Fast and reliable: Novum Automation trusts in Push-in Technology

- Novum Automation takes historically manual processes and automates them for optimum system control and an optimized return on investment (ROI)

- While upgrading a conveyor system, Novum discovered the fast, easy, and reliable Push-in Technology from Phoenix Contact

- Novum now trusts in Phoenix Contact products for most of its projects, because the faster installation time and high reliability save money in the long run

Customer profile – Novum Automation

Novum Automation is a small, innovative engineering and fabrication company located in Traverse City, Michigan. Novum takes on historically manual processes, such as data acquisition and product testing, over the entire life-cycle, and automates them for optimum system control and an optimized return on investment (ROI).

Reese Gallagher, owner and lead systems engineer at Novum, explained, “We’re a fairly young company and just recently rebranded from Gallagher Engineering to Novum Automation. We are a team of five engineers with wide-ranging interests. We want to do our job to the best of our ability and have fun doing what we do. We hold ourselves to a pretty high benchmark.”

Reese stated: “In our industry, we’ve reached a point where equipment has been installed for the last 20, maybe even 30 or 35, years. There’s a need to update that old equipment, since a lot of older technology is no longer supported. It’s starting to have many issues, and there’s a high demand for upgrading control systems in manufacturing plants. We’re seeing high demand in the Northern Michigan area, where industry has grown, yet the control support has not really grown with it. We’re starting to find common needs among our customers.”

Modernizing the conveyor control system

Novum Automation sees this issue across many types of applications, such as conveyor systems.

Novum had a client who needed to upgrade conveyor systems on four bottling production lines. The original system ran on obsolete hardware, which negatively impacted operational productivity.

Reese explained, “A lot of manufacturing companies have conveyors moving their product throughout the facility.

There has to be some form of a control system with handshaking between machines, so the operators know when products are backed up or jammed in the plant. We also offer inline inspection devices. “We’re starting to develop a standard solutions portfolio. It became clear to us that we are building a lot of conveyor control systems.

So we had to ask ourselves: 'Why not just design a standard solution that we can market specifically for this purpose?'”

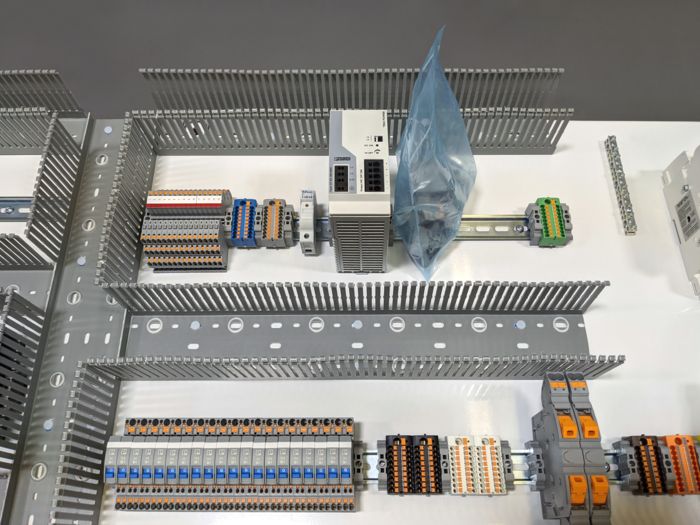

Novum designed, developed, installed, and commissioned a fully functional conveyor control system. The system is based on the latest scalable, future-proofed PLCs and panel-build hardware, and is delivered with comprehensive documentation for operator usability.

The new system included digital photocells to detect bottle jams, variable frequency drives (VFD) to smooth out acceleration/deceleration events, which maximizes the motor service life, and new AC drives offering higher reliability and safety.

Novum had to complete all four systems in just four months, so the company needed to work fast.

Wiring terminal blocks can be a time-consuming task.

While terminal blocks are one of the most basic components in a control cabinet, wires sometimes come loose over time, which causes problems.

Reese said: “After five hours of troubleshooting, we would find out that one of the terminals was not tightened all the way, and that gravity had pulled out the conductor.

Or maybe someone came in and bumped it.

The conductor comes loose, and now we have to somehow troubleshoot a thousand different points of contact to figure out which wire is not connected.”

Push-in Technology for quick and easy installation

After seeing some panels built with Phoenix Contact products, Reese was interested in learning more about Push-in Technology (PT). “When we saw it, we thought, ‘Wait – there's something on the market where you just push the conductor in? And then it just stays in, and it holds well, and it resists vibration?’ We were wondering, ‘Why isn’t everyone doing this?’”

Reese admits he was initially a bit overwhelmed by Phoenix Contact’s wide-ranging product line, but Zach Vinski, the industrial sales engineer taking care of Novum, helped guide him through the catalogs.

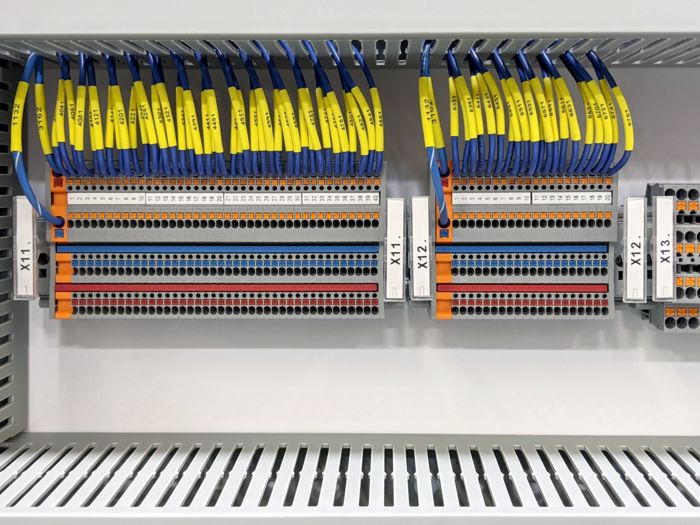

“Zach has done an amazing job at orienting us and helping us home in on the right products.” Novum specified the PTPOWER high-current terminal blocks and the PTIO sensor/actuator terminal blocks. PTPOWER offers fast, user-friendly connection options for wiring large conductors of up to 350 kcmil (177 mm²). The PTIO is designed for wiring modern machine controllers. These terminal blocks have the same shape as the CLIPLINE complete jumper system from Phoenix Contact and offer maximum flexibility.

Novum had a very tight turnaround to complete the conveyor control systems. “We built four of these systems within about four months,” said Reese. “We had to build these systems extremely fast, and one of the great advantages of PTPOWER and the PT terminal blocks in general is that they save time. We’re not screwing things in.

I used to get tennis elbow from screwing in so many terminal blocks, so I’m a big supporter of PT. The time savings enabled us to build the systems quicker. “They’re also touch-proof, which is amazing. But they are also quick and easy to use. Nothing needs to be tightened.” He said that the PTIO’s narrow size was another benefit. "It is a nice sensor I/O. Basically, you supply power to it, and then just work with jumpers from there. This design is very slim. Wherever you can position a proximity sensor, you can also route the I/O very efficiently. The electricity is already there. You do not have to run individual power lines. That is amazing, and yet you can still get the I/O directly from it. So this is another area of application, in addition to the designs with standard feed-through terminal blocks.”

After using Push-in terminal blocks, anything else looks outdated, so we have been asking customers if they want to upgrade.

Connections you can trust in the long run

Novum fully overhauled all four control systems within the tight four-month timeline.

They were able to limit the new system’s footprint to just two standing control cabinets, compared with three or four in the old system.

Reese said Novum uses PTPOWER for all of its main power distribution applications. “And we use PT terminal blocks in almost all of our applications now. The selection is so great that you can also buy double level versions. There is even a triple level. Also very interesting is the version for AC motors. In this case, the ground potential is also included, meaning that you can quickly terminate at the input or output going into or coming out of a VFD.

Then the field wiring can be inserted and connected directly.

After using Push-in terminal blocks, everything else seems obsolete, so we asked customers if they wanted to upgrade.” Reese said that Push-in Technology and other Phoenix Contact products save money in the long run. “Phoenix Contact products, and in particular push-in terminal blocks, save us a lot of time when building a panel. In addition, you can also consider the long-term effects of what is, in my opinion, a quality product. It’s not going to break down in the field, unless someone tampers with it. So, we don’t get calls telling us that something is not working.”

“What I like about Phoenix Contact is I can trust their product line. I do not have to bring the products for quality testing first. I don’t have to be concerned that a product is going to break down in an unexpected way after two years, or even during startup,” he concluded. “When I decide to use Phoenix Contact, it lessens the load on my shoulders, lets me sleep better at night, and I just know that the product they’re selling me is going to do what it is designed to do.”