Are your safety circuits NFPA 79 compliant?

In the United States the National Fire Protection Association (NFPA) 79: Electrical Standard for Industrial Machinery is a complementary document of the National Electrical Code (NEC) that outlines requirements for the protection of operators, equipment, facilities, and work-in-progress. NFPA 79 requires Listed surge protection to protect these vital applications.

The UL Listed VAL-US surge protection product line from Phoenix Contact ensures compliance to these requirements. Learn more about where to install surge protection in your application to protect your safety circuits in our NFPA 79 Design Guide.

Advantages

- All UL 1449 Type 1 Listed VAL-US products fully comply with the requirements of NFPA 79

- UL Type 1 Listing of the VAL-US products ensures quick and easy inspection approval

- With a 200 kA SCCR rating, VAL-US products can be applied virtually anywhere within the electrical system

- Application of the VAL-US products is simplified with product descriptions to easily identify system voltages and configurations

- Further enhance the safety of your systems with local and remote status monitoring of the VAL-US products

What does the NFPA 79 standard regulate?

The NFPA 79 Electrical Standard for Industrial Machinery is a USA standard that defines safety requirements for industrial machinery used in the USA. It regulates electrical and electronic concepts regarding overcurrent protection, cabling, safety circuits, and surge protection in its latest edition.

The NFPA 79 is revised every two to five years, and NFPA 70 (NEC) is updated every three years.

Why does my machine have to comply with NFPA 79?

Every machine that is commissioned must first be inspected and approved by a qualified inspector. This inspection is based on the NFPA 79 Standard, along with the National Electrical Code (NEC – NFPA 70).

Where is the directive applicable and what is its scope?

This directive applies to all industrial machines utilized in the USA. The applicable edition of the NFPA 79 Standard varies from state to state and is dependent upon the edition of the National Electrical Code that the specific state/area officially recognizes.

How are the various rule and content differences in the revised Standards being implemented?

Along with the NEC and the NFPA 79 Standards, control cabinets that are installed within industrial machines must also comply with UL 508A. If there are varying demands or overlaps in the requirements called for by these three Standards, the strictest demand among them applies. When recommending overcurrent protection equipment, for example, the lowest value protection requirement that is stated by any of the three Standards must be observed.

Why is surge protection mandatory with the new edition of the NFPA 79?

Protection of personnel is a guiding principle of NFPA 79. As such, surge voltages must be suppressed to preclude damage to the safety systems of a machine.

How do I satisfy the demands of NFPA 79 in terms of surge protection?

Power supplies for industrial machines that are equipped with safety circuits, per NEC and NFPA 79, must be fitted with surge protective devices (SPDs). These SPDs must be “UL 1449 Listed” products that feature a short-circuit current ratings (SCCR) that are greater than the short-circuit current availability at the SPD’s installation location within the electrical distribution.

How are surge protective devices installed so that they satisfy the requirements called for by the NFPA 79 Standard?

Surge protective devices for the power supply are to be installed as close to the power input point as possible. Depending on the location of the machine in the installation, the appropriate SPD types (see NFPA 79, Article 7.8) are to be selected. The VAL-US series makes this particularly easy since, as UL Type 1 Listed devices, they can be deployed anywhere within the electrical distribution.

While surge protective devices for signal and data technology are not required by the NFPA 79 Standard, they are typically recommended to protect the machines’ data communication interfaces.

Where can I find comprehensive information in the NFPA 79?

The NEC and NFPA 79 standards can both be viewed free of charge, or they can be purchased in either electronic or print formats from the National Fire Protection Association's website.

USA power distribution configurations

Electrical distribution configurations, voltages, and power transmission frequencies in the USA are different than those found in most parts of the rest of the world. While most industrial machines are operated on "3-phase WYE" or "DELTA” configured electrical services domestically, other common electrical system configurations utilized in North America include:

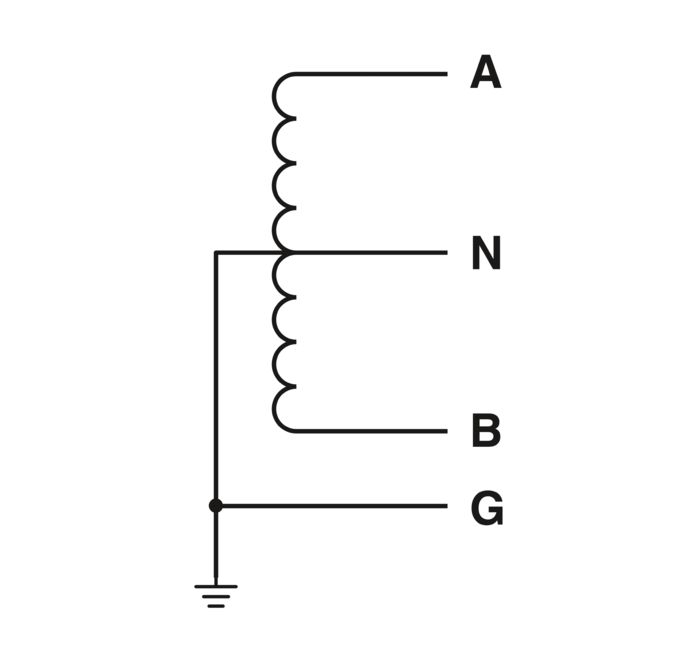

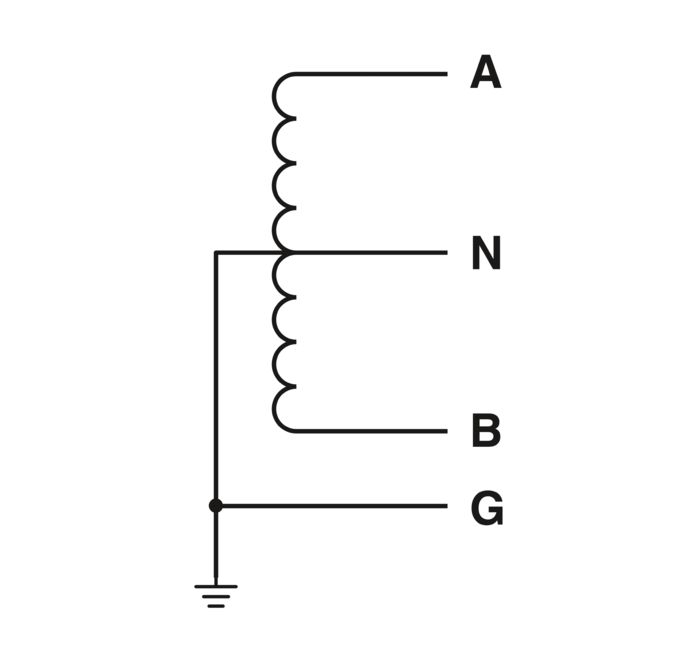

Split-phase

This voltage configuration is largely unknown outside of the USA today. It is created via a secondary-side center tap connection on a single-phase transformer. The center tap connection is grounded and designated as a Neutral conductor that serves as the common return for both the Phase conductors. The nominal voltage between either Phase conductor and the Neutral is exactly half the voltage value between the two Phases. The configured voltage values are 120 / 240 V, with 240 VAC measured between Phases and 120 VAC measured between either Phase and the Neutral.

This service configuration is used in almost all households and small office buildings in the USA. Small and low-power equipment including computers, televisions, and lighting circuits are connected to the 120 V circuit(s). Air conditioning systems, hot tubs, electric ranges, and electric dryers are connected to the 240 V circuit(s).

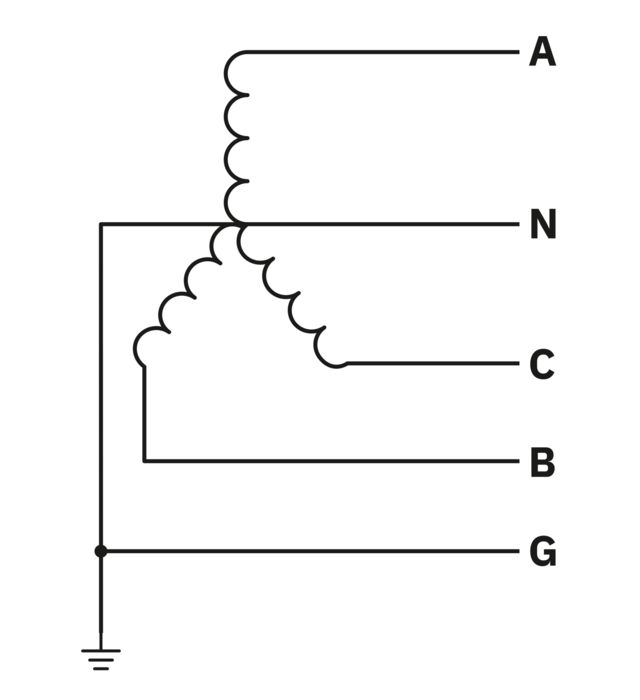

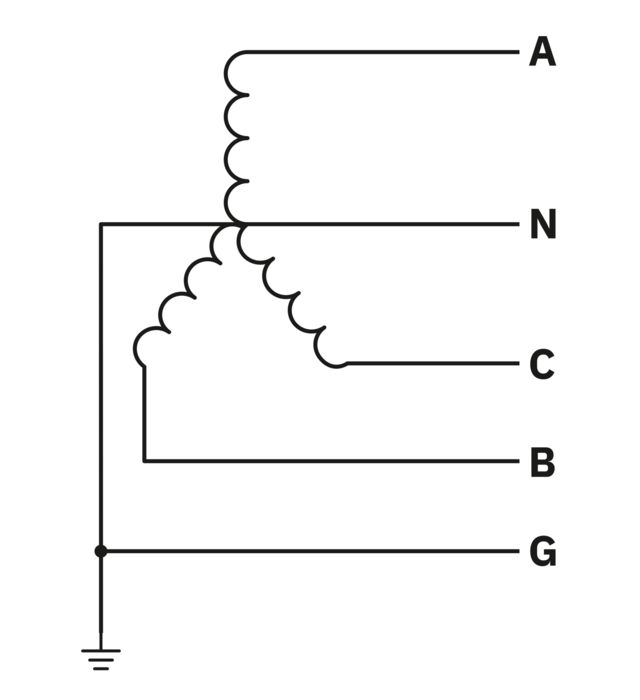

3-Phase WYE

This distribution voltage configuration is like the TN grid system used in Europe but is designed using different voltage values. The distribution’s 3-Phase conductors are fed from a transformer configured with a star (WYE) topology, and are phase shifted by 120° between each other. The Neutral point is grounded. Depending on AC powering requirements, the Neutral conductor may or may not be connected to the equipment loads. The nominal voltage values of these distributions are typically configured as either 120 / 208 V or 277 / 480 V in the USA.

127/220 V, 3-Phase WYE configured electrical distributions are also available in Mexico, as are 347 / 600 V, 3-Phase WYE configured services in Canada.

These voltage configurations are typically used in industrial applications that have higher power demands than residential electrical consumers.

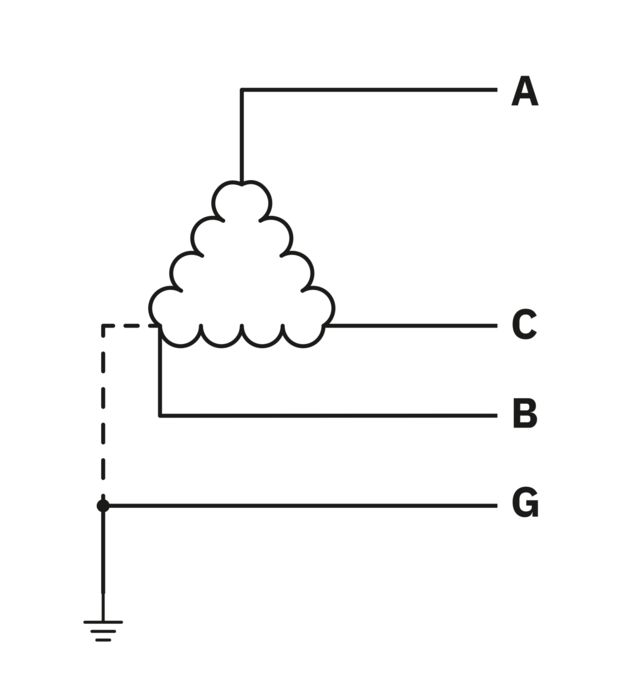

Corner-grounded / Ungrounded DELTA

Corner-grounded / Ungrounded DELTA

This configuration is rarely seen outside of North America. The feeding transformer is configured with a DELTA topology on its secondary side. A Neutral conductor is not utilized. The voltages used are 480 V in the USA and Mexico, and 480 or 600 V in Canada.

Depending on the grounding system, there are two different versions:

Ungrounded DELTA: The transformer is not grounded on the secondary side. This system behaves similarly to an IT configured system used in Europe.

Corner-grounded DELTA: One phase conductor is directly Grounded. Corner Grounded power distributions are usually found in older installations.

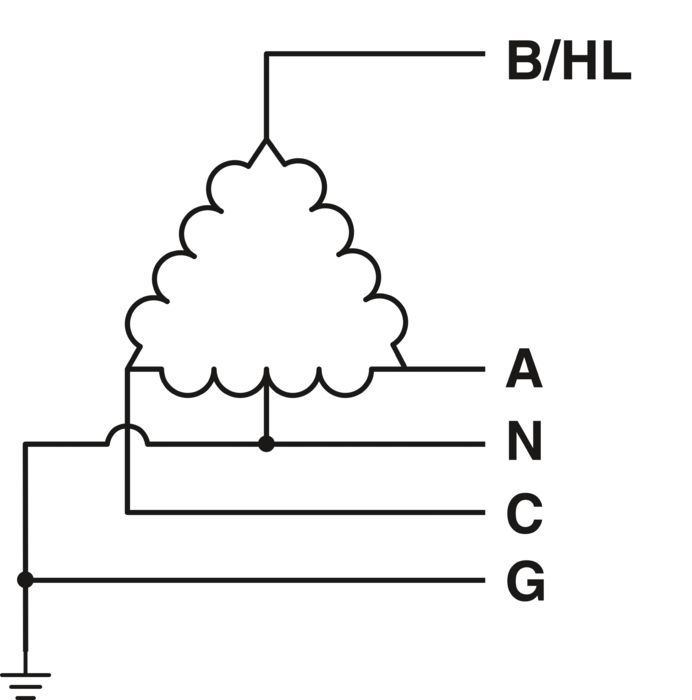

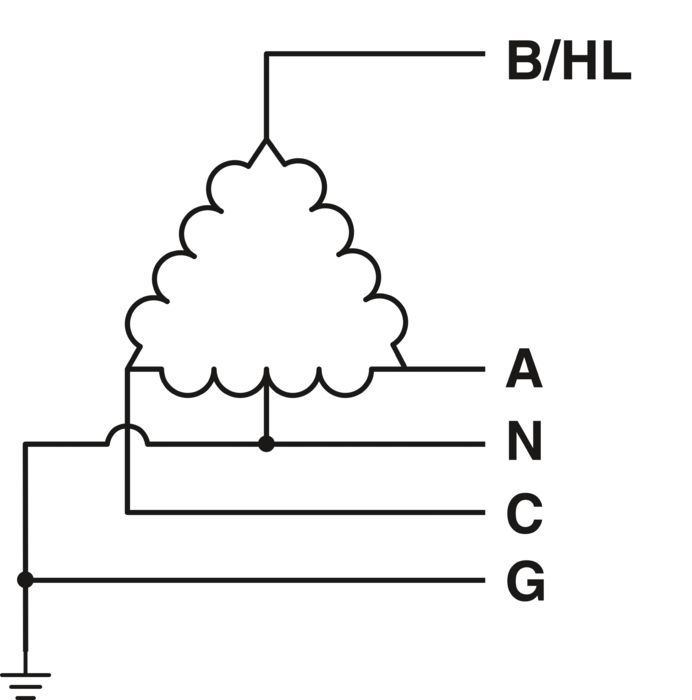

High-leg DELTA

This configuration is not used in Europe. It is a DELTA / split-phase hybrid configured electrical service. The DELTA system’s nominal voltage values are 240 VAC between any two Phase conductors. But, with a high-leg DELTA configured distribution one of the three legs also has a grounded center tap connection. As a result, there are three voltages:

Phase A – N = Phase C – N = 120 V

Phase B – N = 120 V * √3 = 208 V

Between any two Phases = 240 V

This power distribution configuration is used in large office buildings and small industrial facilities. As with the Split-phase configured electrical services, low-power equipment loads are connected to the 120 V circuits, and higher-powered devices are connected to the 240 V circuits. The 208 V circuit is not typically used.

SPD types in accordance with UL 1449

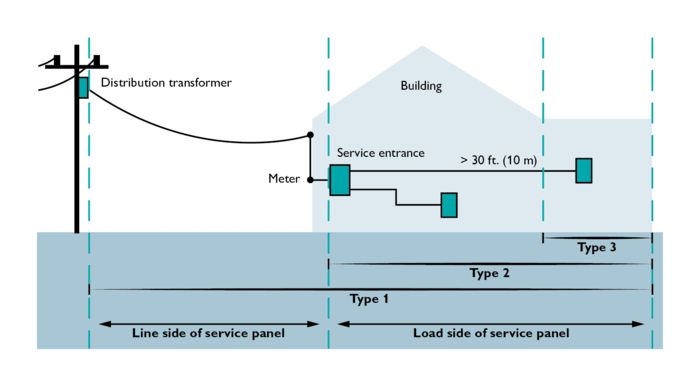

Surge protective devices (SPDs) are categorized as various types of protectors that indicate where within an electrical distribution they can be installed. However, that categorization does not address their performance characteristics or their areas of application with reference to a lightning protection concept.

Type 1 SPDs Type 1 SPDs may be installed downstream of a transformer and upstream of the main overcurrent protection of the power system. Type 1 SPDs may also be installed in Type 2 or 3 locations as well.

Type 2 SPDs

Type 2 SPDs must be installed downstream of the main overcurrent protection of the power system. Type 2 SPDs may also be installed in Type 3 locations.

Type 3 SPDs

Type 3 SPDs must be installed a minimum of 30ft (~10m) downstream of the main overcurrent protection of the power system.

Product Requirements

While VAL-US products were designed to protect North American power distributions, they include models that are intended to protect European voltage configurations as well.

VAL-US products are UL Listed, therefore they satisfy the requirements of NFPA 79. Because they have a 200 kA SCCR, they can be used universally throughout North America, as well as almost anywhere on Earth.

Split-phase voltage options

120 / 240 V AC (A ,B, N, G) VAL-US-120/40/2+1-FM (2910352)

3-phase WYE Configured System Voltage Options

120 / 208 V AC (A, B, C, N, G) VAL-US-120/40/3+1-FM (2910354)

120 / 208 V AC (A, B, C, G) VAL-US-120/40/3+0-FM (2910353)

277 / 480 V AC (A, B, C, N, G) VAL-US-277/40/3+1-FM (2910374)

277 / 480 V AC (A, B, C, G) VAL-US-277/80/3+0-FM (1075896)

347 / 600 V AC (A, B, C, N, G) VAL-US-347/30/3+1-FM (1079099)

347 / 600 V AC (A, B, C, G) VAL-US-347/30/3+0-FM (2910383)

High-leg DELTA system voltage options

240 V AC VAL-US-240HLD/40/3+1-FM (2910371)

Overcurrent Protection

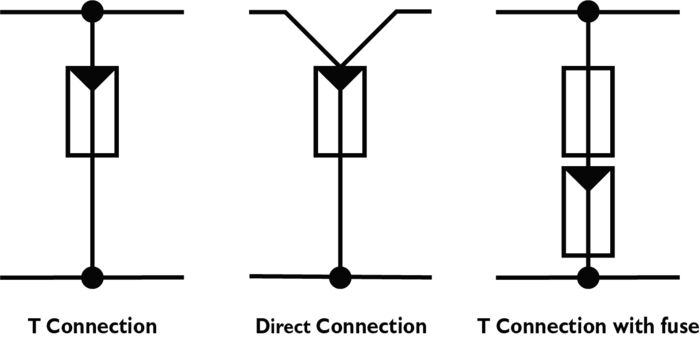

A surge protective device (SPD) that is Listed to ANSI / UL1449 as TYPE 1 devices by a Nationally Recognized Test Laboratory (NRTL) is constructed with an integrated overcurrent disconnecting mechanism. It electrically looks like a “load” to the power distribution as it installs in parallel with the equipment it is intended to protect. Per the National Electrical Code (NEC), it can be installed via a Direct Connection or a T Connection to the AC power distribution without using additional fuses, circuit breakers, or other types overcurrent protectors, as depicted by the illustration to the right.

Parallel connected ANSI / UL1449 defined TYPE 2 and TYPE 3 SPDs are required by the NEC to be installed to the power distribution through an appropriately sized circuit breaker, fuse, or other type of overcurrent protection device in most applications. The illustration to the right portrays a T Connected SPD with fuse configuration where a fuse is installed between the tap point of the power circuit and the SPD.

An ANSI/UL 1449 defined TYPE 1 SPD can also be installed in this same manner if the equipment user requires a disconnecting mechanism to remove power from the SPD for maintenance purposes.

Regarding selecting an appropriate overcurrent protective device (OCPD), the OCPD must be selected based on the wire conductor size per the NEC. It is the responsibility of the system planner, in this case the machine builder, to select the appropriate OCPD. The procedure for designing the OCPD for surge protective devices is the same as for all other devices. However, since an SPD has no load current, the information specified by the SPD manufacturer can be used for the connecting cable. This information includes both maximum and minimum cross sections, as well as the permitted cable material. Based on this information, the surge protective device can then be designed as usual with the aid of the respective NEC tables.

VAL-US surge protection | UL Listed, Open Type 1 SPDs

The new VAL-US surge protection from Phoenix Contact is UL Listed. This Open Type 1 SPD no longer needs to have overcurrent protection in front of it. You simply install this according to your voltage and our instructions.

How to protect safety circuits to meet NFPA 79 (2018)

This video outlines everything you need to know to ensure your safety circuits are protected.