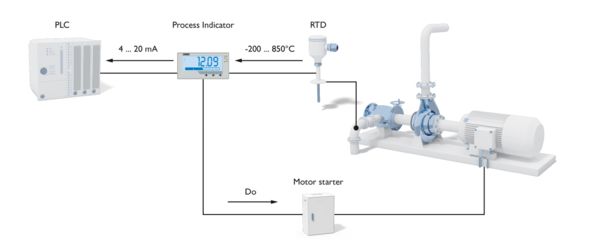

Our multifunctional process displays acquire current, voltage, RTD, TC, and resistance-type sensor signals via the universal input. Current process values are easy to read on the five-digit backlit displays. The bar graph also provides you with a quick overview. Alarm states can be identified easily from a distance because the display changes to red.