Industrial Bluetooth for high-performance packaging machines Bluetooth wireless systems ensure reliable communication in machine building.

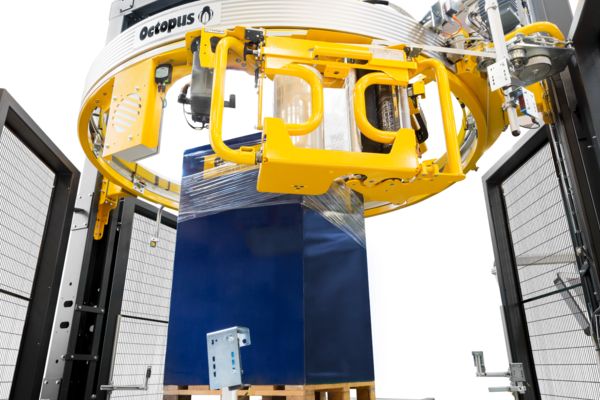

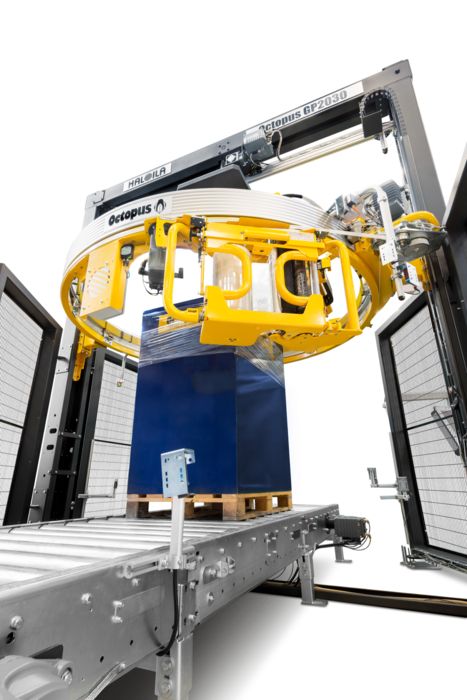

- Modular pallet wrapping machine is the first packaging machine in the world to have a rotating ring construction

- Bluetooth wireless systems are a reliable and wear-free solution for communication between the central controller and rotating machine parts

Modular pallet wrapping machine

Oy M. Haloila Ab is a world-leading manufacturer of pallet wrapping machines and is part of the international Signode Industrial Group. The most well-known brand from the Finnish company is the “Octopus” packaging machine.

This modular pallet wrapping machine is the first packaging machine in the world to have a rotating ring construction for flexible adaptation to customer requirements with regard to production capacity, transport protection, and stability.

Packing of pallets in the wrapping machine

The previous layout of the Octopus machines severely restricted data transmission between the actuating drives of the control system and the actuating drives in the moving parts. The wireless solution has opened up more options and increased reliability. We are extremely happy, both with the products and with Phoenix Contact’s commitment and support.

Bluetooth EPA modules used for reliable and wear-free communication

In place of a collector wire, an Industrial Bluetooth communication solution from Phoenix Contact is used to guarantee reliable, wear-free communication between the central controller and moving machine parts. The Bluetooth EPA modules have been specially developed for the communication of frame data. The robust modules feature protection class IP65 and are suitable for use in harsh industrial environments. Equipped with a special integrated antenna, the system also wirelessly transmits automation protocols such as PROFINET and EtherNet/IP™ easily and reliably.

Bluetooth is the chosen wireless technology in this case, as the frequency hopping method and WLAN channel blacklisting guarantee fault-free parallel operation with the existing WLAN networks in the 2.4 GHz frequency band.