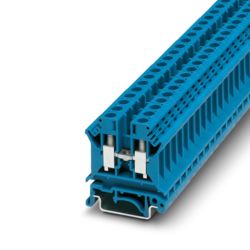

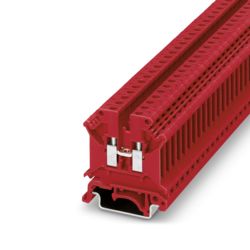

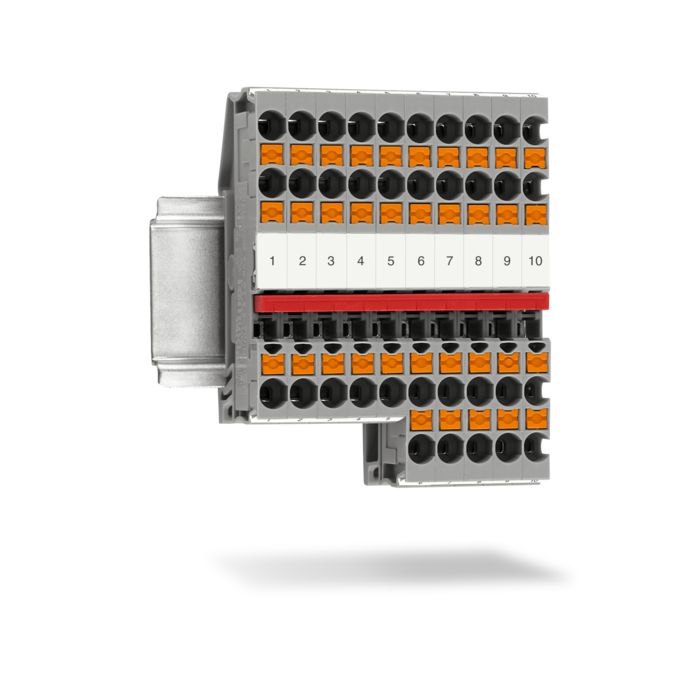

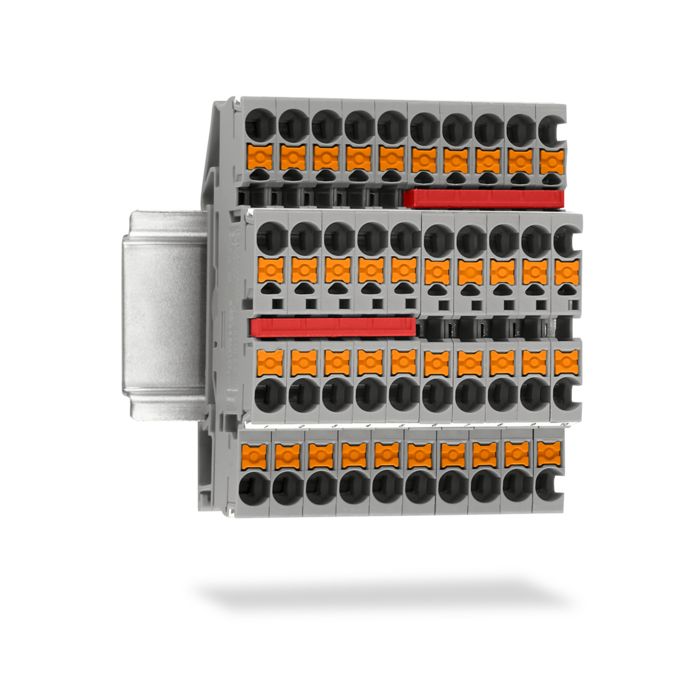

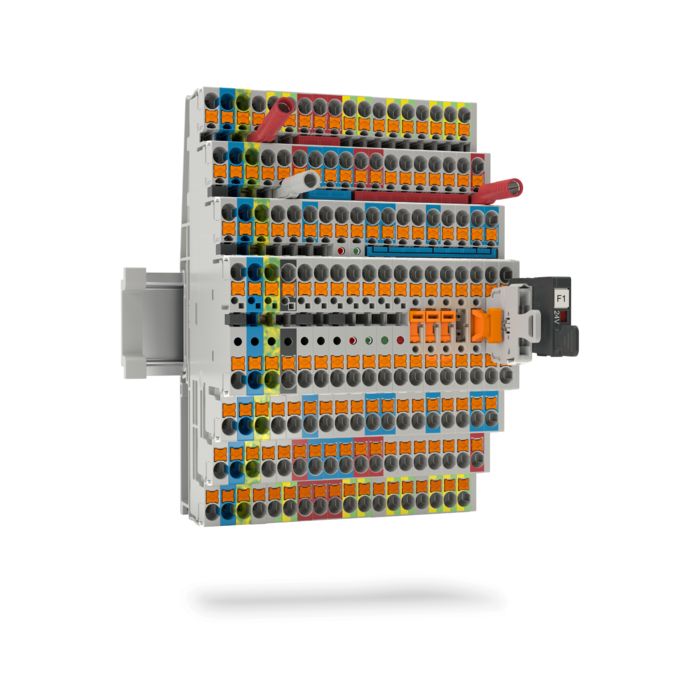

Feed-through terminal block, nom. voltage: 800 V, nominal current: 32 A, number of connections: 2, connection method: Screw connection, Rated cross section: 4 mm2, cross section: 0.2 mm2 - 6 mm2, mounting type: NS 35/7,5, NS 35/15, NS 32, color: orange