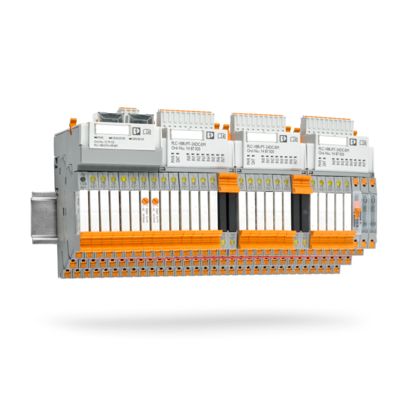

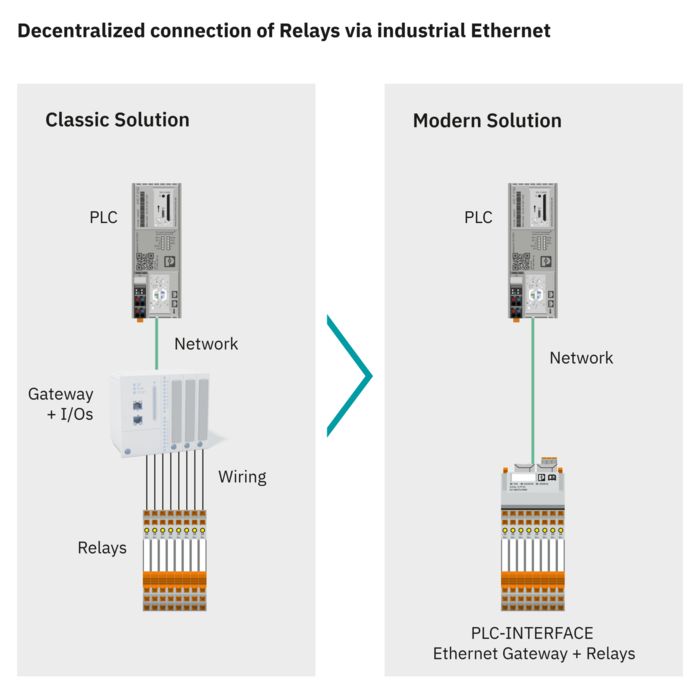

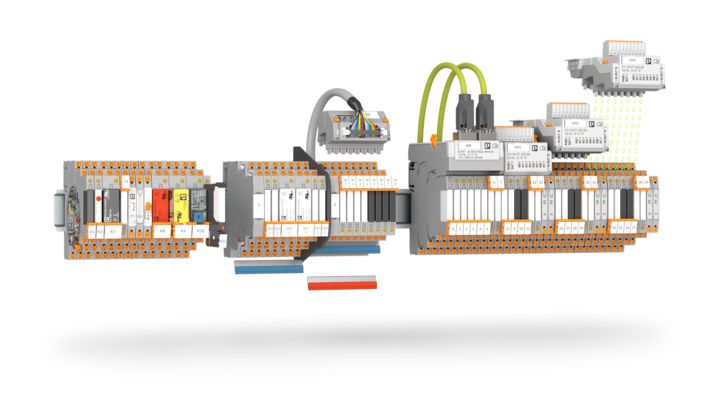

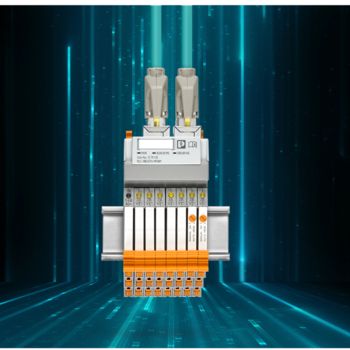

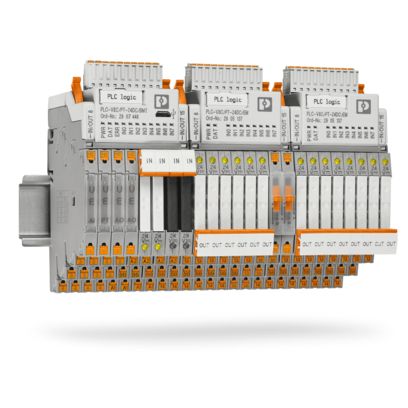

PLC-INTERFACE Ethernet gateway starter kit, consisting of: plug-in base module PLC-V8R/ETH-MP/BM with 2 x RJ45 connection and multi-protocol connection (PROFINET, EtherNet/IP™ and Modbus/TCP), four relay output terminals with Push-in connection and four relay input terminals with Push-in connection.