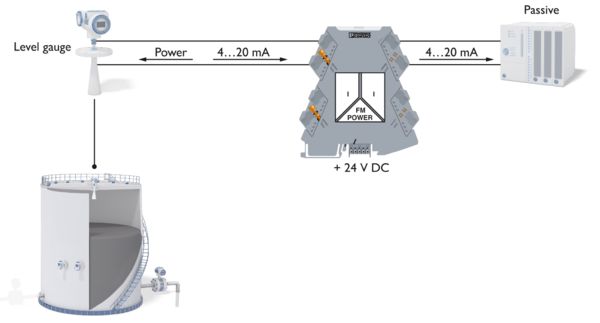

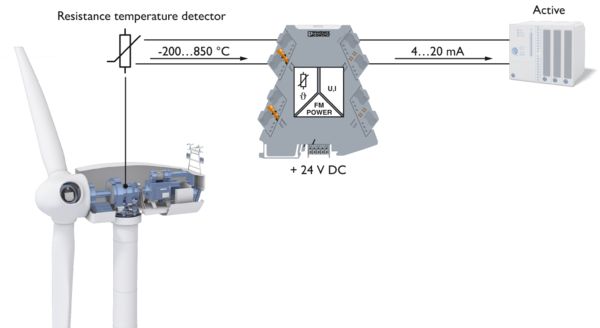

A typical example in the field of power generation is processing temperature sensor signals to monitor the turbine, generator, and shaft temperature in facilities such as reservoir hydroelectric power plants.

Accurate temperature measurement is essential for operating a hydroelectric plant. It protects the plant from premature wear, damage, and failure due to increased friction. This is detected through temperature.