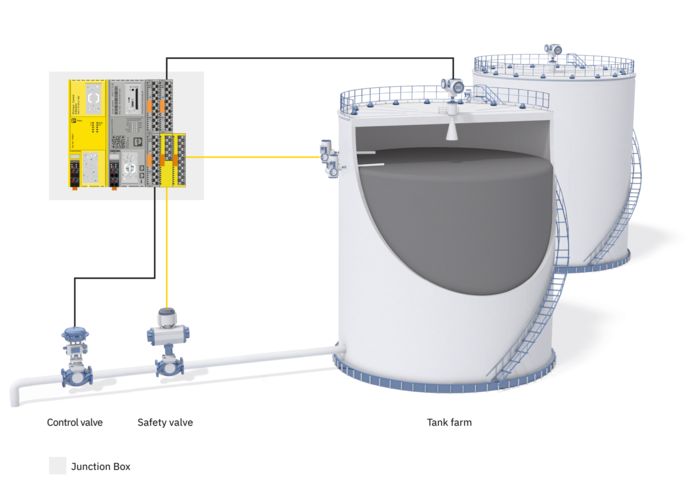

With our solution for level monitoring, you not only keep an eye on the fill levels at all times, but also on measured values such as the temperature and pressure. A system of various sensors, some in the Ex area, records the corresponding measured values.

We create an appropriate solution concept for you that includes the control, communication, and connection technology (which is also SIL-compliant), so that you can transmit, process, and quickly respond to Ex and non-Ex signals.

Immediate detection of errors

Functional safety sensors measure the fill level and signal dangerous states.

Safe limit value relays are used to interrupt the control of the inlet valve. The flow into the tank is stopped reliably by spring-closing safety valves, thereby preventing overflow.

Scalable automation modules for tank monitoring

You can create an efficient fill-level control system with the wide range of SIL-certified technology for functional safety, Ex i signal conditioners, and modular control systems. In addition to the fill-level control system, an overfill protection device is installed that controls the safety valve in the event of an emergency and stops the flow into the tank.

Contact

Products

Still haven’t found the right product?

Feel free to contact us. We will consult with you to find the ideal solution together.