Digitizing analog signals

In industrial measurement technology, the classic 4 to 20 mA signal is still a widely used standard today. Specialists from the fields of planning, installation, and maintenance appreciate the high ease of maintenance and the universal application possibilities of this established analog technology. The plug-in gateways of the MINI Analog Pro product family from Phoenix Contact now enable the integration of these signals into industrial bus systems and networks. This opens up new potential for plant operators.

Challenges

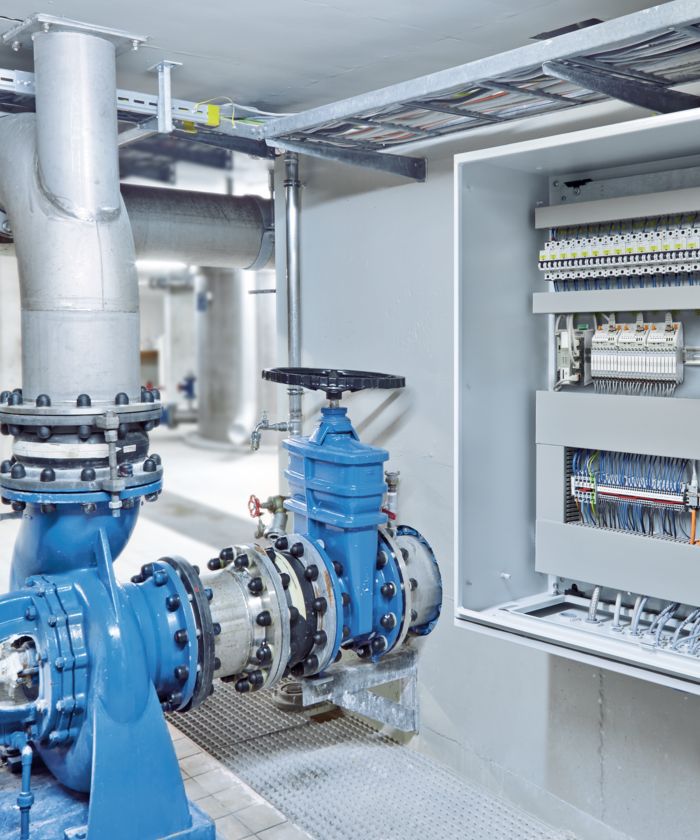

Considerable wiring effort in classic closed-loop control circuits

The classic structure of a closed-loop control circuit in automation and process control engineering consists of the sensors located in the field, a central control unit for signal processing, usually in the central control cabinet, and the actuators, which are also located in the field. Signal conditioners and measuring transducers are used as links between the field sensor system and the control level and are usually connected to I/O modules.

In order to transmit the signal from a measuring point to the controller, a considerable amount of wiring is required. This costs time and is prone to errors.

Another disadvantage is the large amount of space required. The interface technology and the I/O level, for example, for eight signals, usually require about 15 cm of space on the DIN rail before the actual controller.

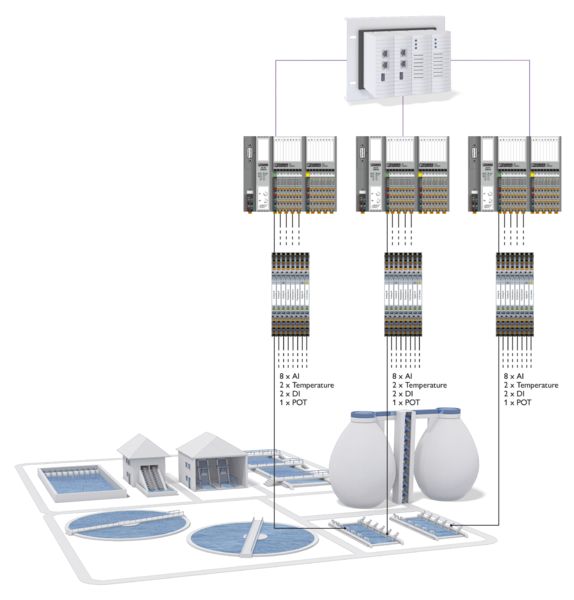

Classic structure of a closed-loop control circuit

Classic closed-loop control circuit with signal conditioners and I/O level

Our solution

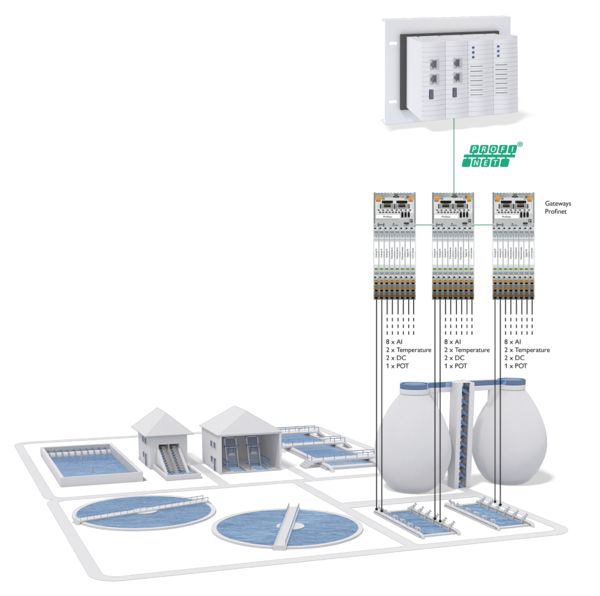

MINI Analog Pro daisy chaining with PROFINET gateways

Combination of electrical isolation and digital communication Easy integration into PROFINET networks

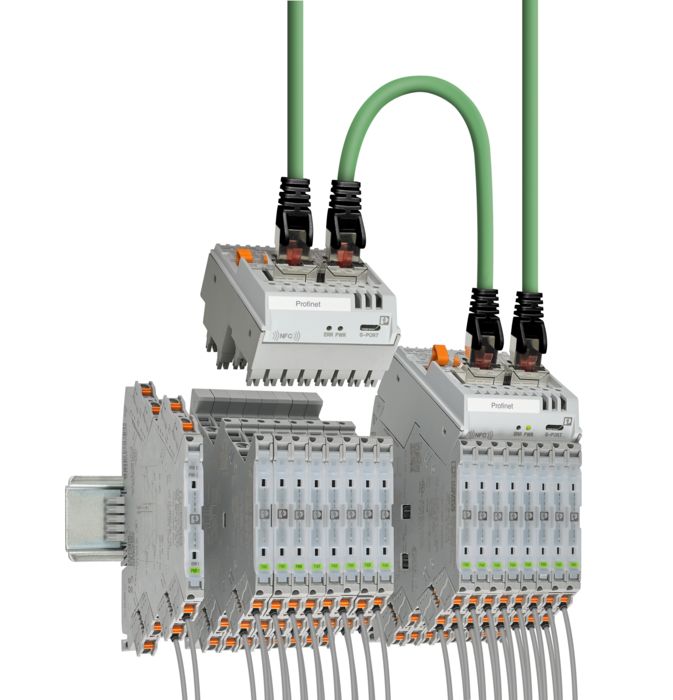

Using the MINI Analog Pro PROFINET gateway, various analog and digital signals can be integrated into PROFINET networks. The switch from PROFIBUS to PROFINET protocol is particularly interesting for refitting projects.

The gateway has been certified by the PROFIBUS Nutzerorganisation e.V. user organization in accordance with Conformance Class C and can therefore be easily migrated into a wide range of applications.

The plug-and-play principle also helps in this application. Disconnect the output terminal on the MINI Analog Pro signal conditioners, plug in the PROFINET gateway, connect the network cables – and you’re done.

Additional gateways are available for the following protocols: Modbus/TCP, Modbus/RTU, and PROFIBUS

Your advantages

- Network integration of signal conditioners in any combination by using compact gateways

- Interference-free signal transmission to the CPU with safe electrical isolation

- Reduces costs and saves space by omitting signal-specific input cards Fast, error-free bundling of signals in one network cable

- Measure current signals during operation or take readings using the app

Leap into the digital world

MINI Analog Pro gateways enable the connection of classic signal conditioners directly to serial communication protocols, such as Modbus, PROFIBUS, or PROFINET.

The output signals of the signal conditioners and measuring transducers are digitized in the gateway and transmitted directly from the interface level to the control system or controller. This means that an additional I/O level can be completely eliminated in certain applications.

With a pitch of only 6.2 mm, it enables temperatures, frequencies, 0 to 10 V signals, 4 to 20 mA signals, switching contacts, and many other signal types to be read in simultaneously. This reduces the additional wiring effort and also prevents wiring errors.

Structure of a closed-loop control circuit with MINI Analog Pro PROFINET gateways

System topology with PROFINET gateways

Summary

MINI Analog Pro makes 4 to 20 mA signals fit for PROFINET

The particular advantage of using MINI Analog Pro is its highly flexible range of applications. On the one hand, this is the result of the extensive product range of signal conditioners and measuring transducers, which provides the right solution for almost every application. On the other hand, the optional plug-in communication gateways enable simple integration of classic signals from analog technology into digital transmission protocols. The combination of signal conditioners and communication gateways produces a compact, flexible, and efficient solution for the next step towards digitization and Industry 4.0. The MINI Analog Pro makes 4 to 20 mA signals fit for PROFINET.