IoT-based energy management

IoT-based energy management combines the benefits of the Industrial Internet of Things, sophisticated measurement technology, and constantly evolving smart services. For example, energy management managers benefit from the easy availability of measurement data, automated data storage, and the ability to access energy and power data anywhere and at any time.

Challenges

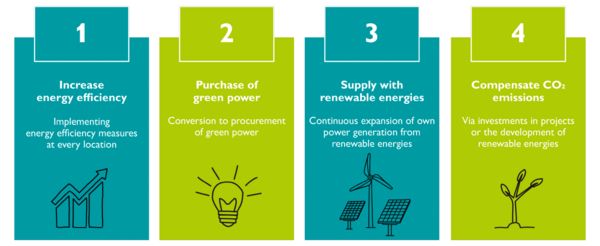

Energy management and climate protection

In a time of scarce resources, rising energy prices, and the importance of climate protection, comprehensive energy management is one of the central issues for today’s companies.

The need to reduce carbon emissions, create transparency about the production process, and evaluate the specific carbon footprint of a manufactured product poses new challenges for those responsible for energy management.

In order to derive the right energy efficiency measures from this situation, energy data must be collected, monitored, analyzed, and evaluated. Precisely tailored and easy-to-integrate energy monitoring forms the basis for meeting the requirements of the energy management standard ISO 50001.

Reference to ISO 50001 and possible questions from customers

The international standard ISO 50001:2018 (DIN EN ISO 50001:2018) is a guide for companies and supports them in implementing an energy management system. The standard describes the energy management system as a systematic approach to improving energy-related performance and can mean additional cost benefits for certified companies.

To evaluate the success of implemented energy efficiency measures and continuously monitor processes, energy management managers need to define the right key performance indicators (KPIs) or energy performance indicators (EnPIs).

In the context of management reviews or internal and external audits, these key figures provide an indication of how well energy management is functioning and whether government and/or normative requirements are being met.

The challenge of data acquisition and analysis How do energy management managers work today?

Energy management managers must always have an overview of processes and resource consumption within their company. The measurement data relevant for this is partly collected manually from distributed data sources (energy measuring devices) and imported, e.g., via CSV files, into energy data collection systems.

Analysis and evaluation is often carried out using self-created MS Excel spreadsheets, from which the necessary diagrams are subsequently created. Additional software tools that prepare the data graphically are also used.

Typical topologies today include a large number of measurement points that must be networked together. Standard systems can often only be installed or extended with considerable effort and extensive expertise in complex networks. This requires trained personnel and can result in high system maintenance costs.

What is the right system of software and hardware to record and process the required measured variables? And what IT infrastructure is needed for this?

IoT-based energy management

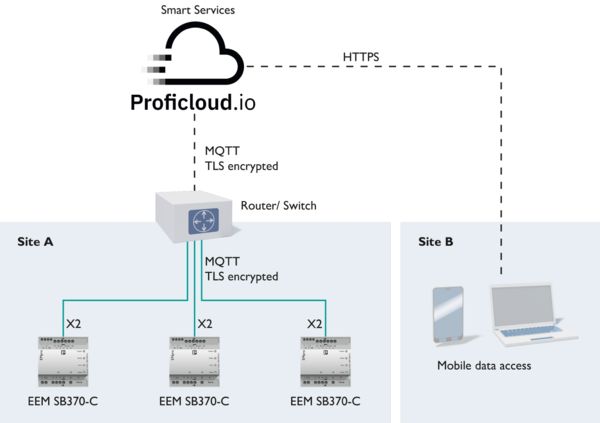

Cloud-based data acquisition

IoT-capable measuring devices (smart devices) are connected directly to a cloud platform via an Ethernet interface and the MQTT protocol using plug-and-play. Within the cloud environment, the measuring devices can be quickly and easily integrated into a new or existing system via the Device Management Service. The selected measured values are automatically transferred and stored. Energy management managers have immediate access to this data via the smart service and can use it directly. Complex configurations of classic industrial networks (e.g., Modbus or PROFINET) are now a thing of the past.

Topology of IoT-based energy management

Advantages of IoT-based energy management

- Fast availability of measurement data, without special knowledge of complex networks, through simple plug-and-play integration of IoT-capable measuring devices in the cloud system

- No need to maintain in-house IT resources or have extensive IT knowledge due to automated data storage directly in Proficloud.io

- Generate cross-site reports faster with the ability to access energy and power data anywhere and at any time

- Data security is always up to date through regular, automated security updates

- Access to new functions is always fast and up to date with the dynamic release cycles of the IoT platform (cloud environment) and smart services

Smart services

Energy Management Service – Powered by Proficloud.io

Energy Monitoring, Management, Analytics: the smart Energy Management Service – Powered by Proficloud.io focuses on energy management managers as the users and is precisely tailored to their needs. With a simple, intuitive design, the service provides a flexible spectrum of functions in the field of electrical energy and power data visualization for monitoring, analyzing, and evaluating this data.

The Energy Management Service – Powered by Proficloud.io thus supports energy management managers proportionally in the check step of the PDCA (Plan, Do, Check, Act) cycle in accordance with the international standard ISO 50001:2018 (Energy management systems – Requirements with guidance for use).

Your advantages

- High-level user-friendliness with a systemic overall concept with intuitive menu navigation and automated data transfer to Proficloud.io

- Targeted overview of energy and power data anywhere and at any time with purpose-oriented visualizations

- Constantly increasing value benefits for your energy management with continuous, user-oriented further development

- Secure communication between the device and cloud via TLS encryption

- Device management for a clear overview of the applications