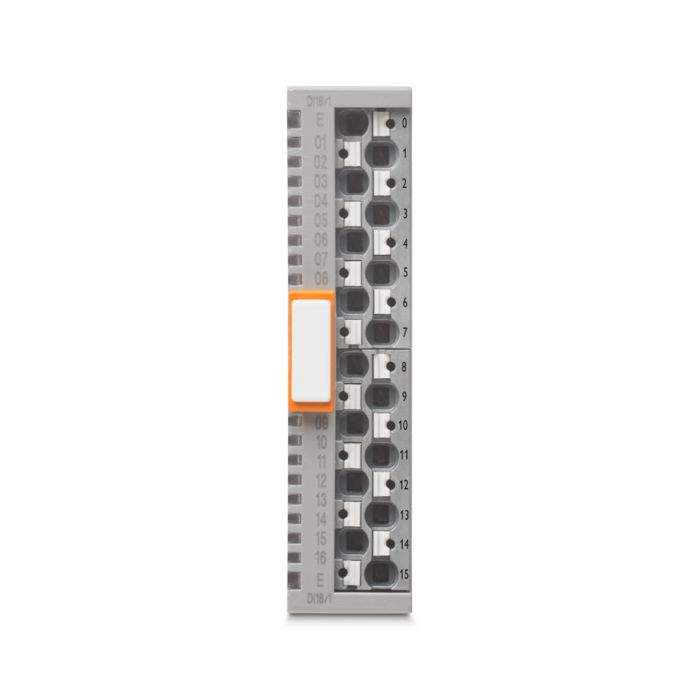

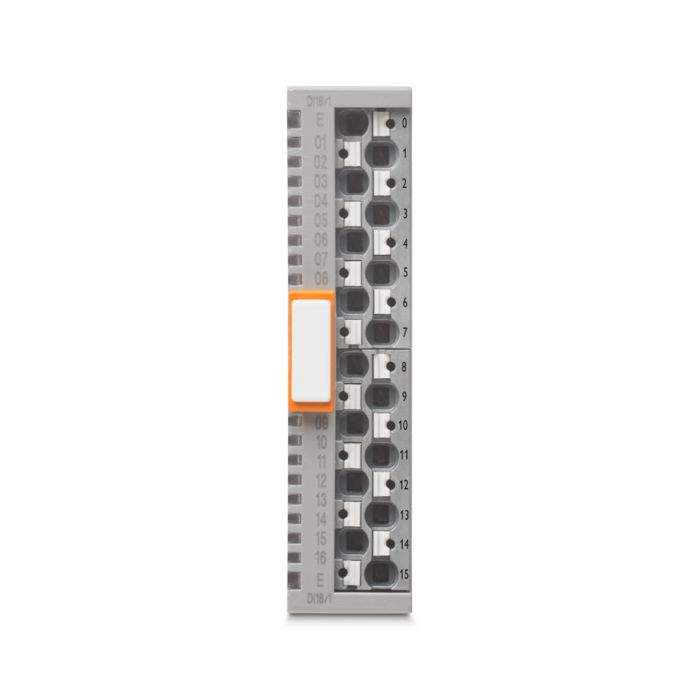

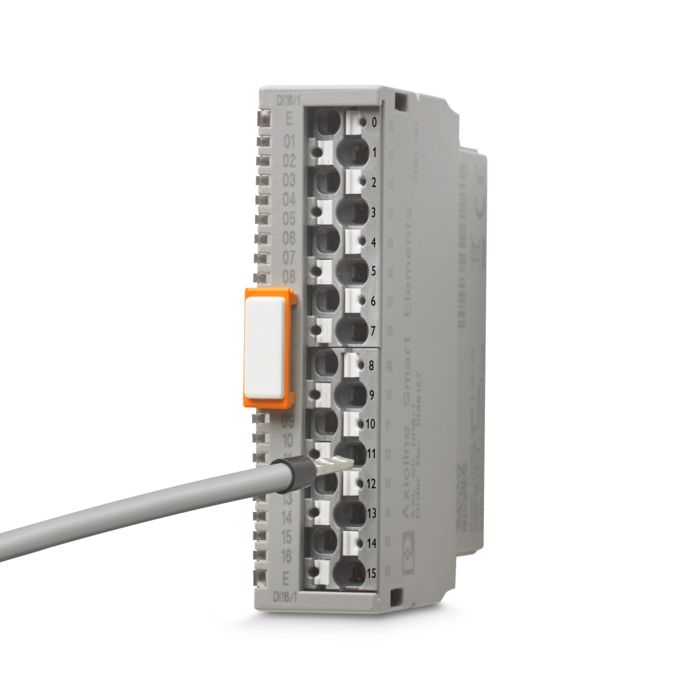

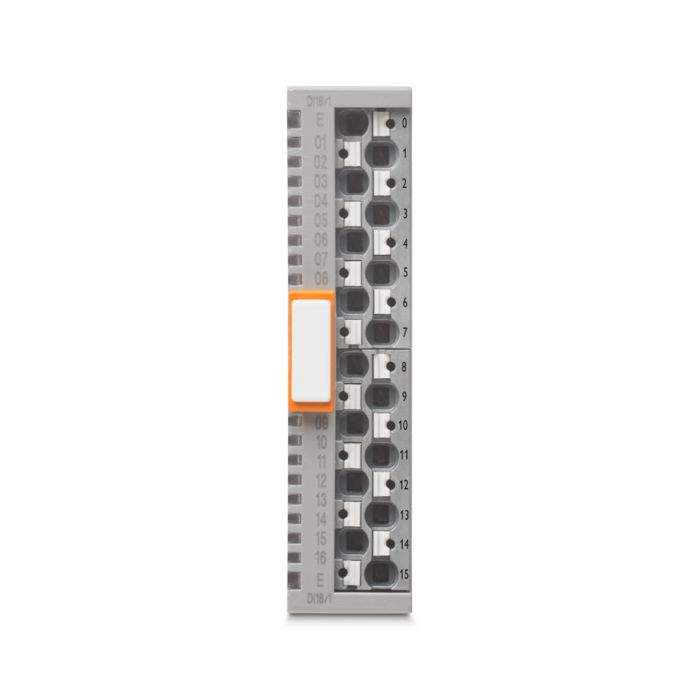

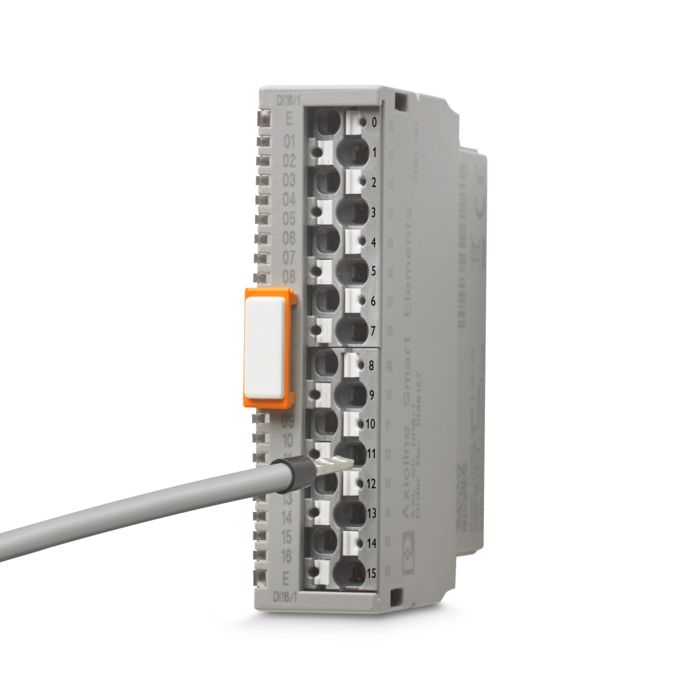

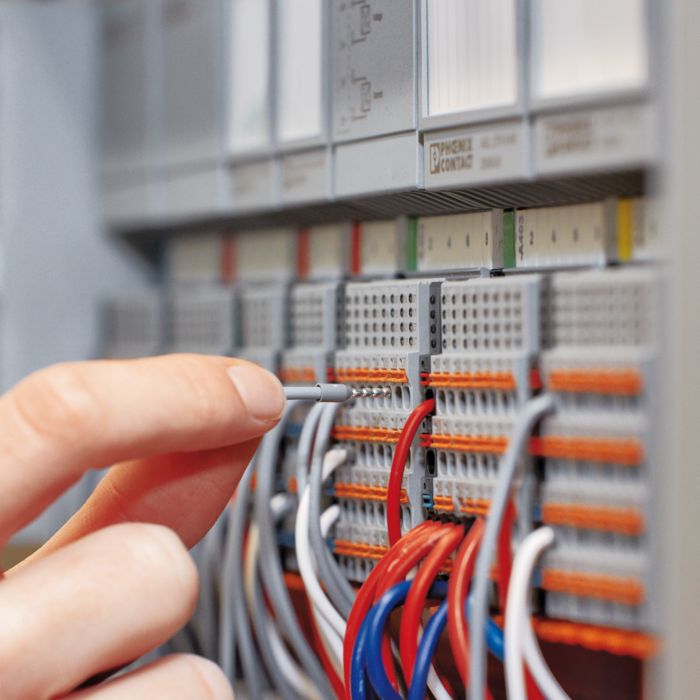

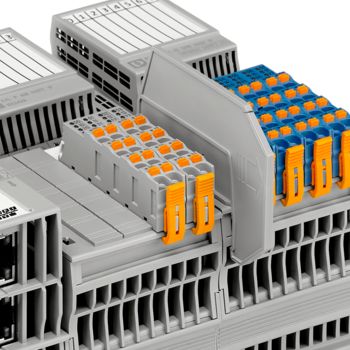

With a footprint of 15 mm x 62 mm, up to 16 connections can be realized on one Axioline Smart element. You can connect conductors with a conductor cross-section of up to 1.5 mm² with ferrules including plastic collars.

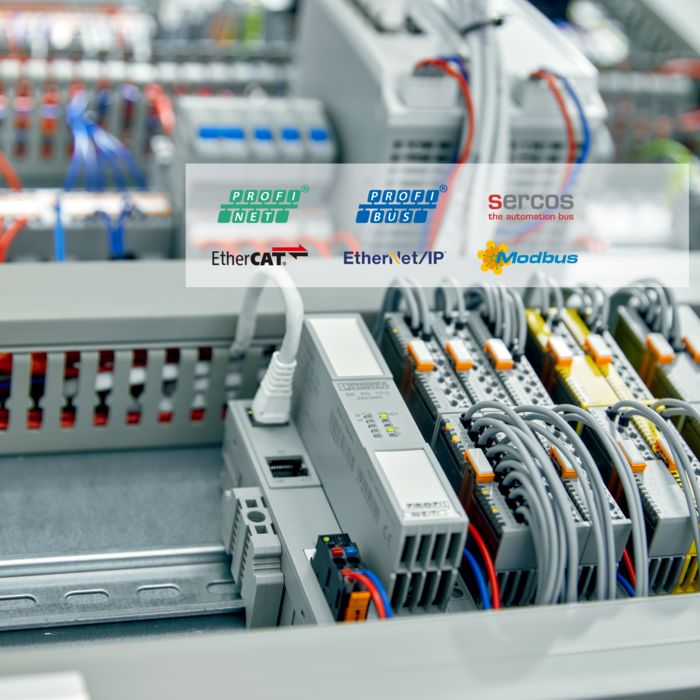

The remote I/O systems from Phoenix Contact with IP20 and IP65/IP67 degrees of protection are suitable for all common bus systems and networks. Acquire input and output signals directly in the control cabinet or in your systems and machines. Your data and signal traffic will be transmitted reliably - optimized for differentiated areas of application. Use products with diverse mechanical properties and functions for this.

Axioline F, Digital I/O module, Digital inputs: 8, 24 V DC, connection technology: 3-conductor, Digital outputs: 8, 24 V DC, 500 mA, connection technology: 3-conductor, transmission speed in the local bus: 100 Mbps, degree of protection: IP20, including bus base module and Axioline F connectors

Inline, Position detection terminal, Incremental encoder input: 1, symmetrical encoders according to EIA-422 and asymmetrical encoders, Digital inputs: 3, 24 V DC, Digital outputs: 1, 0.5 A, transmission speed in the local bus: 500 kbps, degree of protection: IP20, including Inline connectors and marking fields

Inline terminal for power distribution (GND), complete with accessories, (connector and labeling field) connections for GND

Gateway for the connection of up to 32 Interface system devices to a higher-level controller via CANopen®. The Interface system devices are connected to the gateway via DIN rail connectors. The DIN rail connectors are provided.

Axioline Smart Elements, Potential distribution module, 24 V DC, degree of protection: IP20

Inline, Analog input terminal, Analog inputs: 4, 0 V ... 10 V, -10 V ... 10 V, connection technology: 2-conductor, transmission speed in the local bus: 500 kbps, degree of protection: IP20, including Inline connector and labeling field

Inline, Communication terminal, interface RS-485: 1, Communication via process data, transmission speed in the local bus: 500 kbps, degree of protection: IP20, including Inline connector

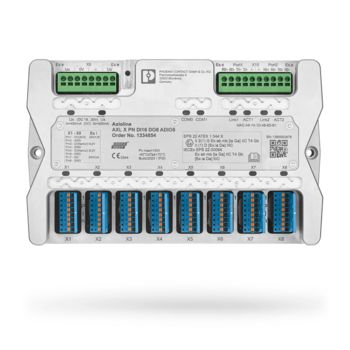

Axioline P, Digital input module, Digital inputs: 16, 24 V DC, connection technology: 2-conductor, transmission speed in the local bus: 100 Mbps, degree of protection: IP20, including bus base module and Axioline P connectors

Safety-related digital output module, IP20 protection, for the SafetyBridge system. The module has four safe digital outputs with two-channel occupancy or 8 safe digital outputs with single-channel occupancy

Axioline F, Analog input module, Analog inputs: 4, 0 V ... 5 V, -5 V ... 5 V, 0 V ... 10 V, -10 V ... 10 V, connection technology: 2-, 3-, 4-conductor, transmission speed in the local bus: 100 Mbps, integrated sensor supply, Extreme conditions version, degree of protection: IP20, including bus base module and Axioline F connectors

With a footprint of 15 mm x 62 mm, up to 16 connections can be realized on one Axioline Smart element. You can connect conductors with a conductor cross-section of up to 1.5 mm² with ferrules including plastic collars.

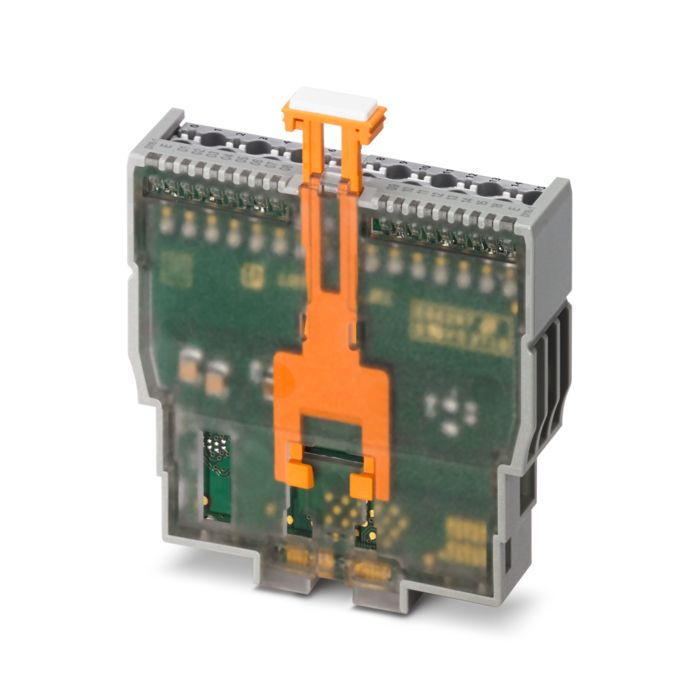

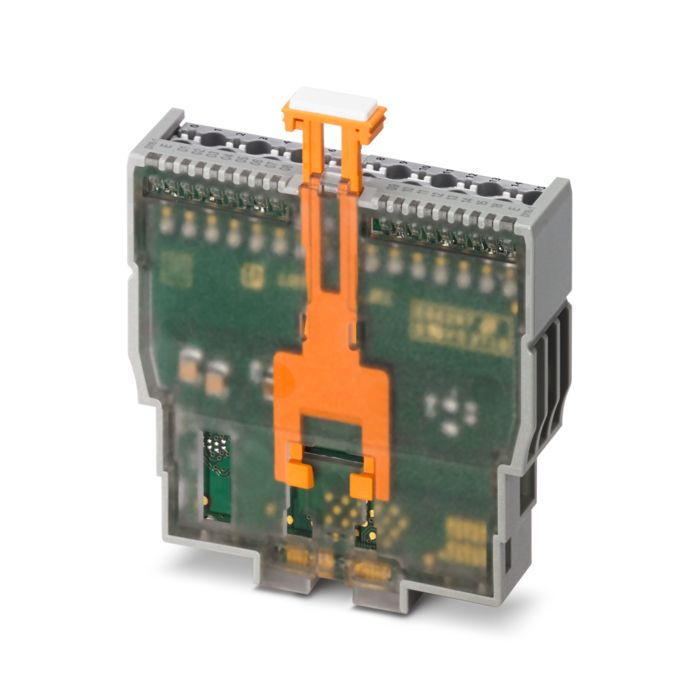

All Axioline Smart Elements feature Push-in connection technology throughout for the particularly fast connection of signals.

Axioline Smart Elements can be integrated into various solution concepts via the system-independent interface.

Axioline Smart Elements can be plugged easily into carrier modules with a suitable interface. Removal is child’s play thanks to a simple unlocking mechanism.

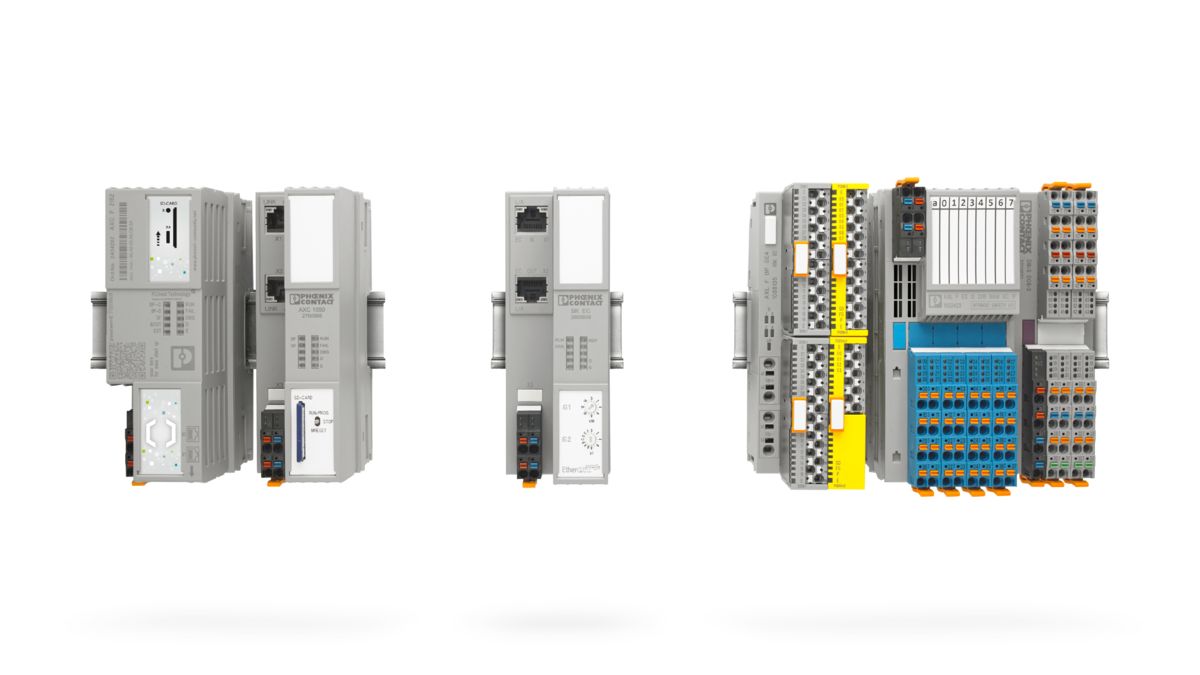

Axioline Smart Elements in the Axioline F remote I/O system

Within an Axioline F station, you can combine classic Axioline F modules with Axioline F backplanes including the Axioline Smart Elements in any way. You can therefore operate Axioline Smart Elements on already-existing Axioline F bus couplers or Axiocontrol controllers, such as PLCnext Control devices or classic PLCs.

The specially developed Axioline F backplanes feature four and six Smart Elements slots. With this flexibility, you can plug the Axioline Smart Elements into any position in the Axioline F backplane. The two-row design of the backplane enables an enormous reduction in the overall width of the I/O station.

Axioline F is the Ethernet specialist for control cabinet installation.

The portfolio features bus couplers for all common Ethernet systems.

PROFINET system redundancy: the AXL F BK PN TPS PROFINET bus coupler supports the specification for realizing S2 system redundancy using a single bus coupler. This means that the bus coupler can communicate with two redundant PROFINET controllers, thereby ensuring high systemic failsafe performance.

Reduce your installation times with Push-in connection technology. Clear wiring: the design supports cabling from above and below.

With the increased mechanical robustness, Axioline F has a vibration resistance of 5g, a continuous shock resistance of 10g, and a shock resistance of 30g.

Axioline F is a modular I/O system designed to meet every requirement. Fast signal acquisition increases your machine output, whether with a Phoenix Contact controller or in all common networks with a corresponding bus coupler.

Axioline F features a wide range of I/O modules with digital and analog inputs and outputs, functions, and for special applications. Implement safety applications with PROFIsafe or SafetyBridge Technology. The versatile I/O modules ensure flexibility in your station structure.

In harsh environments, reliable communication is essential. Axioline F features a particularly robust mechanical design. The XC versions with an extended operating temperature range of -40°C … +70°C are ideal for use under extreme conditions.

Due to their advantageous properties, the I/O modules have been approved by all major marine classification societies. Thanks to its low noise emission and robust mechanical design, Axioline F satisfies the stringent requirements for automation in shipbuilding.

The new generation of Axioline E devices are highly robust with their IP65/IP67 degree of protections and a fully-cast zinc die-cast housing.

Because of their outstanding resistance to EMI and the robust mechanics, you can minimize downtimes in your system with these devices.

Due to their extended temperature range and their strong resistance to environmental influences, common cooling and greasing agents, and welding beads, they can be used in many different applications.

The M12 Duo contour allows flexible field wiring with proven M12 screw connectors or the new M12 push-pull fast-connection technology.

Featuring tool-free assembly, the M12 push-pull fast-connection technology saves 80% of cabling time in comparison to the proven M12 screw connectors, and saves two minutes per device. Feedback via the latching of the connection plug as well as a tension test ensure high protection against errors during assembly.

The Axioline E devices of the new generation feature a high-performance L-coded voltage supply with 2x 16 A and can be used over significantly longer cable distances without additional feed-in cables.

You can also set up IO-Link substructures with minimum cabling effort and without additional feed-in cables with the high-performance IO-Link master ports with up to 2 A at L+ and up to 4 A at UA.

Our Axioline E-IO-Link clients of the new generation comply with IO-Link specification 1.1.3. With an I/O-Link master cycle time of <500 µs, they complete their information exchange with the connected IO-Link devices four times faster than commercially available first-generation IO-Link masters.

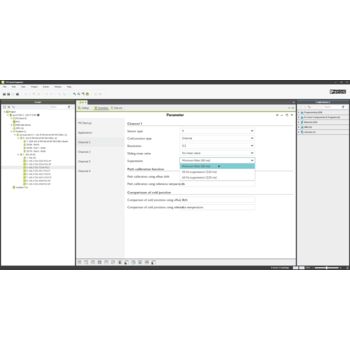

With their configuration options for connected IO-Link devices, the devices enable optimized integration into your automation system.

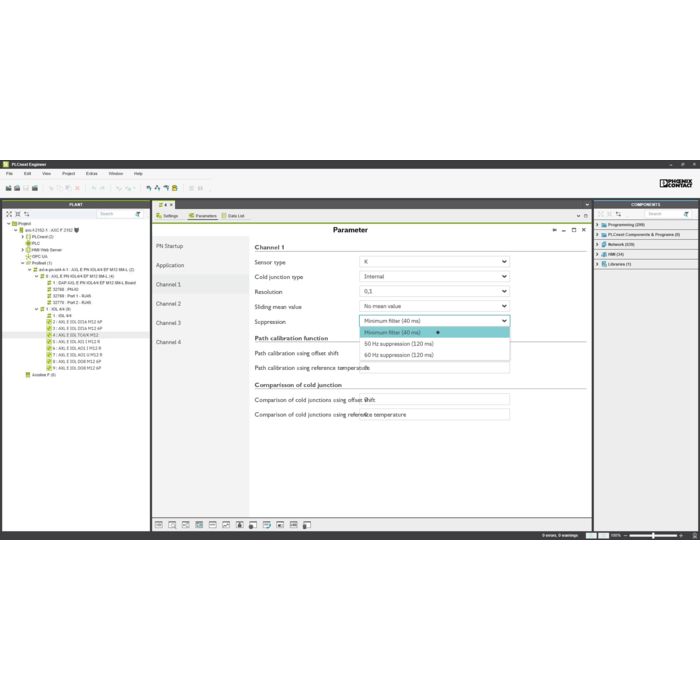

Configure any connected IO-Link devices in the PLCnext Technology automation system by simply integrating the IODD into your engineering system.

By importing the IODD, the mapping of an IO-Link device in the engineering system is identical to that of a PROFINET device. The device parameters from the IODD are automatically converted into startup parameters and downloaded during device startup together with the startup parameters of the PROFINET devices.

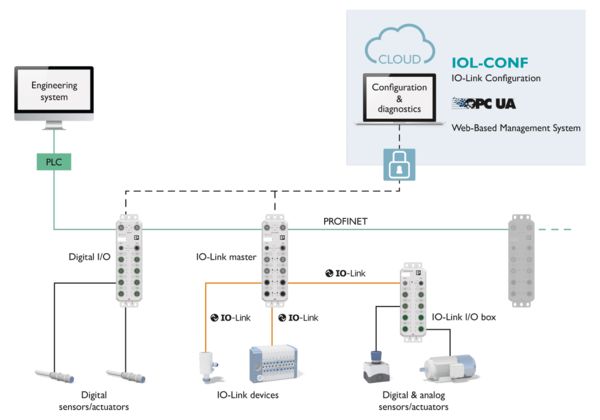

Open IIoT (Industrial Internet of Things)

The architecture of the new generation of Axioline E devices brings two communication paradigms together on one device platform in parallel and impact-free: The industrial real-time communication for established Industrial Ethernet protocols as well as safe, reliable, and open IIoT communication via OPC UA.

TSN (Time-Sensitive Networking)

The new generation of Axioline E devices support step-by-step all market-relevant Industrial Ethernet protocols such as PROFINET, EtherNet/IP™, Modbus/TCP, and EtherCAT®. With the innovative device architecture, the devices adapt flexibly to new technology standards and future networks such as PROFINET over TSN.

Industrial security

With the new generation of Axioline E devices, security characteristics are taken into account completely right from the design phase. As so-called “Secure-by-Design products”, these devices satisfy the requirements on the TÜV-certified process in accordance with IEC 62443-4-1. With built-in security features for field and cloud connectivity, these devices are ideally prepared for future automation tasks.

Access to device information and device configurations through optimum connectivity for future-proof automation

First generation Axioline E

Axioline E is the remote I/O system with a block design for field installation with M12 connection technology. A key characteristic of these devices is their openness to all common Ethernet-based communication protocols as well as PROFIBUS with a T-coded power supply.

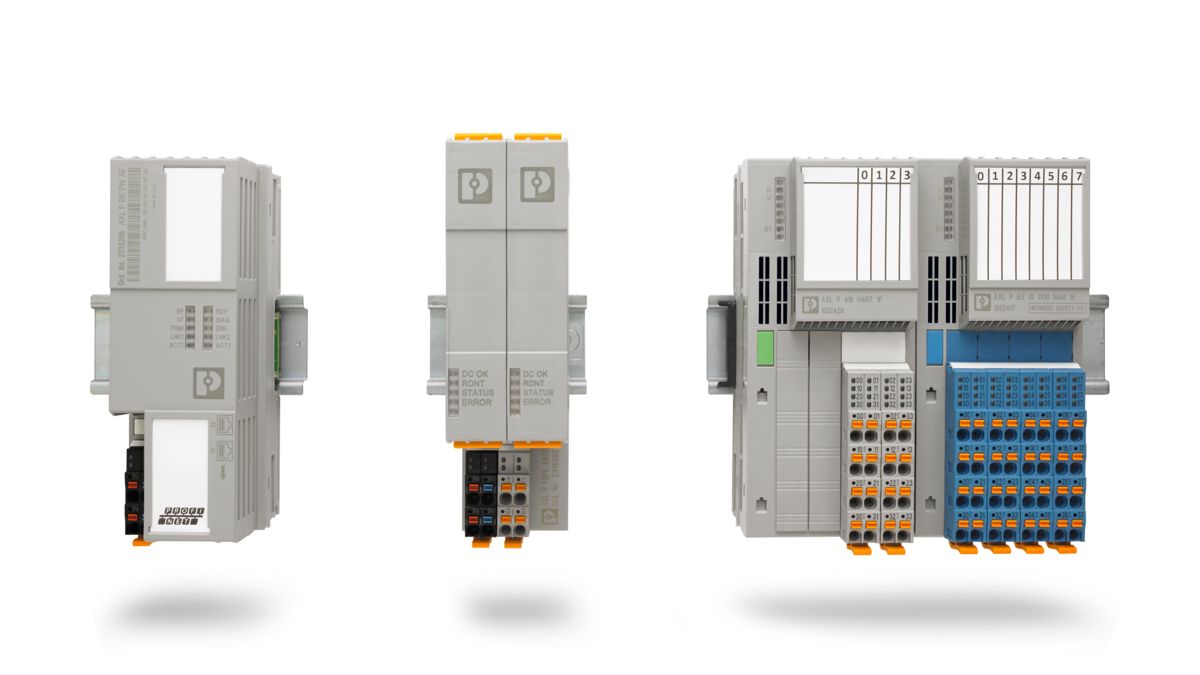

The Axioline P remote I/O system guarantees maximum availability for your application. With S2 redundancy, two PROFINET controllers can communicate with the I/O station at the same time.

When used in a Modbus TCP network, redundant communication can also be implemented using separate bus couplers, each with their own IP address.

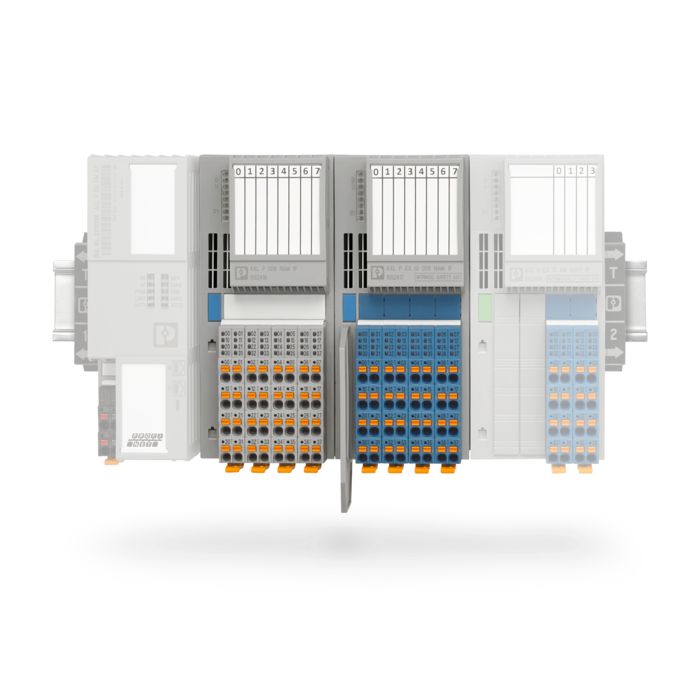

The hot-swap-capable local bus enables the replacement of existing modules from an Axioline P I/O station without having to switch off the system. The electromechanical design of the bus socket means that you can actually remove several modules from the station simultaneously, even without disrupting local bus communication.

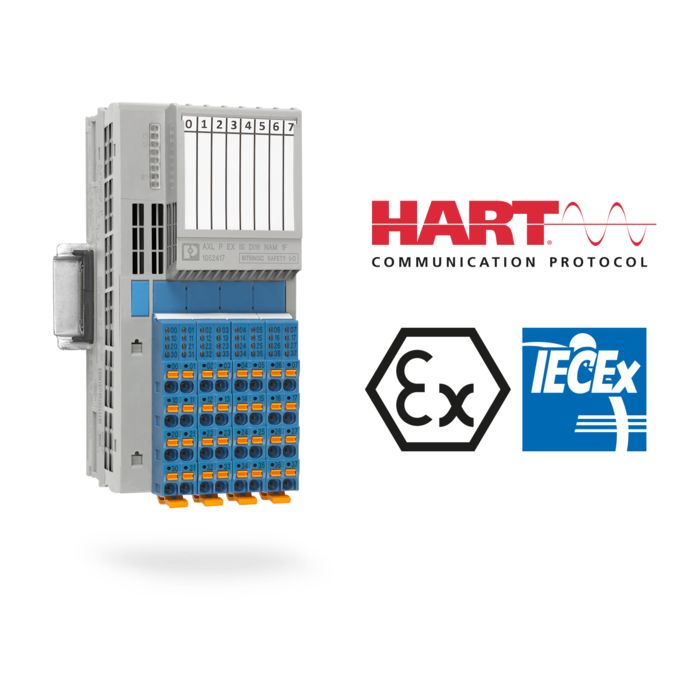

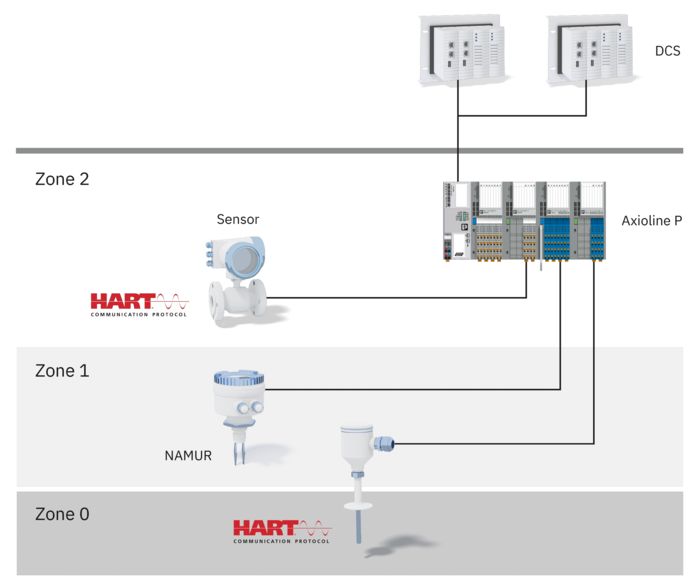

The intrinsically safe I/O modules can be installed in zone 2 and are suitable for the use of sensors as well as actuators up to zone 0. They feature HART communication and NAMUR functionality, making them particularly suitable for process automation applications.

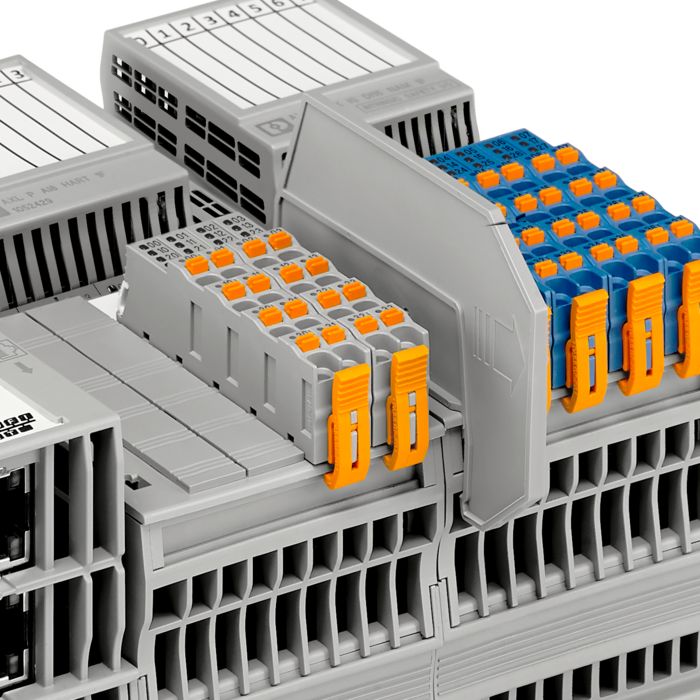

Standard modules can be combined with intrinsically safe modules particularly easily in the Axioline P I/O system. By positioning a partition plate (available as an accessory), the blue intrinsically safe modules can be added to the end of a station.

With the power supply integrated into each I/O module, the setup of an Axioline P station does not require an additional power supply. Furthermore, hot-swap capability is established when modules are removed due to the permanently live bus sockets.

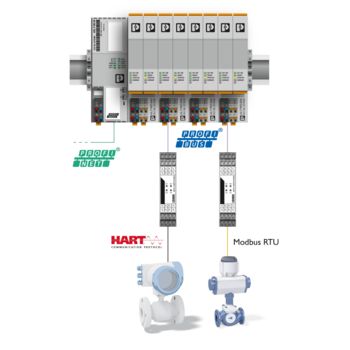

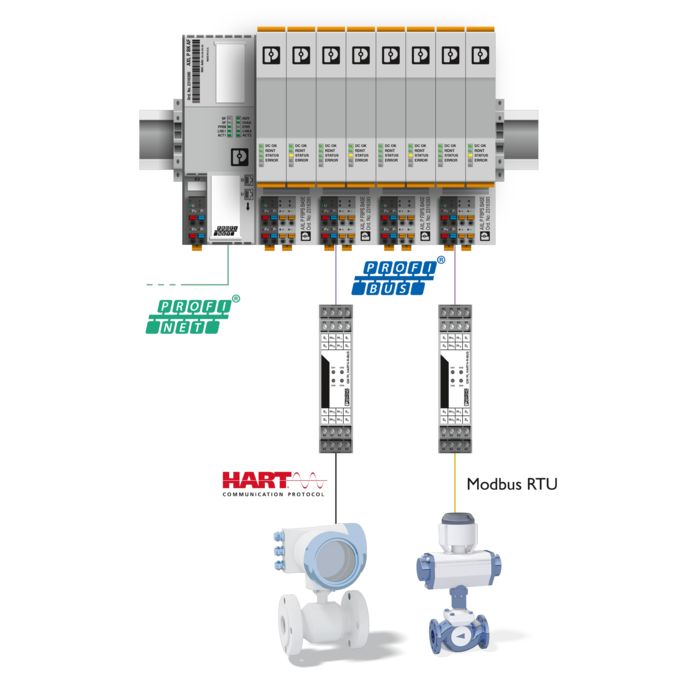

The modular station communicates with a PROFINET controller, for example a distributed control system (DCS), via a bus coupler. As an option, you can connect up to eight PROFIBUS PA segments to the individual proxy outlets in a compact way. To ensure the individual segments are immune to interference, appropriate shield connection technology is available. PROFIBUS PA sensors are connected directly to the modular Axioline P proxy.

Proven fieldbus technology, such as HART and Modbus/RTU, can therefore be integrated into PROFINET networks. This is done using PROFIBUS PA gateways that are connected to the modular Axioline P proxy.

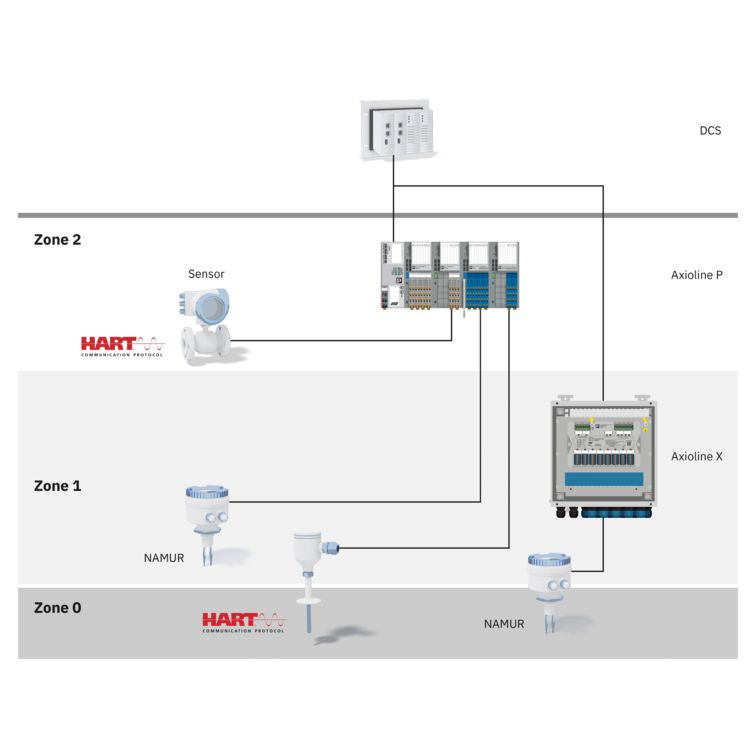

Connection of Axioline P through to zone 0

Axioline P devices can be connected directly to a distributed control system (DCS) in the form of a remote I/O system. PROFINET S2 system redundancy is supported, which ensures very reliable communication between the I/O station and DCS.

The Axioline P system can be installed in zone 2, and allows a direct connection of sensor and actuator signals from zones 2, 1, and 0. The portfolio includes important functions for process automation, such as analog input and output modules for HART communication as well as digital input modules for connecting NAMUR sensors.

This allows you to integrate intrinsically safe modules into the I/O station without additional components.

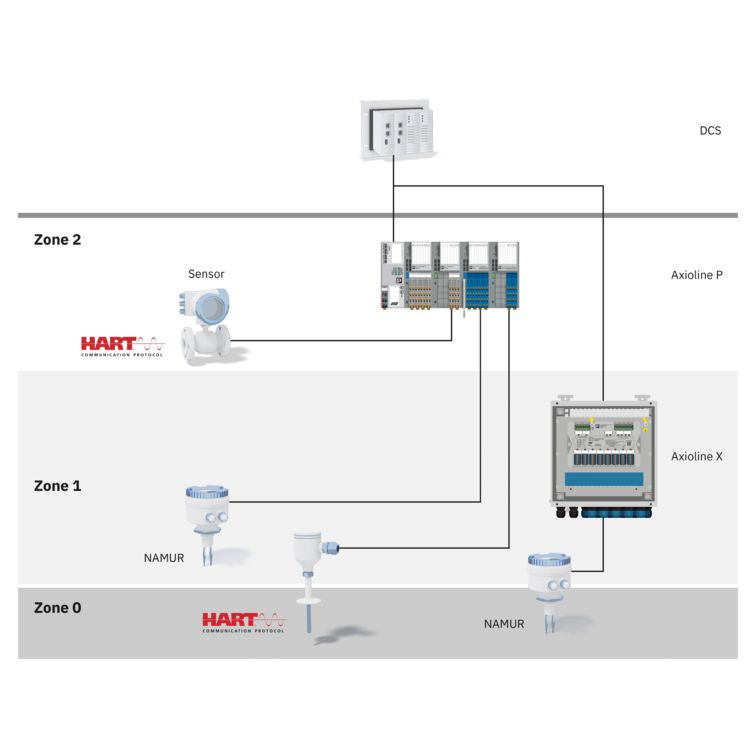

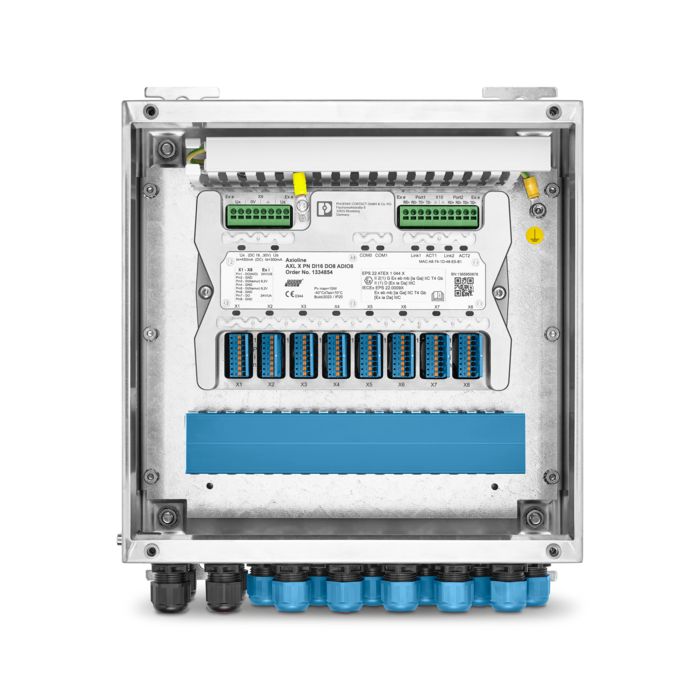

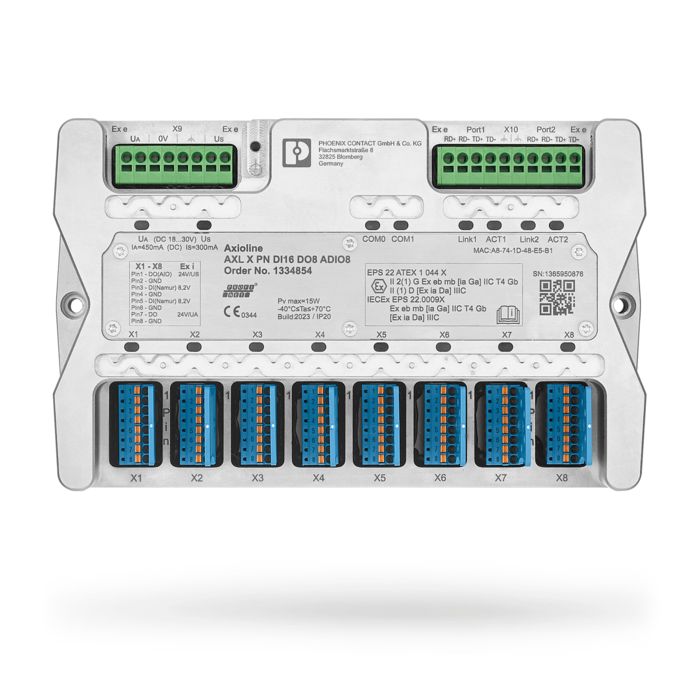

The Axioline X remote I/O preinstalled in a stainless steel box (degree of protection IP66). Complete with approvals in accordance with ATEX and IECEx. This saves installation effort in zone 1 and minimizes approval costs.

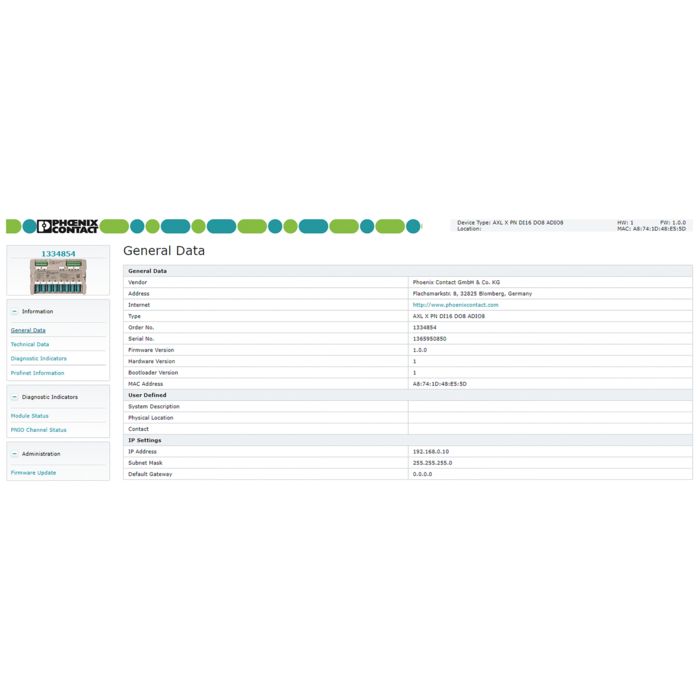

An integrated web server with diagnostic and firmware update functions enables easy and controller-independent operation.

Axioline X extends the solution space for cost-effective and targeted process automation. Together with the Axioline F XC and Axioline P product groups approved for process technology, we work with you to create scalable automation solutions.

Shorten signal paths, thereby reducing errors and additional costs. The direct installation of the Axioline X remote I/O modules in zone 1 with connection to a network without an additional isolator simplifies the system topology. Signals can be collected where they are generated.

Following the principle of “one terminal, one function”, you will find the right function for your application: from analog temperature measurement to digital communication. A broad portfolio of I/O terminals allows quick and easy integration in your system.

The standard function and analog terminals offer a wide range of options for setting parameters and operating modes. All functions can be flexibly adapted to the task.

The Inline ECO terminals can be combined with all Inline terminals and other Inline components.

Inline and PLCnext Technology go together. Using the AXC F IL ADAPT adapter terminal, Inline I/Os can be connected easily to a modular PLCnext Control device. Thus, a powerful PLCnext Control device can easily replace an older Inline controller.

Inline for building automation

You can use the powerful ILC 2050 BI controller to quickly and efficiently automate all subsections in building infrastructure, data centers, and decentral properties. The device features a variety of interfaces, and therefore supports all relevant building automation protocols. The extension with a large number of I/O components from the Inline system ensures the easy setup of a modular automation station. The data types of the various protocols are standardized, therefore enabling IoT-based automation.