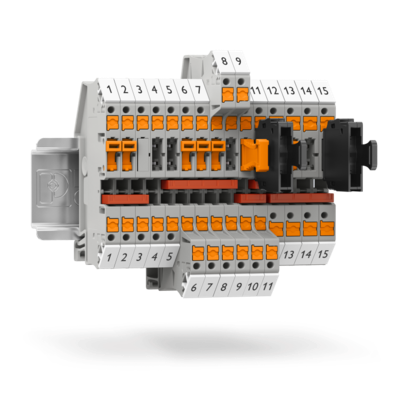

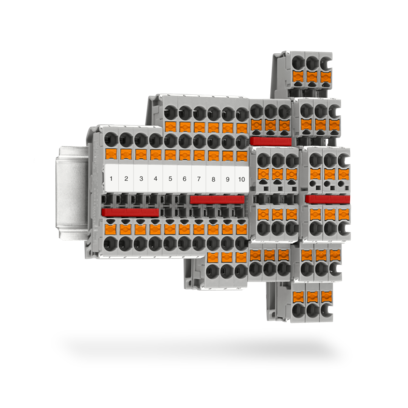

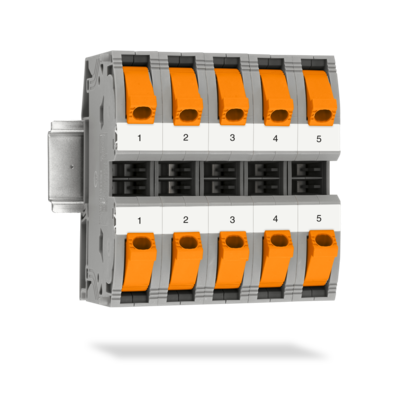

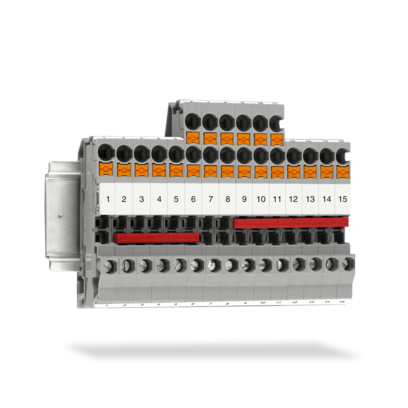

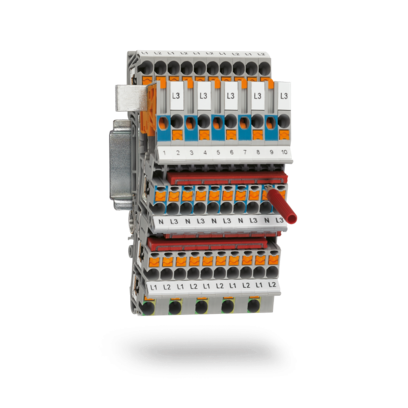

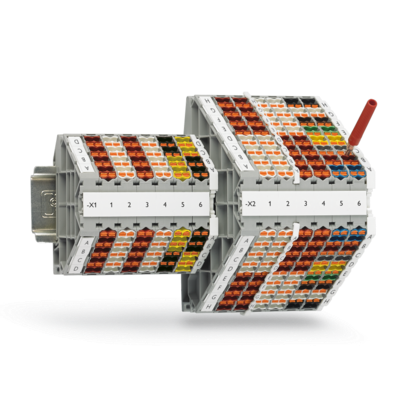

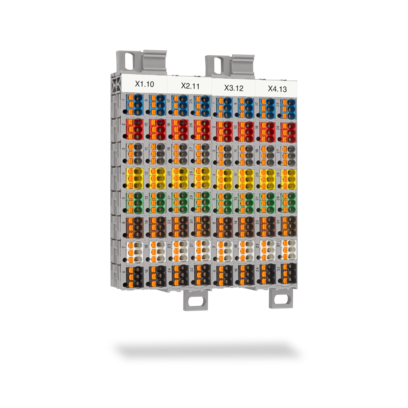

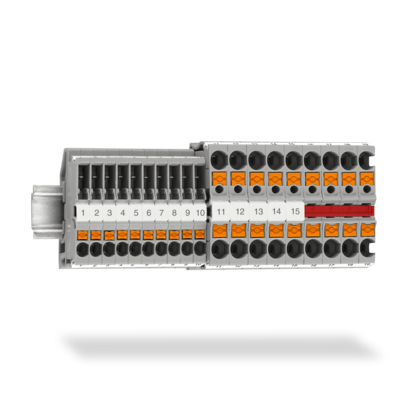

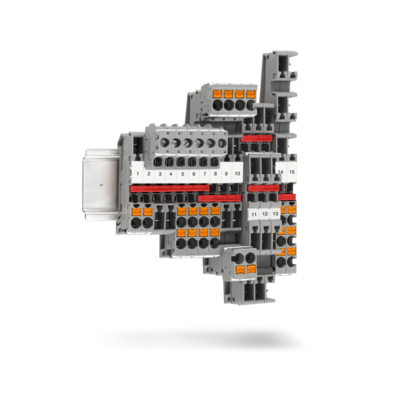

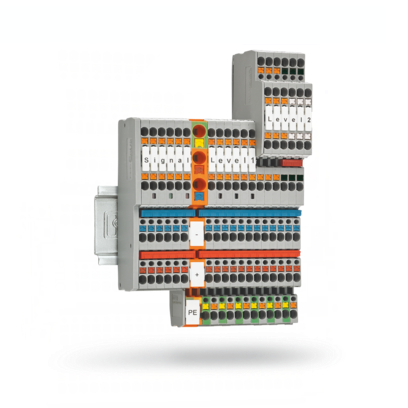

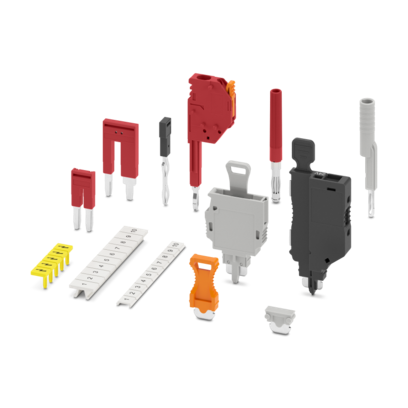

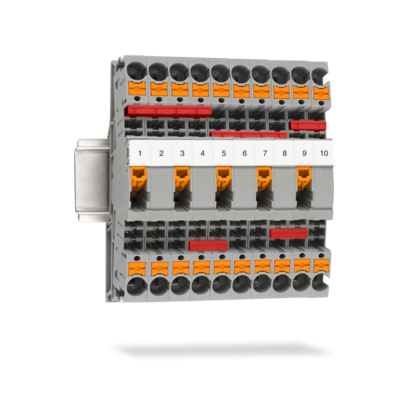

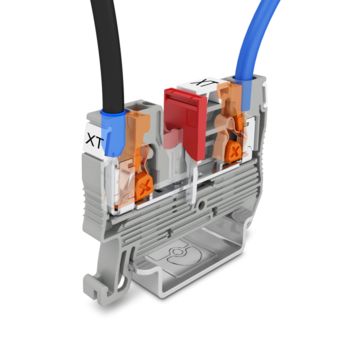

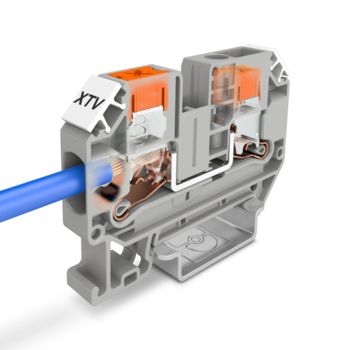

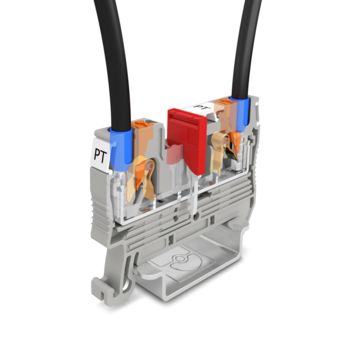

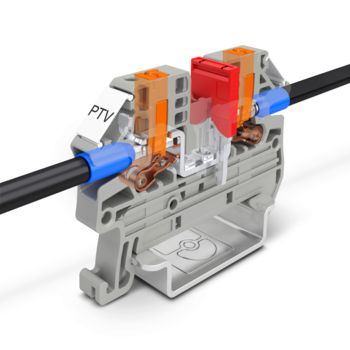

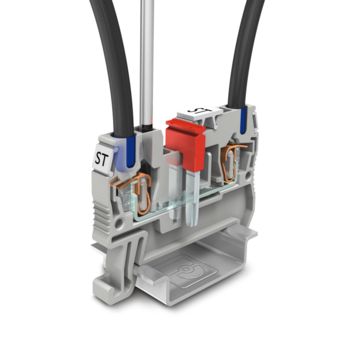

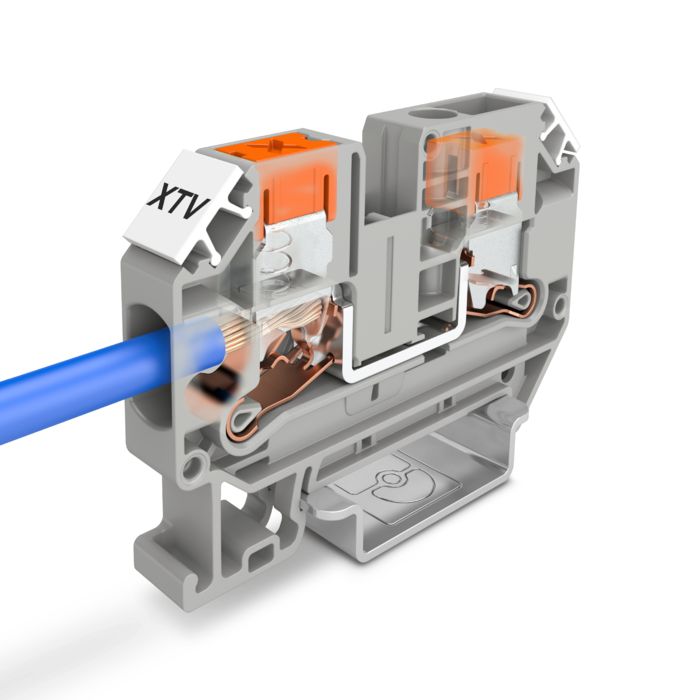

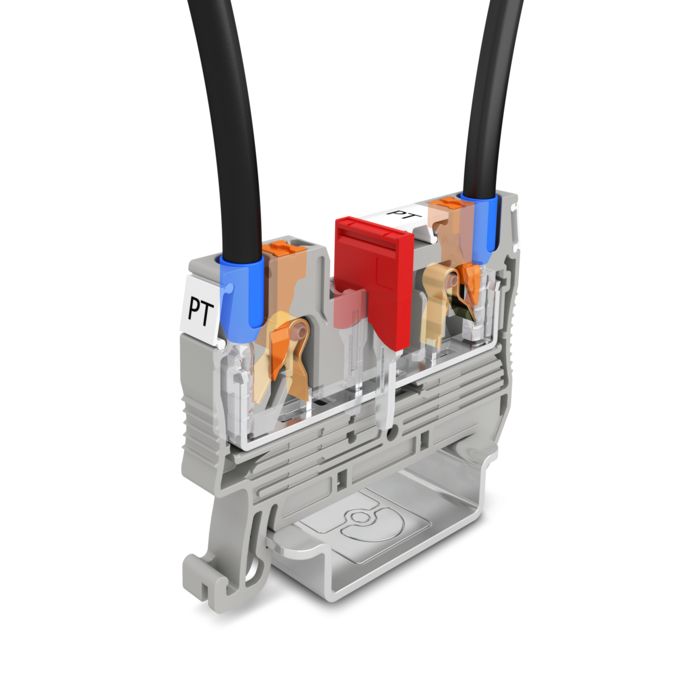

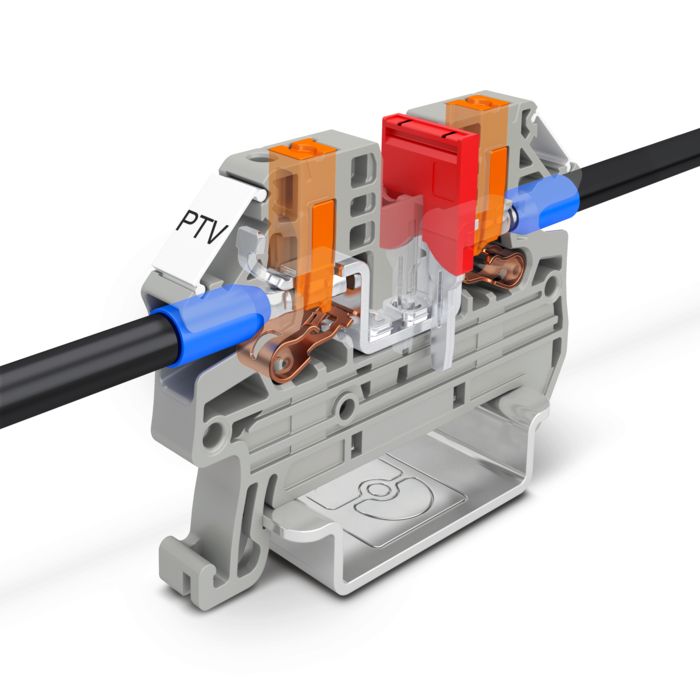

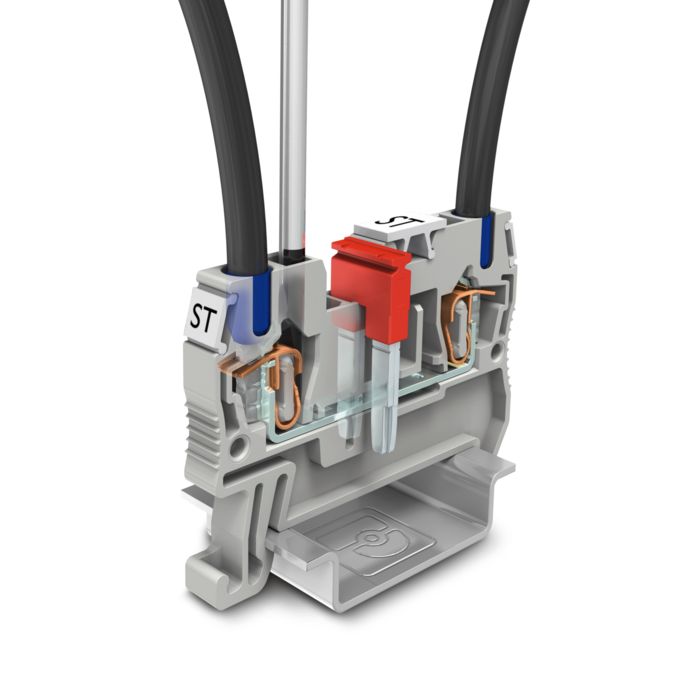

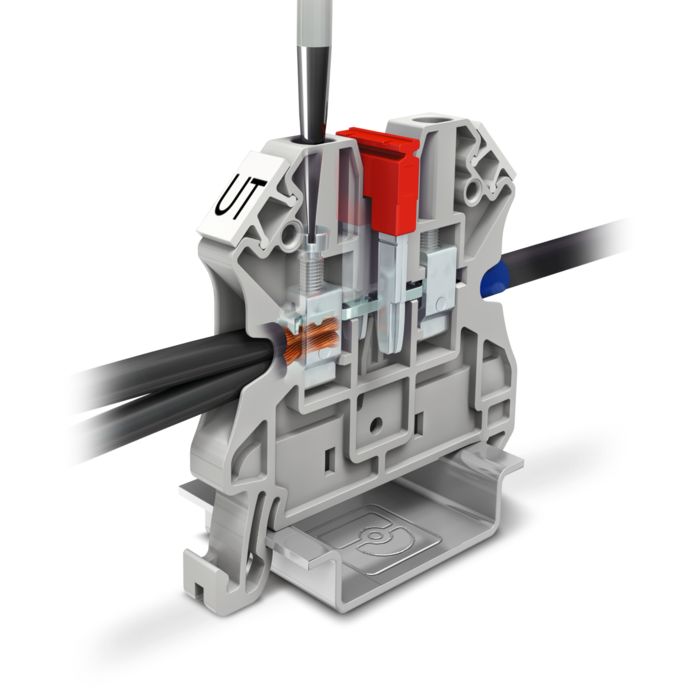

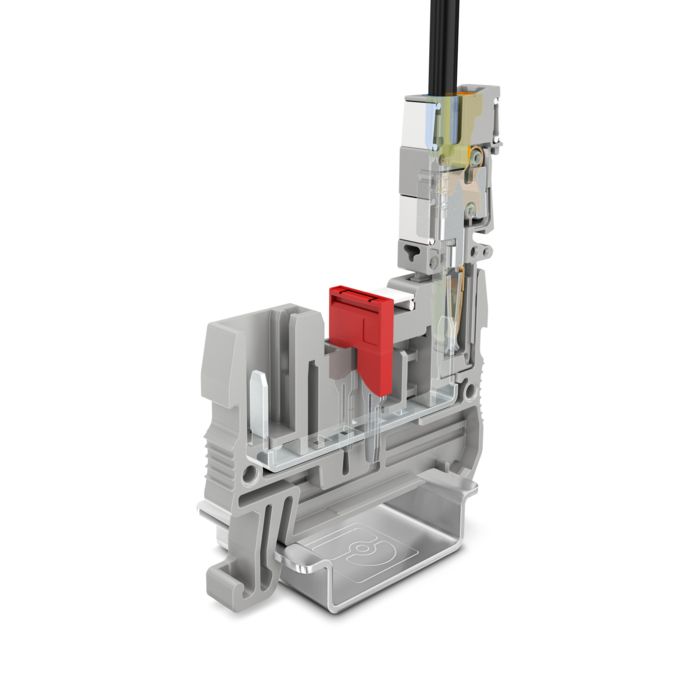

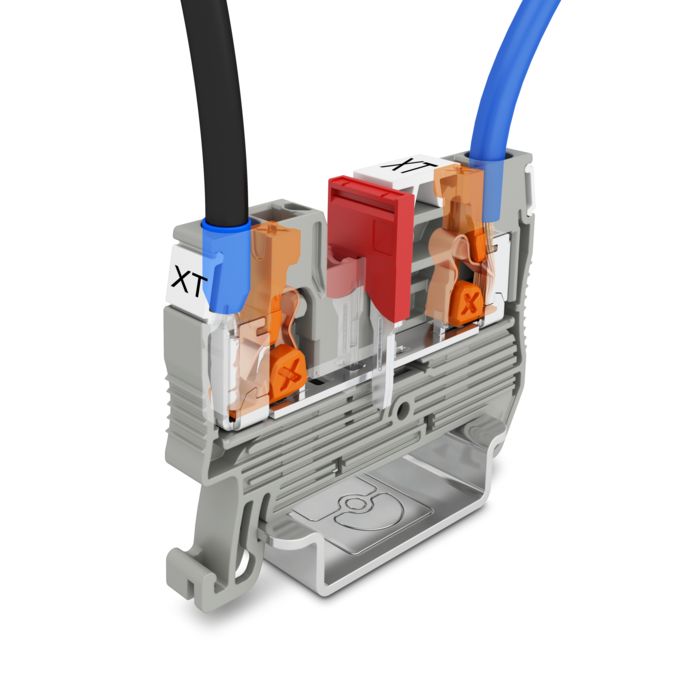

The XT terminal blocks with Push-X technology enable easy connection of rigid and flexible conductors with or without ferrules. Even small and flexible conductors can be clamped quickly and easily with the pretensioned contact chamber. Simply insert the conductors to the end of the chamber. Pressing down the locking mechanism at the end of the chamber releases the contact spring and snaps it shut rapidly. The XT terminal blocks are initially available with a nominal cross-section of 2.5 mm².