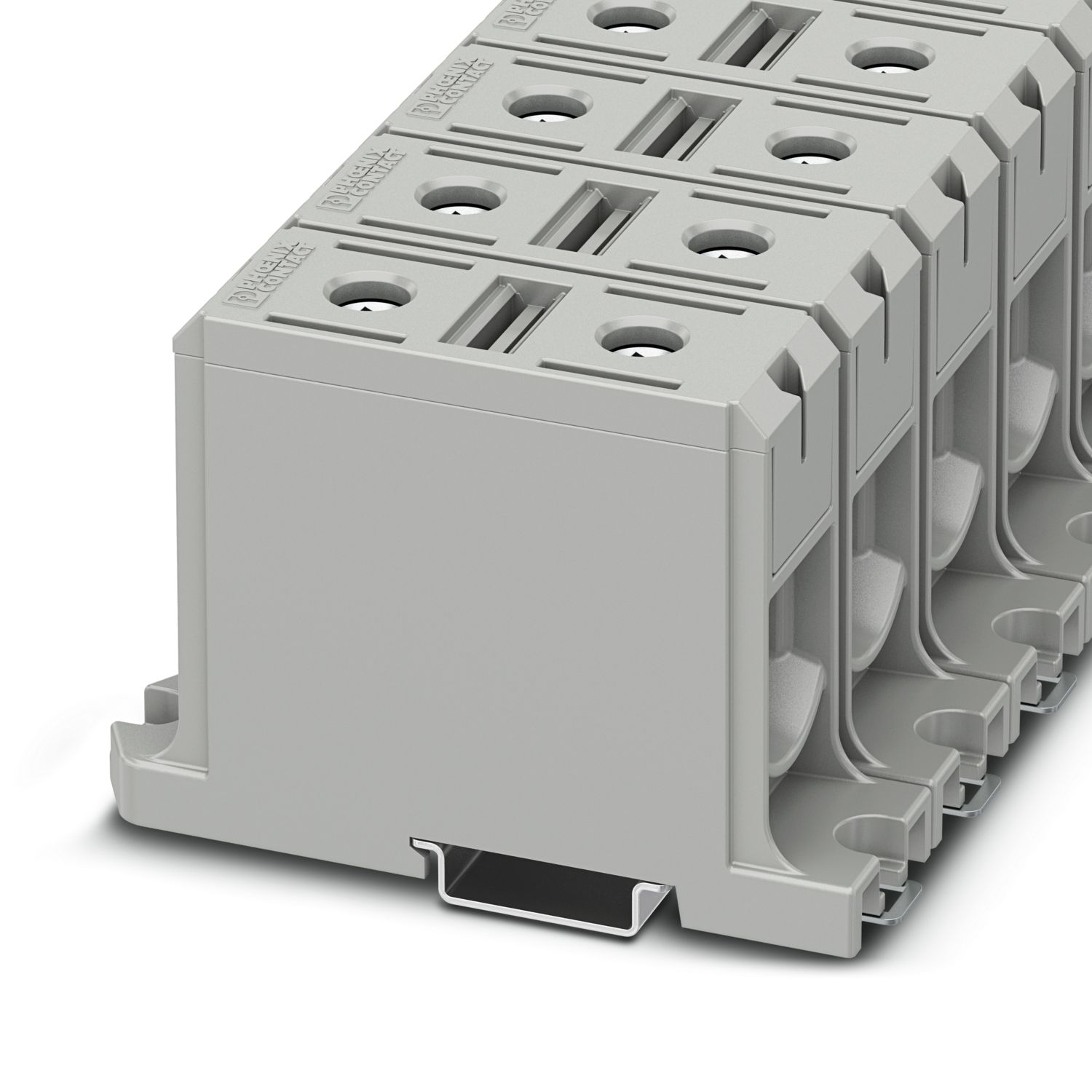

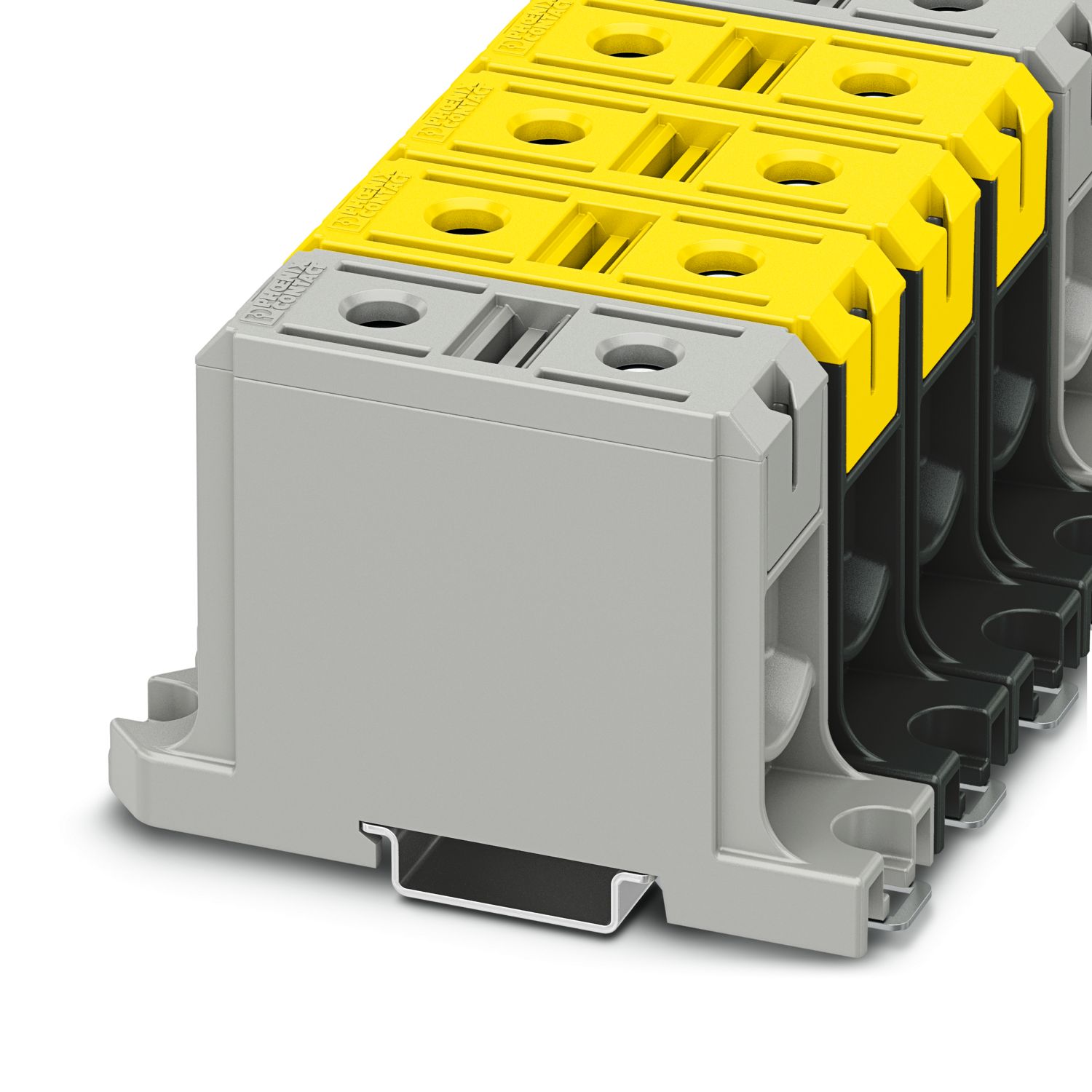

UBAL 150

-

High-current terminal block

1086498

High-current terminal block, nom. voltage: 1000 V, nominal current: 290 A, number of connections: 2, number of positions: 1, connection method: Screw connection, Rated cross section: 150 mm2, cross section: 35 mm2 - 150 mm2, Rated cross section: 150 mm2, cross section: 35 mm2 - 150 mm2, mounting type: NS 35/15, NS 35/7,5, color: gray

Connection cross-section

Product details

| General | Terminal block for aluminum and copper conductors (AL-CU) |

| General | |

| Note | We recommend using ferrules when using flexible donductor. |

| Product family | UBAL |

| Number of positions | 1 |

| Number of connections | 2 |

| Number of rows | 1 |

| Potentials | 1 |

| Insulation characteristics | |

| Overvoltage category | III |

| Degree of pollution | 3 |

| Rated surge voltage | 8 kV |

| Maximum power dissipation for nominal condition | 9.55 W |

| Nominal cross section | 150 mm² |

| Aluminum conductor | |

| Connection method | Screw connection |

| Screw thread | M18 |

| Note | Screws with hexagonal socket |

| The following values apply to aluminum conductors | |

| The values for aluminum conductors relate to rigid and multi-stranded conductors in accordance with EN 60228. Application notes on connecting aluminum conductors can be found in the download area. |

|

| Tightening torque | 20 ... 30 Nm |

| Stripping length | 30 mm |

| Connection in acc. with standard | IEC 61238-1 |

| Conductor cross-section rigid | 35 mm² ... 150 mm² |

| Cross section AWG | 2 ... 300 (converted acc. to IEC) |

| Nominal cross section | 150 mm² |

| Nominal current | 290 A |

| Maximum load current | 290 A (with 150 mm² conductor cross-section – test current in accordance with IEC 61238-1) |

| Nominal voltage | 1000 V |

| Copper conductor | |

| Note | The following values apply to copper wires |

| Flexible conductors, class 5, in accordance with EN 60228. | |

| Tightening torque | 20 ... 30 Nm |

| Stripping length | 30 mm |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 35 mm² ... 150 mm² |

| Cross section AWG | 2 ... 300 (converted acc. to IEC) |

| Conductor cross-section flexible | 95 mm² ... 120 mm² |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 35 mm² ... 120 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 35 mm² ... 120 mm² |

| 2 conductors with same cross section, flexible | 35 mm² ... 50 mm² |

| Nominal cross section | 150 mm² |

| Nominal current | 309 A |

| Maximum load current | 309 A (with 150 mm² conductor cross-section) |

| Nominal voltage | 1000 V |

| Width | 30.5 mm |

| Height | 105.5 mm |

| Depth | 67 mm |

| Depth on NS 35/7,5 | 67 mm |

| Depth on NS 35/15 | 74.5 mm |

| Hole diameter | 2.75 mm |

| Color | gray (RAL 7042) |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | II |

| Insulating material | PA |

| Relative insulation material temperature index (Elec., UL 746 B) | 400 °C |

| Surge voltage test | |

| Test voltage setpoint | 8 kV |

| Result | Test passed |

| Temperature-rise test | |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 150 mm² | 18 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 2.2 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | No |

| Mechanical strength | |

| Result | Test passed |

| Attachment on the carrier | |

| DIN rail/fixing support | NS 35 |

| Test force setpoint | 15 N |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Rotation speed | 10 rpm |

| Revolutions | 135 |

| Conductor cross-section/weight | 35 mm² / 6.8 kg |

| 150 mm² / 15 kg | |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 10 s |

| Result | Test passed |

| Oscillation/broadband noise | |

| Specification | DIN EN 50155 (VDE 0115-200):2018-05 |

| Spectrum | Long life test category 2, bogie-mounted |

| Frequency | f1 = 5 Hz to f2 = 250 Hz |

| ASD level | 6.12 (m/s²)²/Hz |

| Acceleration | 3.12g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

| Shocks | |

| Pulse shape | Half-sine |

| Acceleration | 30g |

| Shock duration | 18 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

| Ambient conditions | |

| Ambient temperature (operation) | -60 °C ... 110 °C (Operating temperature range incl. self-heating; for max. short-term operating temperature, see RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (operation) | 20 % ... 90 % |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 61238-1 |

| IEC 60947-7-1 |

| Mounting type | NS 35/15 |

| NS 35/7,5 |

| Item number | 1086498 |

| Packing unit | 10 pc |

| Minimum order quantity | 10 pc |

| Product key | BE1311 |

| GTIN | 4055626877990 |

| Weight per piece (including packing) | 153.45 g |

| Weight per piece (excluding packing) | 150 g |

| Customs tariff number | 85369010 |

| Country of origin | EE |

ECLASS

| ECLASS-13.0 | 27250101 |

| ECLASS-15.0 | 27250101 |

ETIM

| ETIM 10.0 | EC000897 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

| EF3.1 Climate Change | |

| CO2e kg | 1.447 kg CO2e |

Compatible products

-

CEC UBAL 150 - Cover plate 1086474

-

UCT-TM 10 - Marker for terminal blocks 0829142

-

UCT-TM 10 GN - Marker for terminal blocks 0829173

-

UCT-TM 10 RD - Marker for terminal blocks 0829169

-

UCT-TM 10 YE - Marker for terminal blocks 0829143

-

UCT-TM 10 BU - Marker for terminal blocks 0829172

-

UCT-TM 10 OG - Marker for terminal blocks 0829170

-

PXC TERMINAL GREASE - Antioxidant 1108540

Your advantages

Tailor-made screw connection for multi-stranded aluminum conductors and copper wires

Maintenance-free terminal points that are greased beforehand simplify the connection of aluminum conductors

Extremely robust housing made from fiberglass-reinforced polyamide with V0 approval

The special design of the UBAL enables the simultaneous connection of aluminum and copper conductors in various connections

PHOENIX CONTACT Israel Ltd.

P.O.B. 1799 Industrial Park Hasharon

Kadima 60920