IoT-based energy management in manufacturing

Improving energy efficiency is a team effort. However, to be able to involve and inspire all concerned parties to a reasonable extent, energy consumption must be presented in a clear and comprehensible manner. The IoT-capable EMpro energy measuring devices and the intuitive, flexible functions of the IoT-based service Energy Management Service – Powered by Proficloud.io help with simple, cloud-based data collection and targeted, meaningful visualization.

The challenge

Transparency of energy data for deriving measures

Energy consumption per assembly group should be made more visible both during active production times and in standby times, after the end of production or on weekends.

Energy consumption at active and passive times

- Comparison of energy consumption in active and passive times

- Determination of the proportional energy consumption during the passive time

Energy consumption at different assembly times

- Comparison of the energy consumption of an assembly group at various assembly times in connection with the respective production figures

Energy consumption per manufactured piece

- Comparison of the number of pieces produced with the energy consumed (kWh)

- Energy consumption per manufactured piece (carbon emissions per piece)

Optimize power-on management

- Identify peak loads

- Derive measures to optimize power-on management

Our solution

IoT-capable energy measuring devices deliver data automatically directly to Proficloud.io

Directly to the cloud with Iot-capable EMpro energy measuring devices Automated data transfer to Proficloud.io

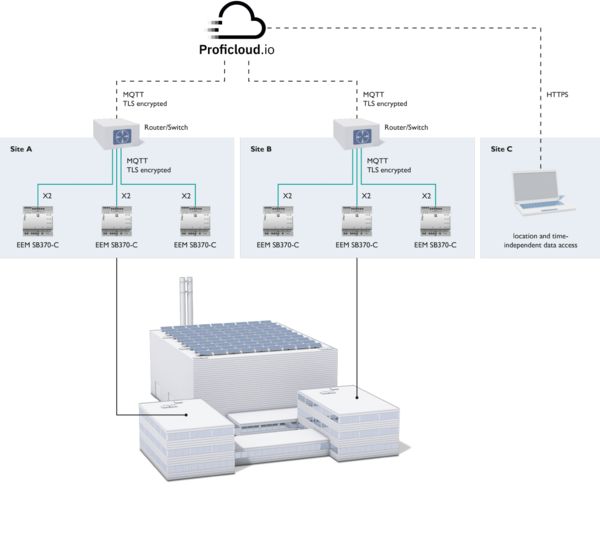

In order to be able to display the energy consumption of various assembly groups more transparently, Phoenix Contact has equipped a production area at its Blomberg location with IoT-capable EMpro energy measuring devices. The energy measuring devices are connected directly to the IoT cloud environment via plug-and-play via the Ethernet interface and transmit the measured data automatically to Proficloud.io from Phoenix Contact.

There are various assembly groups in a production area. Each group, in turn, has several production facilities. In total, 72 devices were installed.

The benefits of IoT-based energy management

- Easy and fast retrofitting of energy measuring technology using IoT-capable EMpro energy measuring devices, which can be connected directly to the IoT cloud environment via Ethernet interface through a plug-and-play principle

- Energy managers can collect energy data with little effort and immediately visualize it graphically, without programming or necessary expertise

- Tracking of energy data and key figures offers the opportunity to make production more efficient

- Continuous improvement process through full transparency of energy data and thus uncovered efficiency potential

Automated data transfer to Proficloud.io Basic image of the system topology

Example of an application for IoT-based energy management

The Energy Management Service – Powered by Proficloud.io

The Energy Management Service – Powered by Proficloud.io places specialists in energy management as the users right at the center and is tailored precisely to their needs. With a simple, intuitive design, the service provides a flexible spectrum of functions in the field of electrical energy and power data visualization for monitoring, analyzing, and evaluating this data.

The Energy Management Service – Powered by Proficloud.io thus supports energy managers proportionally in the check step of the PDCA cycle (Plan, Do, Check, Act) in accordance with the international standard ISO 50001:2018 (Energy management systems – Requirements with guidance for use).

Summary

Systemic, comprehensive package for future-oriented energy management

Together with the IoT-capable EMpro energy measuring devices, the Energy Management Service – Powered by Proficloud.io offers an overall system package for digitalized energy management.

The system combines the benefits of the Industrial Internet of Things, sophisticated measurement technology, and constantly evolving smart services.

Automated data transfer to Proficloud.io, a high degree of user-friendliness and intuitive menu navigation make the work of energy management managers very efficient. Purpose-built visualizations provide a targeted overview.