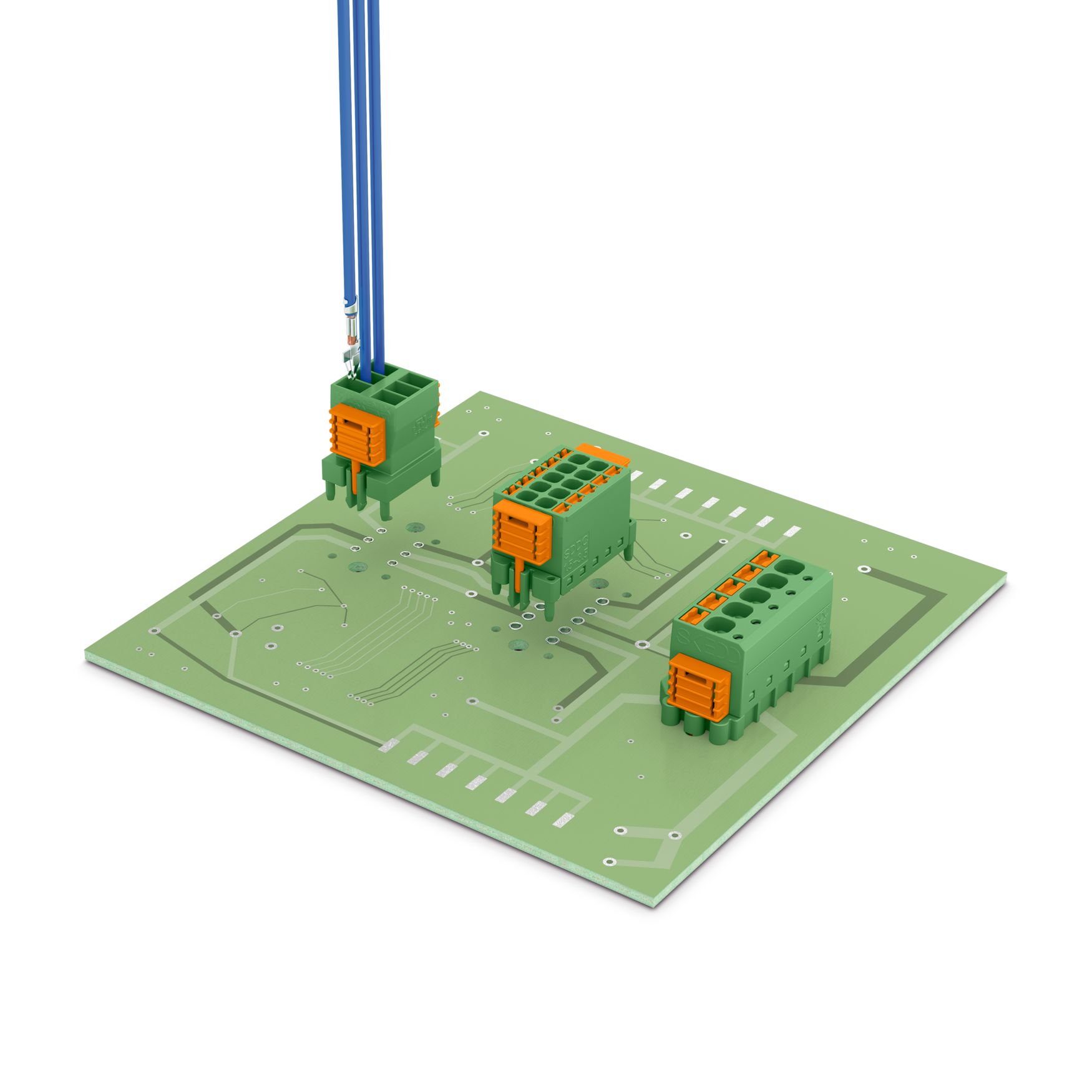

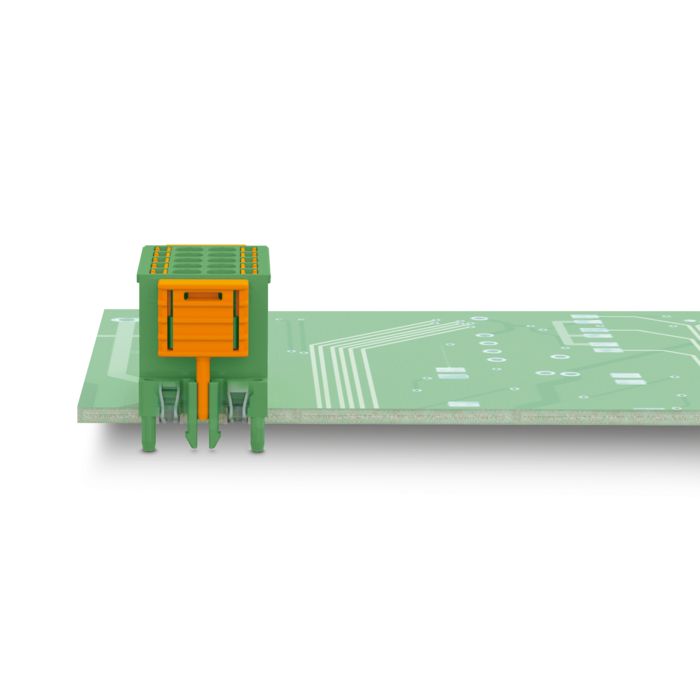

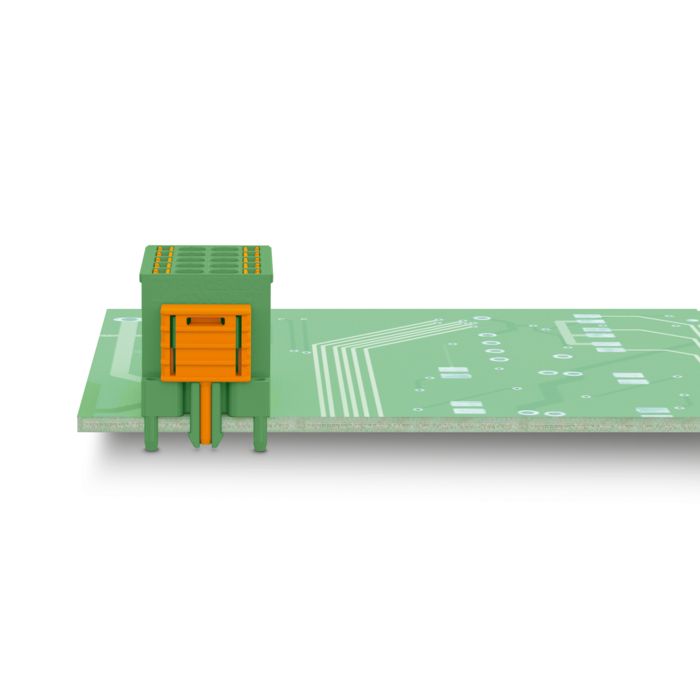

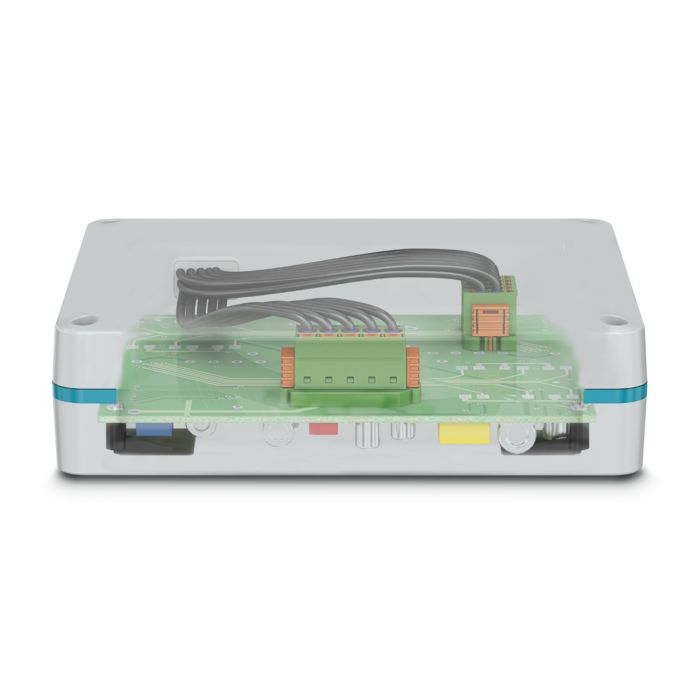

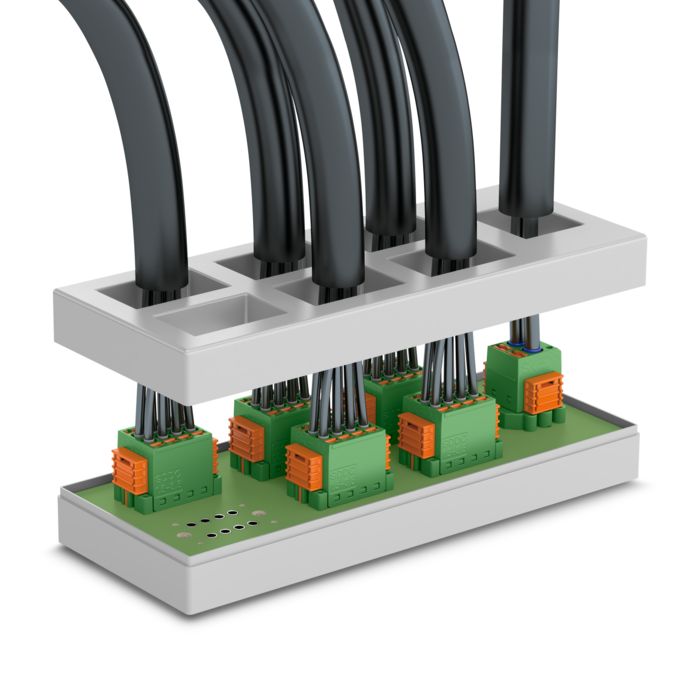

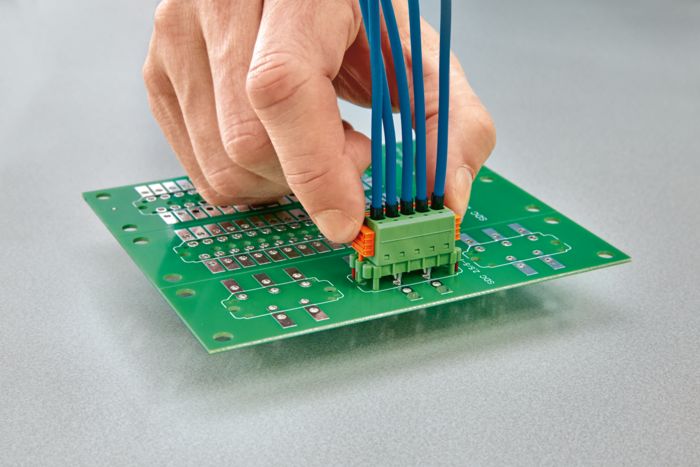

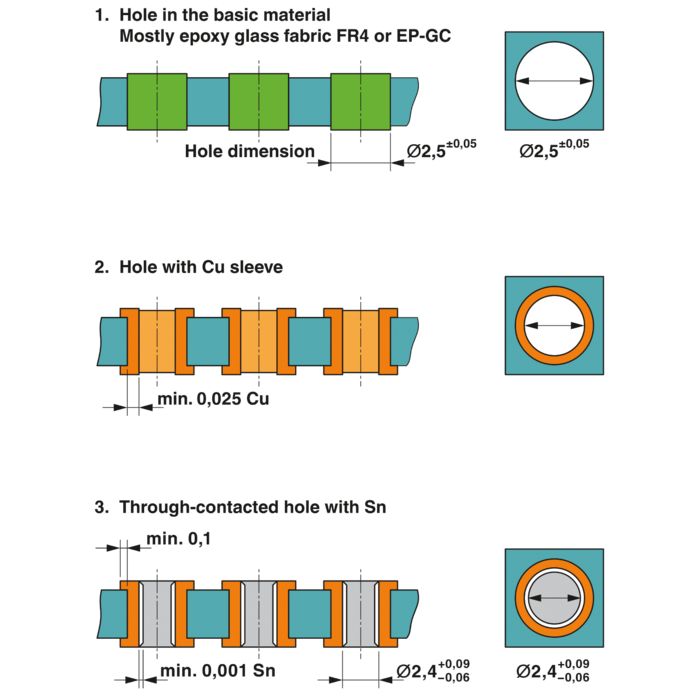

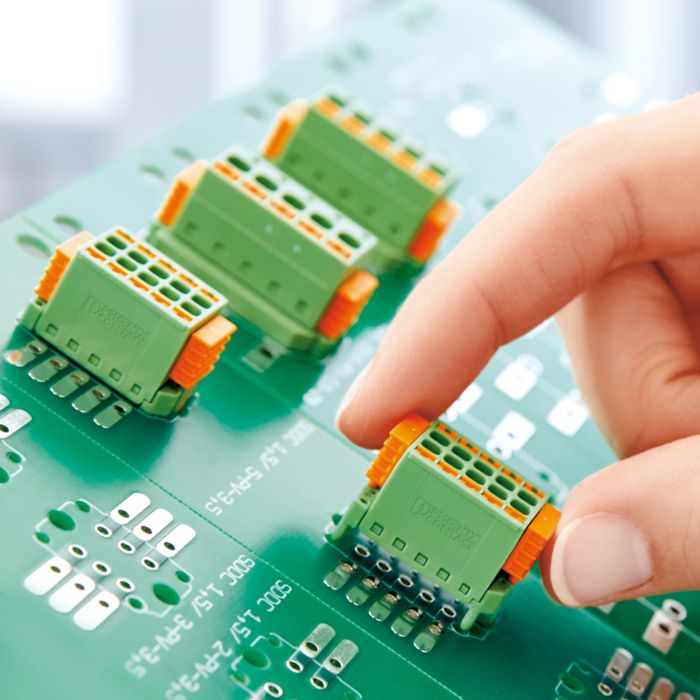

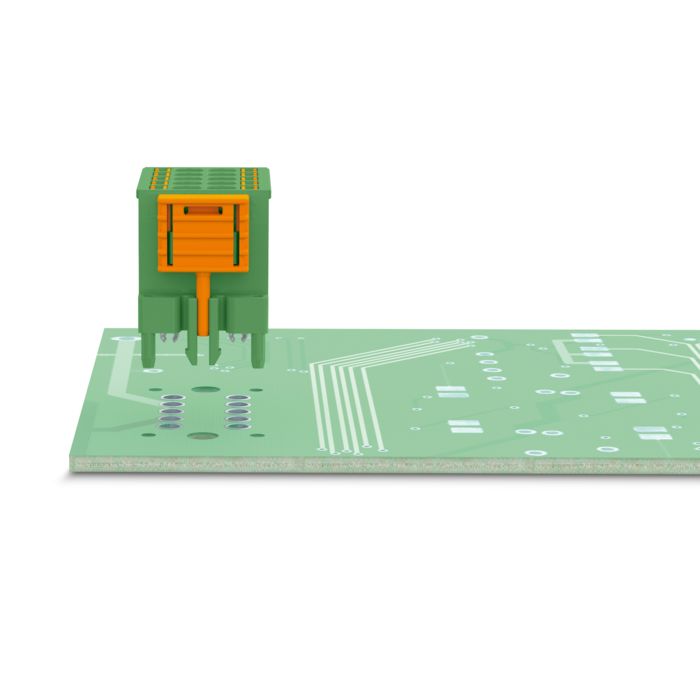

Press-in technology, wave soldering, THR soldering, and SMT soldering are established in PCB assembly. None of these are needed with the SKEDD direct-connection technology. Integrate through-contacted drill holes anywhere on the PCB. giving you a whole new level of flexibility when it comes to your PCB layout.