Secure teleservice solution minimizes downtimes of rotary transfer machines

-

When it comes to ensuring smooth production processes with high availability, 24-hour service from the machine builder is essential

-

Secure remote access to the system installed at the end user’s premises is a fundamental aspect of the service concept

-

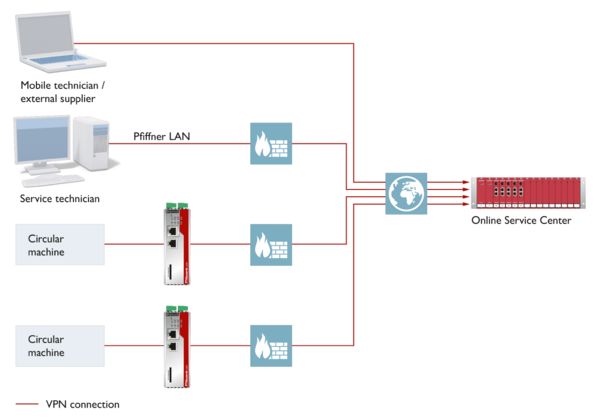

The FL mGuard RS4000 TX/TX VPN security router from Phoenix Contact acts as the core element of the new remote maintenance concept in Pfiffner’s machining centers.

Rotary transfer machines developed by K.R. Pfiffner GmbH

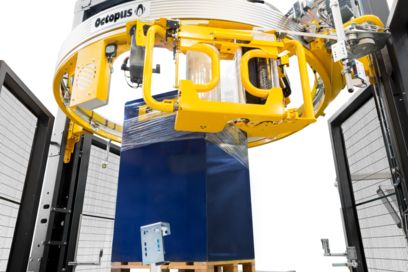

Rotary transfer machine from Pfiffner for mass production of precision parts

The rotary transfer machines developed by K.R. Pfiffner GmbH produce more than 300,000 workpieces each year, the largest of which can be the size of a fist.

The machining centers, which are used for mass production of precision parts for the automotive industry, for example, are manufactured by 450 people around the world.

Secure remote access is a fundamental aspect of the service concept

To ensure smooth production processes with high availability, 24-hour service from the machine builder is essential. This is the only way to ensure that the relevant measures are taken in the event of an error so that the machining centers are only out of action for a short period of time. Secure remote access to the system installed at the end user’s premises is a fundamental aspect of the service concept.

“Initially, remote maintenance was carried out using analog modem connections. However, their performance no longer satisfied our requirements. We also experienced frequent connection problems,” states Tobias Halbritter, who supervises the remote maintenance system at Pfiffner and is largely responsible for the implemented structure based on secure VPN (Virtual Private Network) connections.

As we were already using the mGuard technology with built-in firewall to connect our systems to the customer network, we are now also using the device for secure remote access.

The FL mGuard security router is the core element of the new remote maintenance concept

The FL mGuard RS4000 TX/TX VPN security router from Phoenix Contact, which is installed in the machining centers, acts as the core element of the new remote maintenance concept. For service technicians, the VPN connection makes it seem almost as if they are sitting directly in front of the system. This shortens maintenance response times. Moreover, on-site call-outs are no longer necessary for the most part, resulting in significant savings in maintenance costs.

The user initiates the establishment of the IPsec tunnel to the Pfiffner Remote Services Center by actuating a key switch. Maintenance personnel then have access to the system. The system operator thus maintains control over any access to the application. FL mGuard’s optional external configuration memory is also helpful in this regard. Since Pfiffner employees often do not know the IP parameters of the customer network before machine delivery, the respective configuration can simply be transmitted via SD card later.

The VPN hub is deliberately not integrated into the Pfiffner corporate network, but is operated as a portal system with its own Internet access. This means that Pfiffner can also provide external suppliers with secure access to parts of the relevant customer system without tunneling them through their own communication network.