PCB assembly With our PCB connection technology, you can freely select the appropriate mounting type. It is suitable for manual assembly as well as semi- and fully automated production processes. This means that you can assemble PCBs efficiently and process them reliably. Find out here about the areas of application of the different mounting types and soldering processes for PCBs as well as their requirements and advantages.

Soldering processes

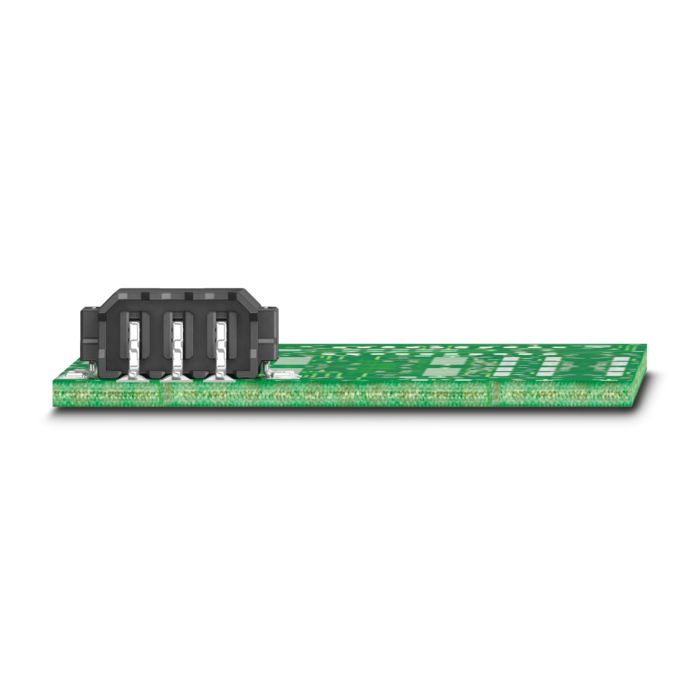

In the case of SMT soldering, components are soldered onto the upper side of the PCB

SMT soldering – a modern soldering process

Surface mounting technology (SMT) is the basis for modern component assembly. In contrast to the through-hole assembly of wired components, SMD components (surface mount devices) have solderable connection surfaces that are soldered directly onto the upper side of the PCB using the reflow soldering process. SMT soldering makes it possible to optimize component assembly in terms of inexpensive and high-quality PCB assembly.

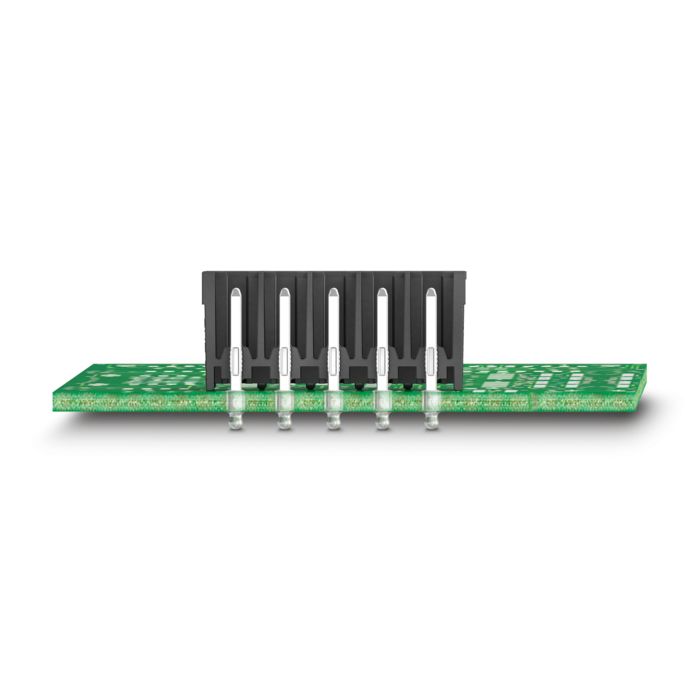

In the case of THR soldering, wired components made of high-temperature material are integrated into the SMT process

THR soldering – mechanical strength with automatic assembly

Through-hole reflow (THR) soldering combines the solder connections of through-hole technology, which are particularly stable in mechanical terms, with the production processes of surface mounting, which can be automated efficiently. In the THR process, the solder paste is pressed into the through-contacted holes using the same process equipment. The functional principle of this method is today regarded as being established and has been accounted for in a separate standard, DIN EN 61760-3.

Wave soldering is a classic soldering process, particularly for wired components

Wave soldering – a quick and cost-effective soldering process

In the case of wave soldering, depending on the assembly method, wired components or connection elements are soldered onto the PCB manually or using pick-and-and-place machines. First, the entire module is wetted with flux on the solder side, then pre-heated, and finally run through a single or double solder wave where it is wetted with the solder. After soldering, the entire module is cooled in order to reduce the thermal load on the PCB again. If only through-hole technology (THT) components are soldered, which by virtue of their design must withstand greater mechanical strain, wave soldering is always the standard method.

Solder-free mounting methods

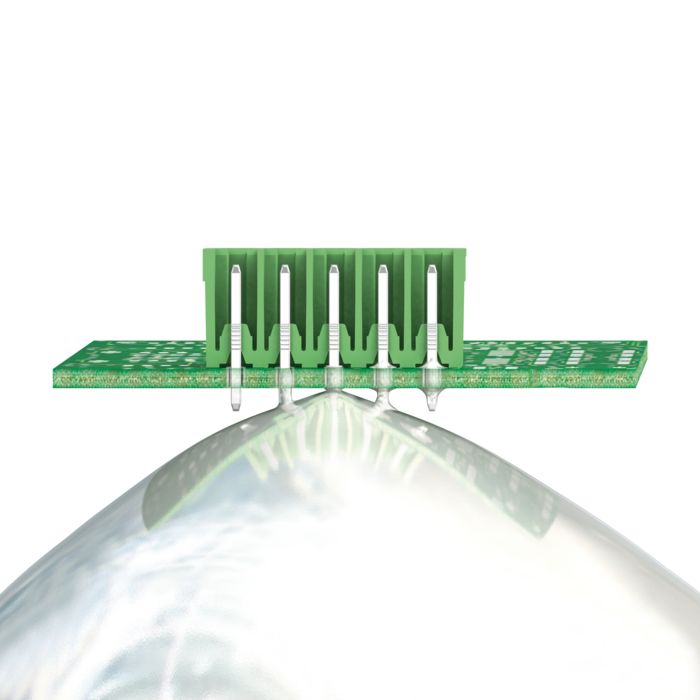

In the case of direct connection, the connectors are attached to the contact pads on both sides of the PCB

Direct-connection technology – the flexible solution for wire-to-board and board-to-board applications

In the case of direct connection, the direct connector contacts the corresponding contact pads on the edge of the PCB. As a result, wire-to-board and board-to-board connectors can easily be plugged horizontally onto 1.6 mm thick printed circuit boards without any additional tools. The male connectors are coded at the factory to prevent mismatching. Two spring-loaded engagement catches lock the connectors in place on the PCB. As the soldering process is eliminated, the connection components are not subjected to thermal stress.

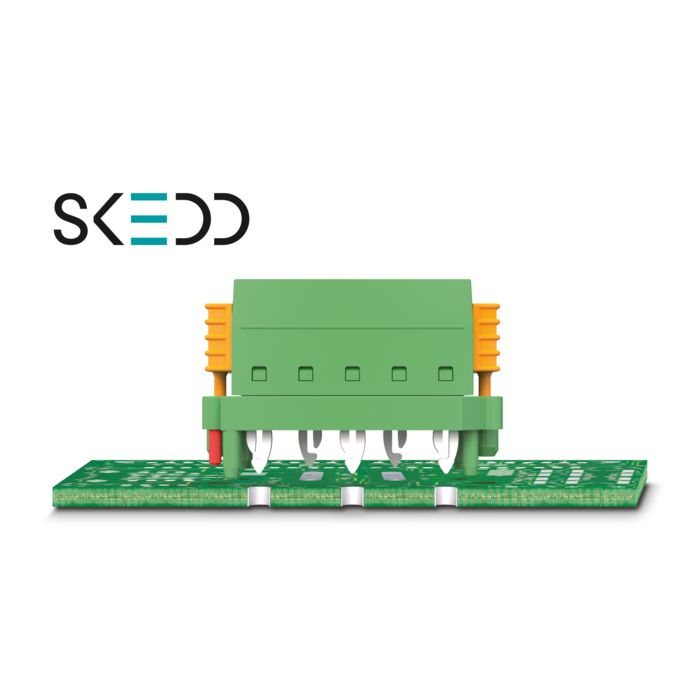

SKEDD – innovative direct connection technology

SKEDD is an innovative mounting technology for connecting PCB connectors directly to the PCB via through-contacted drill holes. Mounting is tool-free and no additional header is required. Body-bound rivets on the side of the connector ensure a reliable and vibration-resistant connection. SKEDD direct connectors from Phoenix Contact are based on licensed technology from Würth Elektronik. Like the entire PCB connector range, the direct connectors are certified in accordance with standard DIN EN 61984.

Connectors for SMT production brochure

Gain a better understanding of SMT production

Learn about the fundamentals of modern assembly manufacturing using SMT and THR technology. The brochure also includes a product overview of PCB terminal blocks, PCB connectors, and circular connectors for THR and SMT soldering. The glossary at the end of the brochure explains important technical terms used in SMT production.

Download the brochure here: