PTRE 6-2/7

-

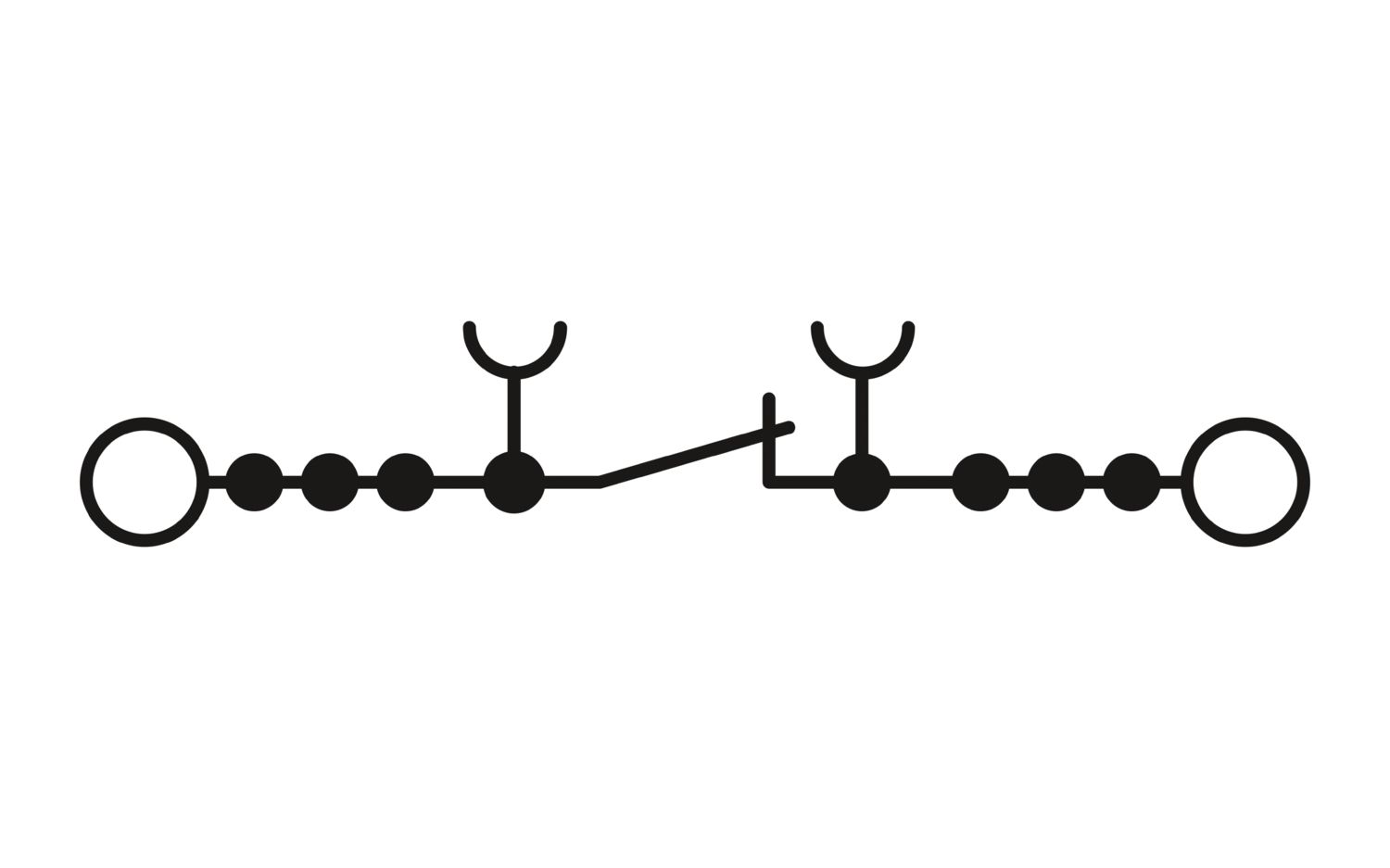

Test terminal strip

3069852

Test terminal strip, nom. voltage: 400 V, nominal current: 24 A, number of connections: 14, number of positions: 7, connection method: Push-in connection, Rated cross section: 6 mm2, 1 level, cross section: 0.5 mm2 - 10 mm2, mounting type: DIN rail mounting, color: gray

Product details

| Number of positions | 7 |

| Pitch | 8.2 mm |

| Number of connections | 14 |

| Number of rows | 1 |

| Potentials | 7 |

| Insulation characteristics | |

| Overvoltage category | III |

| Rated surge voltage | 4 kV |

| Maximum power dissipation for nominal condition | 1.31 W |

| Test surge voltage | 5 kV |

| Nominal cross section | 6 mm² |

| 1 level | |

| Connection method | Push-in connection |

| Stripping length | 12 mm |

| Internal cylindrical gage | A5 |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 0.5 mm² ... 10 mm² |

| Cross section AWG | 20 ... 8 (converted acc. to IEC) |

| Conductor cross-section flexible | 0.5 mm² ... 6 mm² |

| Conductor cross-section, flexible [AWG] | 20 ... 10 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.5 mm² ... 6 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.5 mm² ... 6 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 1.5 mm² |

| Nominal current | 24 A |

| Maximum load current | 30 A (with 6 mm² conductor cross-section) |

| Nominal voltage | 400 V AC/DC |

| Nominal cross section | 6 mm² |

| 1 level Connection cross sections directly pluggable | |

| Conductor cross-section rigid | 1 mm² ... 10 mm² |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 1 mm² ... 6 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 1 mm² ... 6 mm² |

| Width | 89.7 mm |

| Height | 99.7 mm |

| Depth | 56.5 mm |

| Depth on NS 35/7,5 | 61.8 mm |

| Depth on NS 35/15 | 69.3 mm |

| Pitch | 8.2 mm |

| Color | gray (RAL 7042) |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Temperature index of insulation material (DIN EN 60216-1 (VDE 0304-21)) | 125 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Calorimetric heat release NFPA 130 (ASTM E 1354) | 27,5 MJ/kg |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Mechanical data | |

| Open side panel | No |

| Ambient conditions | |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 60947-7-1 |

| Mounting type | DIN rail mounting |

| Item number | 3069852 |

| Packing unit | 1 pc |

| Minimum order quantity | 1 pc |

| Note | Made to order (non-returnable) |

| Sales key | BE06 |

| Product key | BE6112 |

| GTIN | 4055626064864 |

| Weight per piece (including packing) | 259.3 g |

| Weight per piece (excluding packing) | 99.99 g |

| Customs tariff number | 85369010 |

| Country of origin | PL |

ECLASS

| ECLASS-13.0 | 27250304 |

ETIM

| ETIM 9.0 | EC002555 |

UNSPSC

| UNSPSC 21.0 | 20122000 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

Note: Applying some accessories below might limit this product.

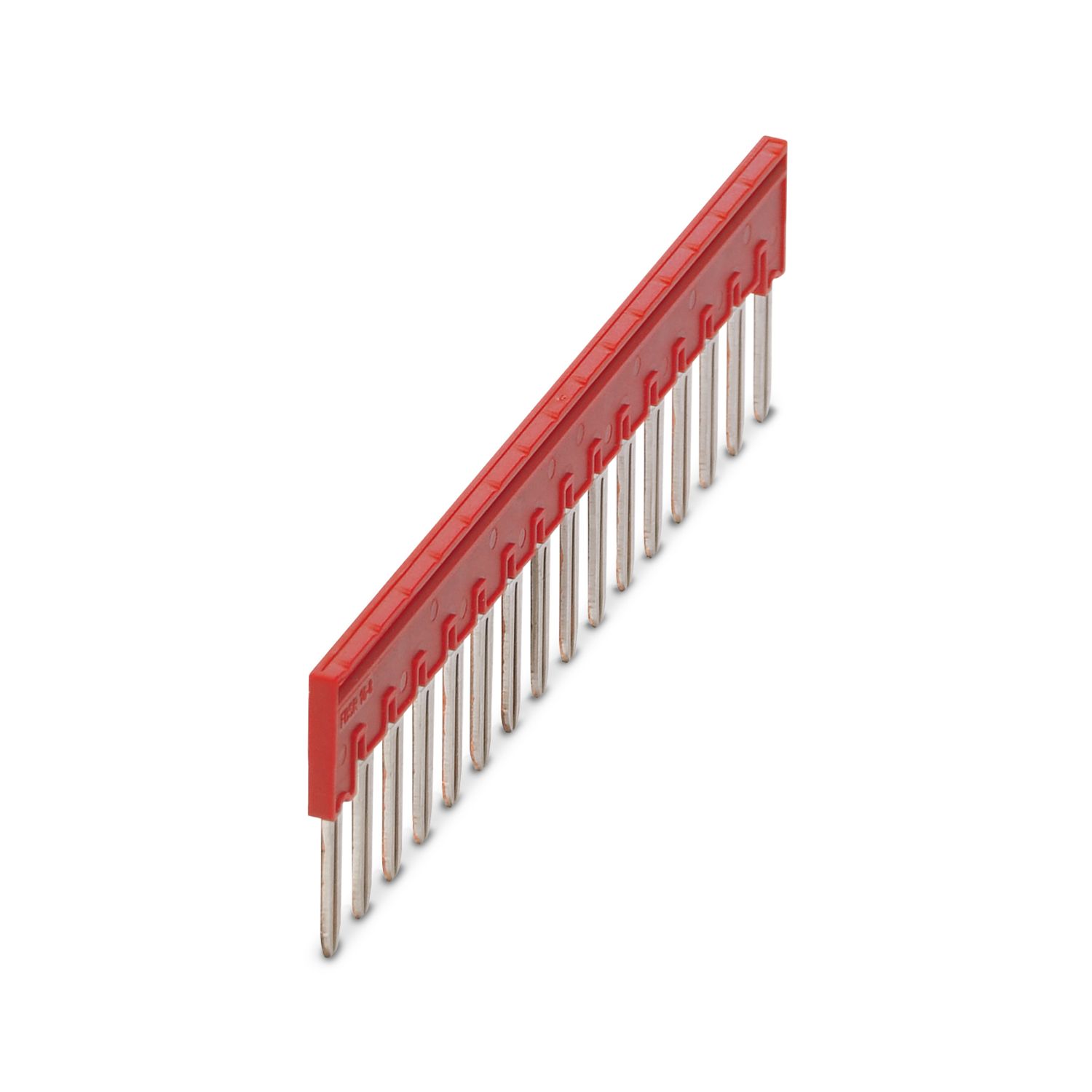

-

-

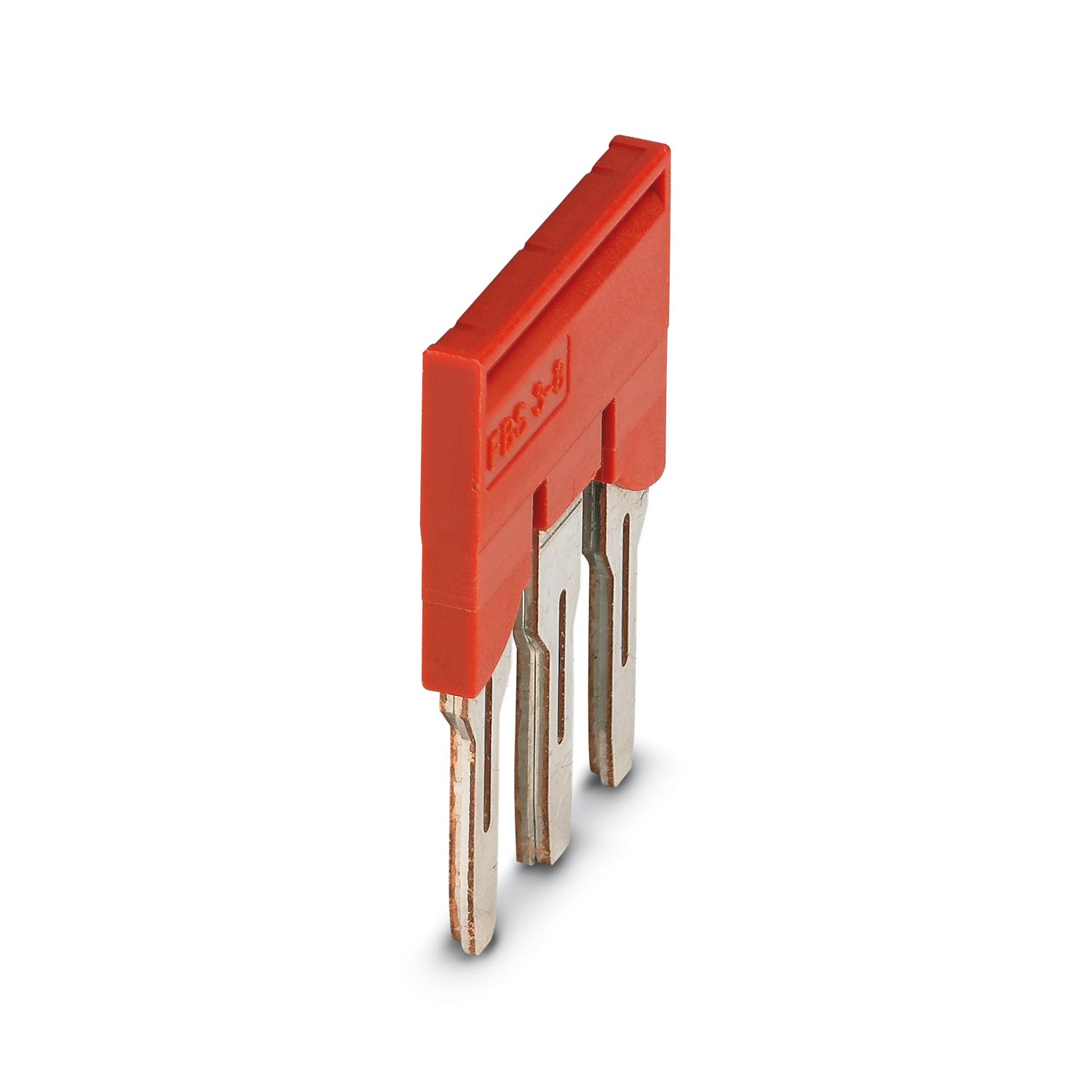

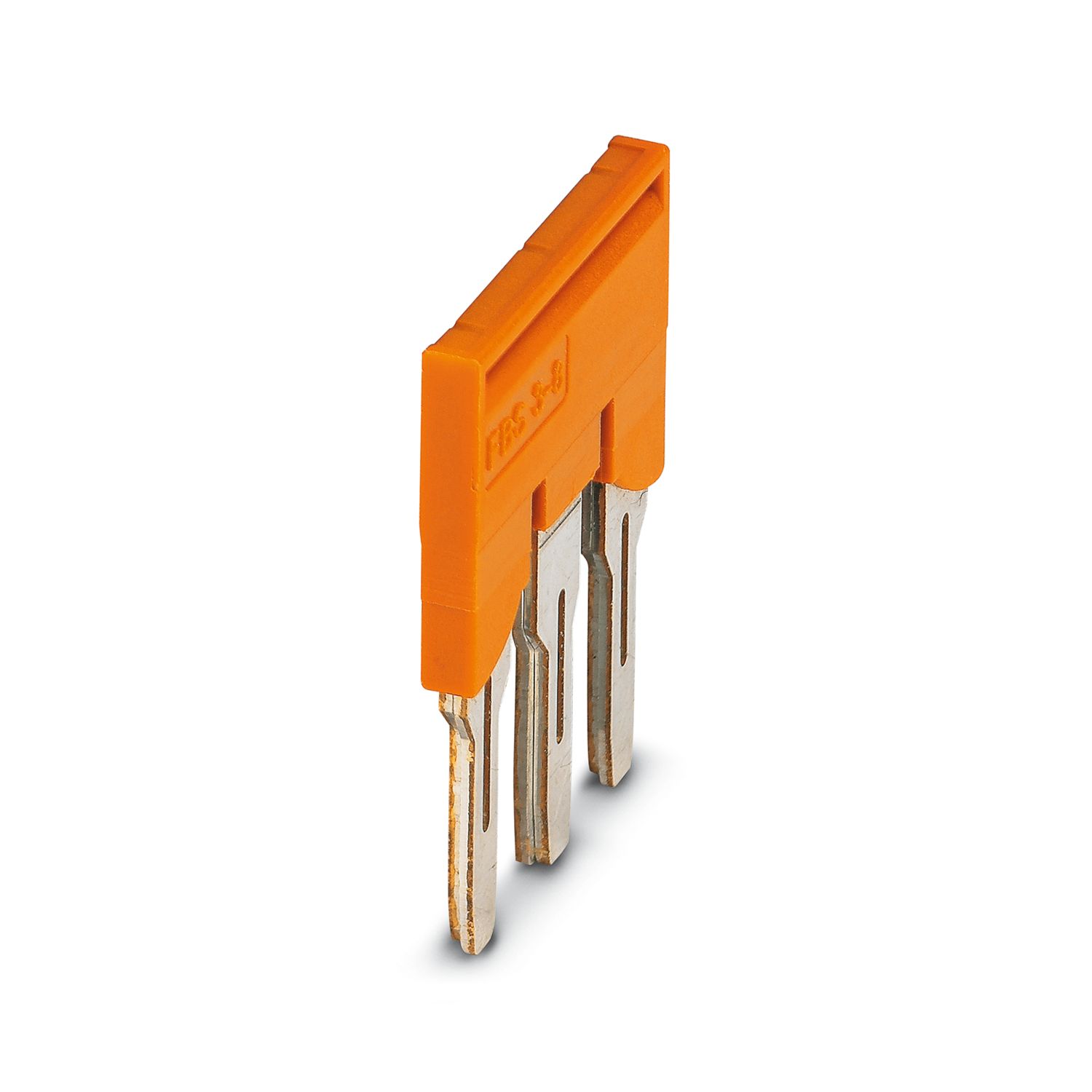

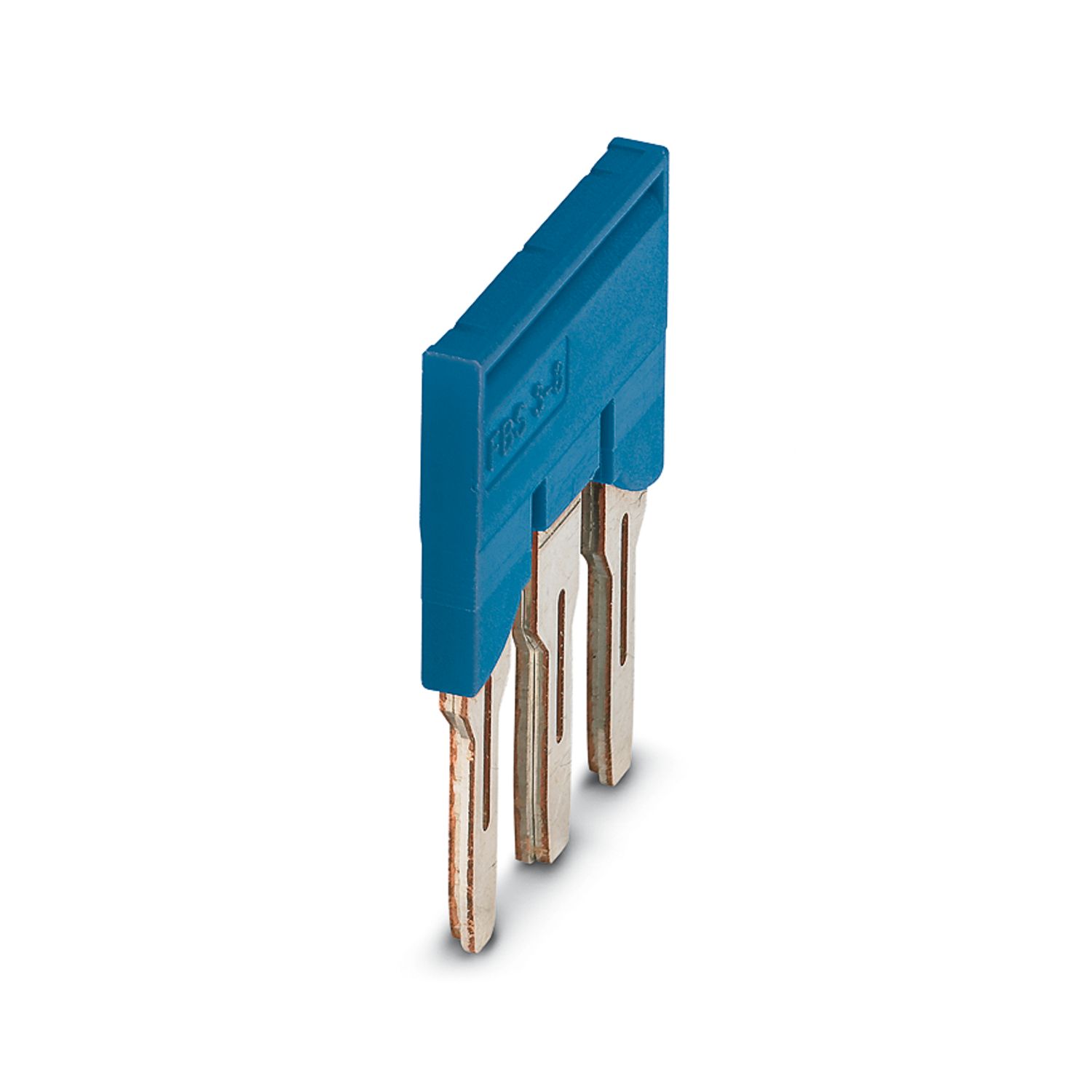

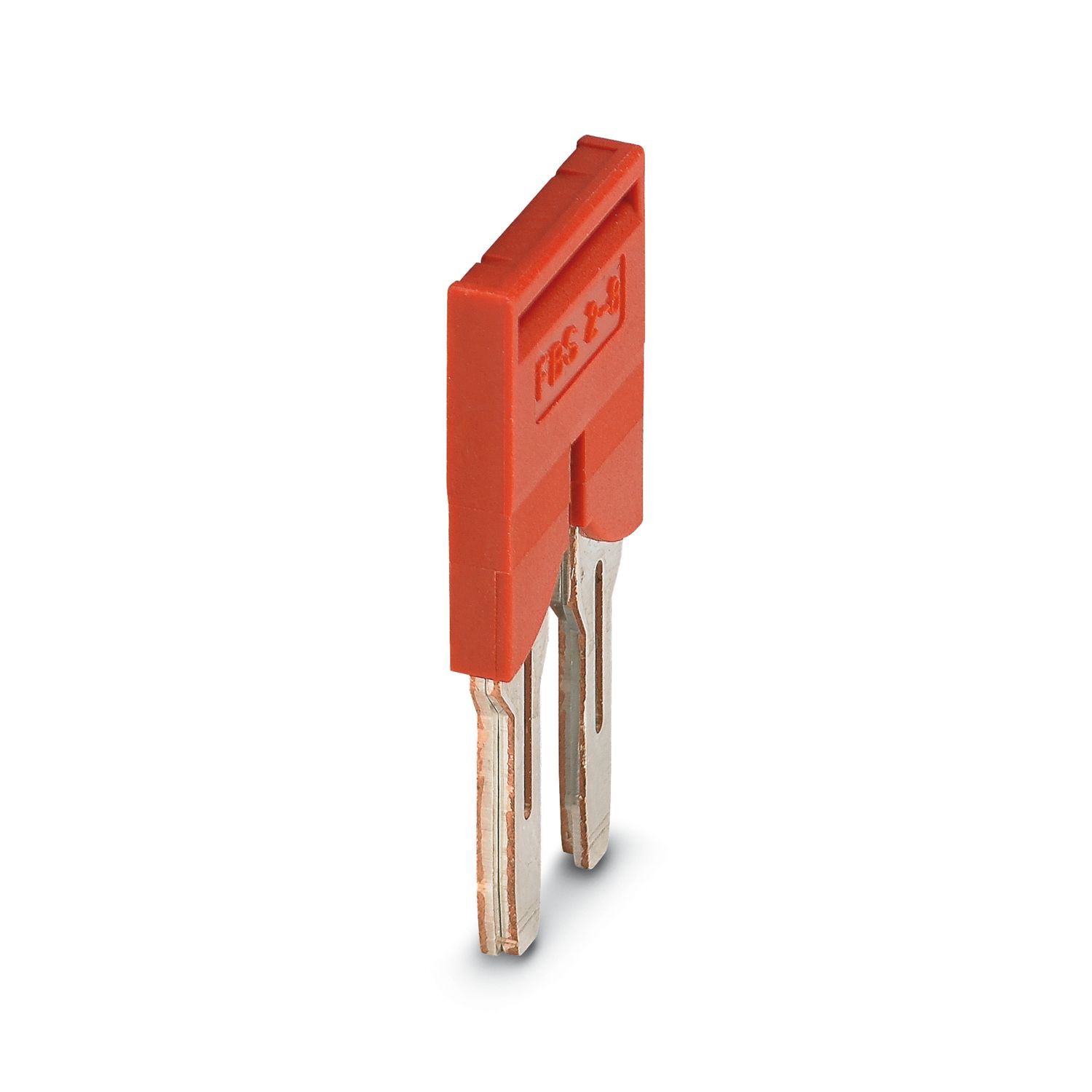

FBS 3-8 - Plug-in bridge 3030297

-

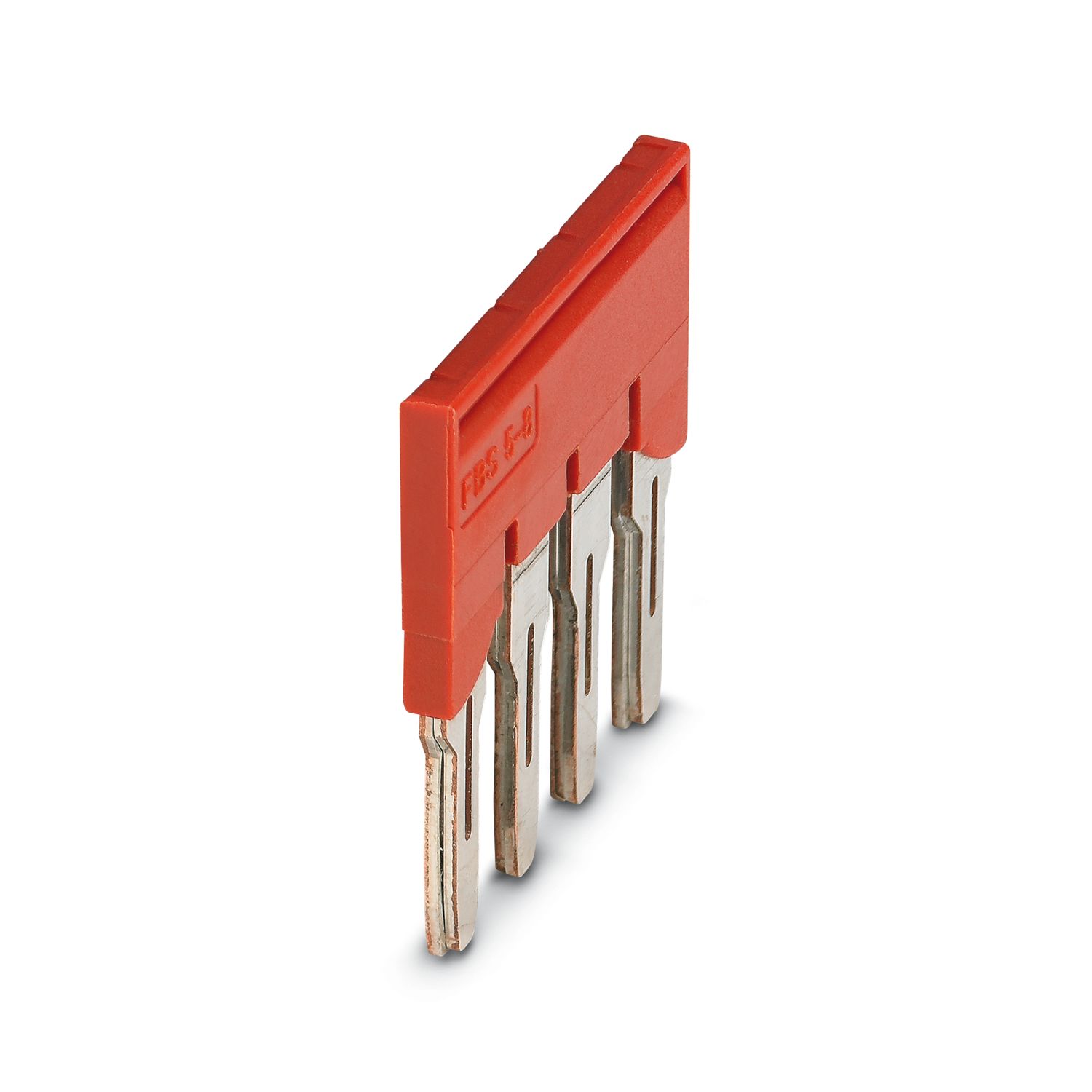

FBS 4-8 - Plug-in bridge 3030307

-

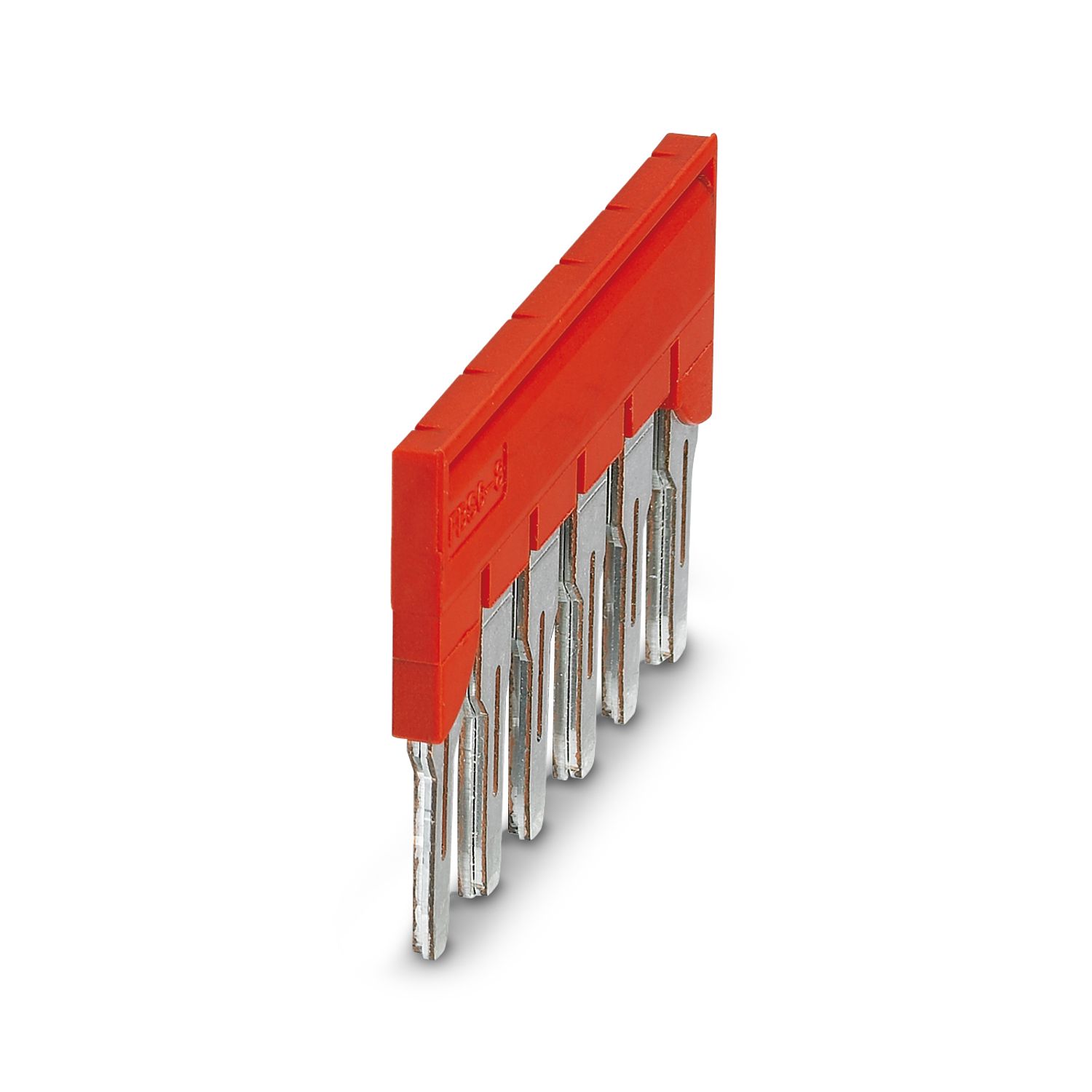

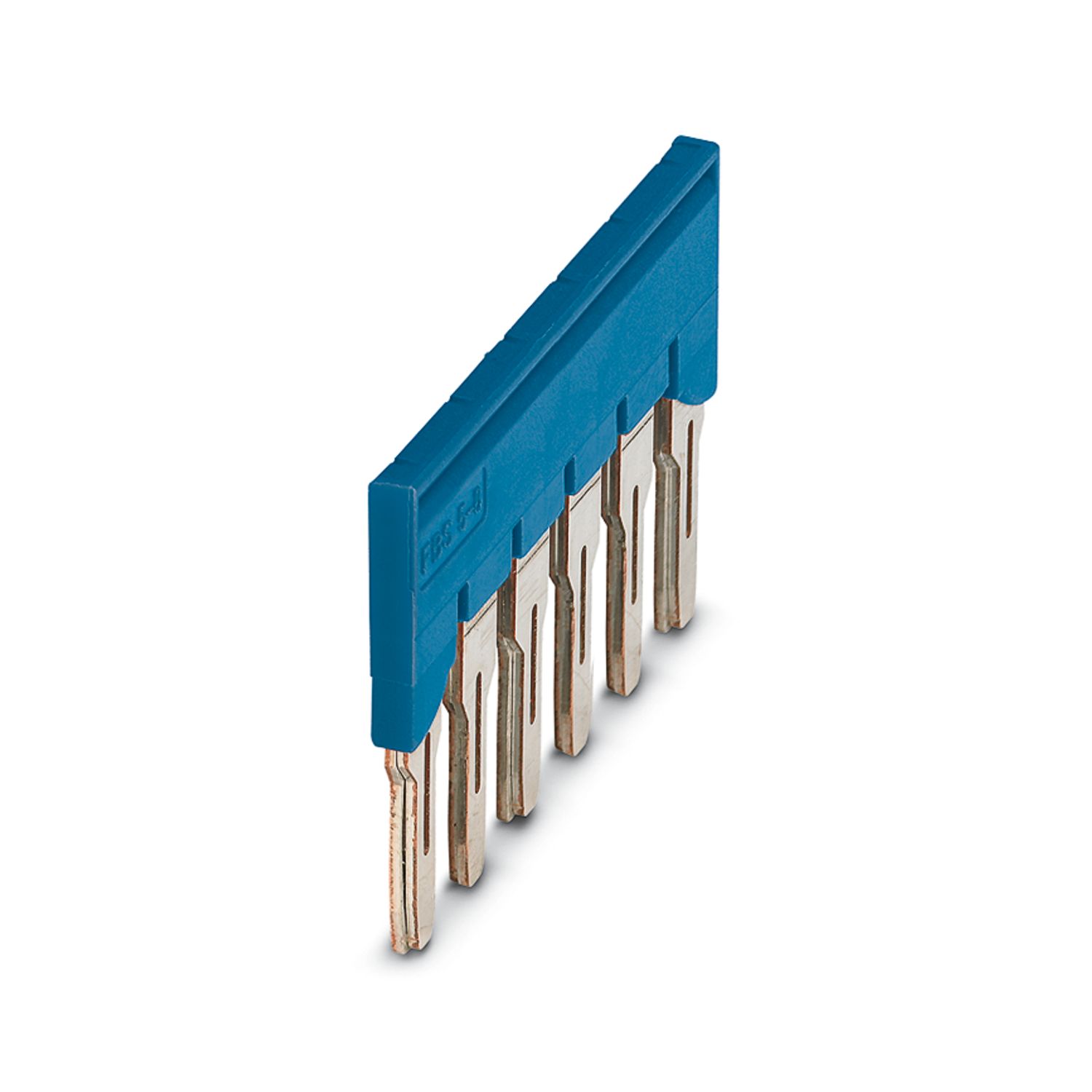

FBS 5-8 - Plug-in bridge 3030310

-

FBS 6-8 - Plug-in bridge 3032470

-

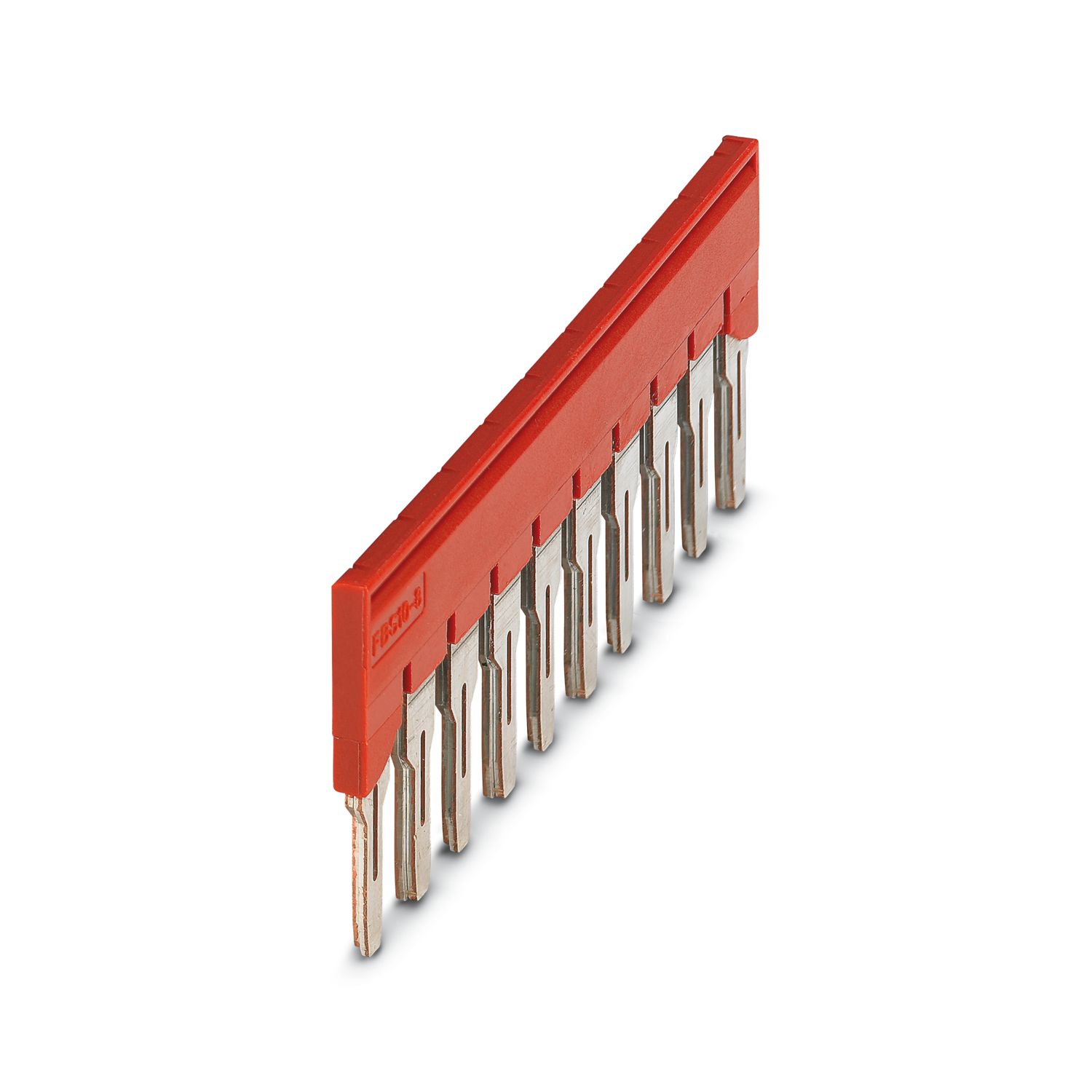

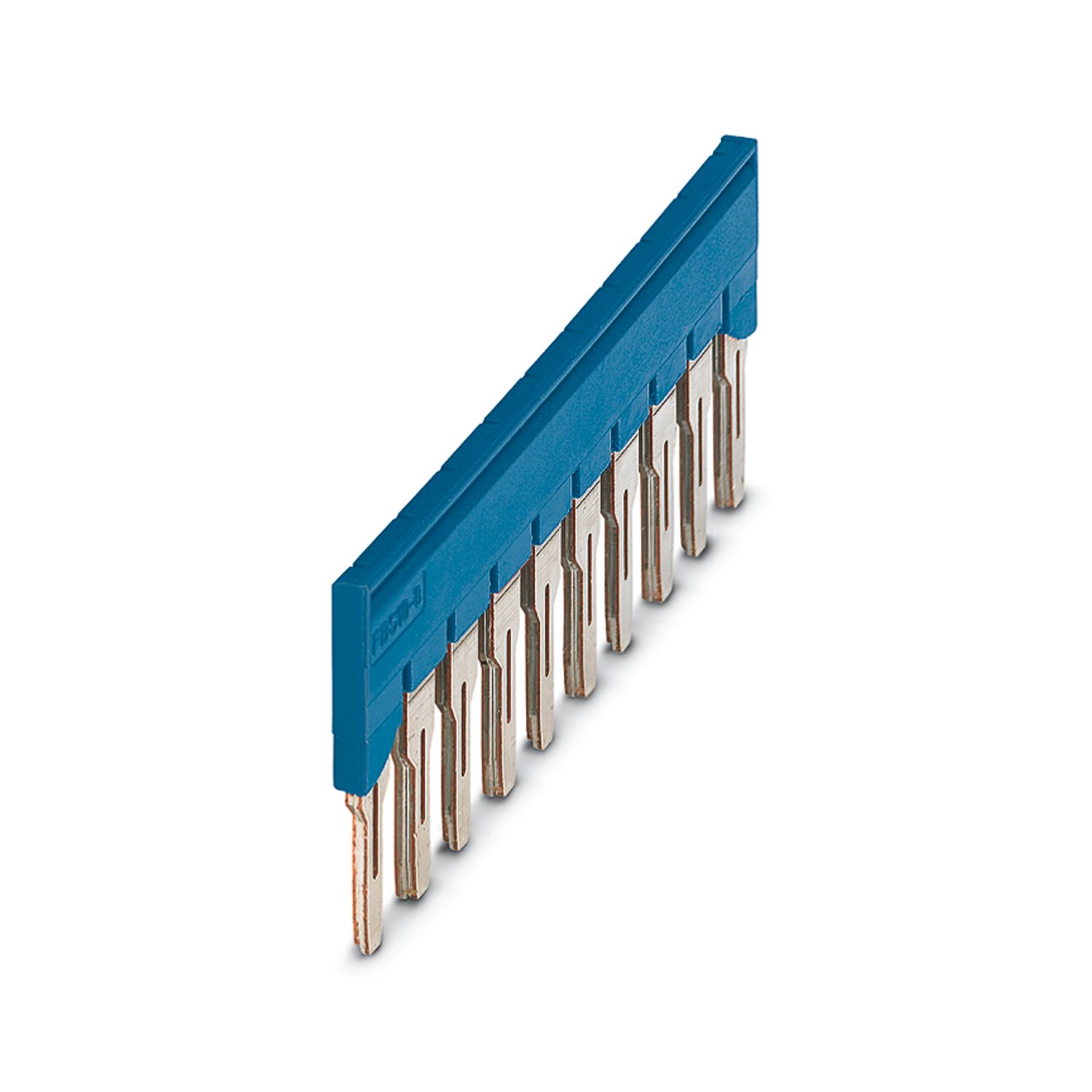

FBS 10-8 - Plug-in bridge 3030323

-

FBSR 16-8 - Plug-in bridge 3033816

-

FBS 1/3-8 - Plug-in bridge 3032363

-

FBS 1/4-8 - Plug-in bridge 3032376

-

FBS 1/3/5-8 - Plug-in bridge 3032389

-

FBS 1/4/7/10-8 - Plug-in bridge 3032402

-

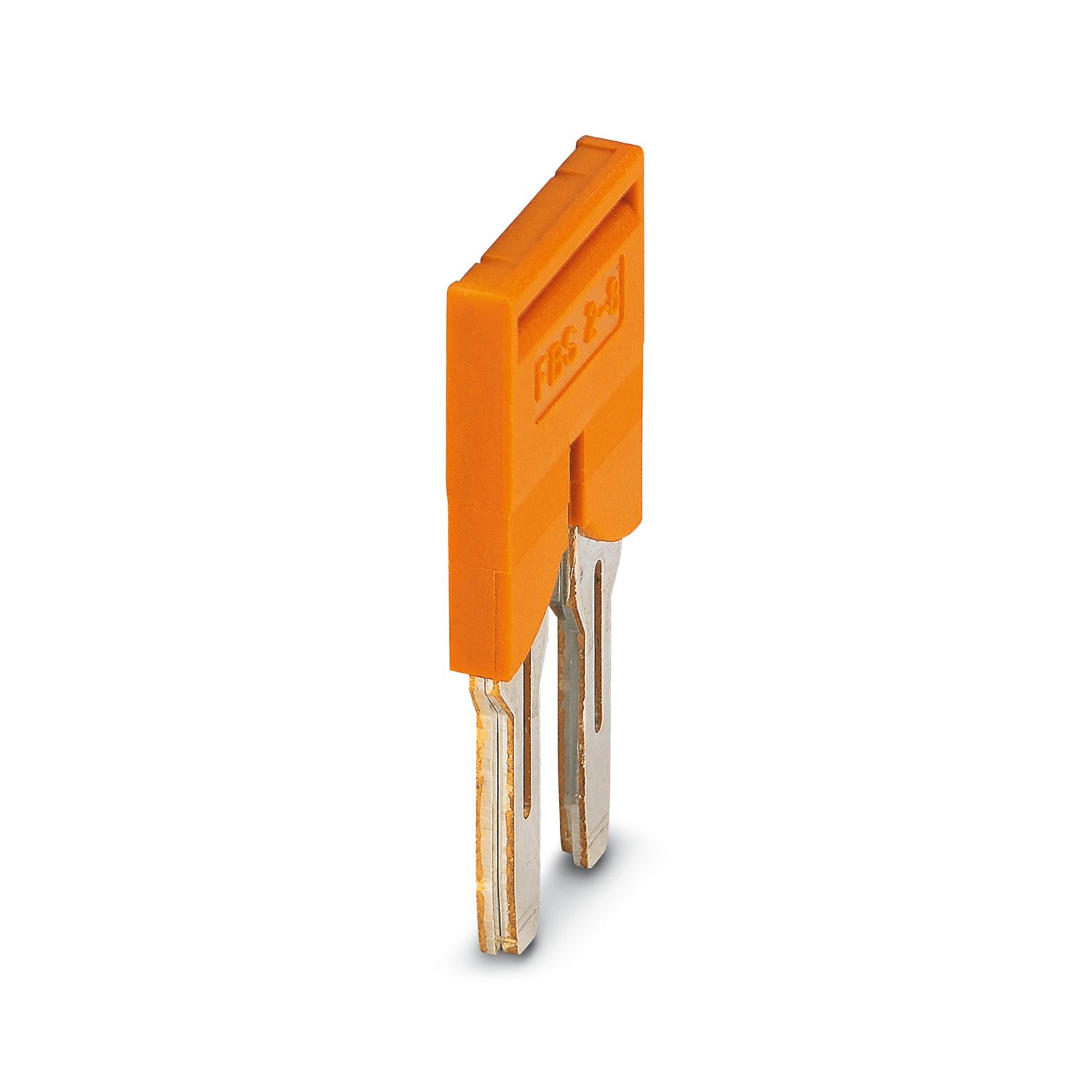

FBS 2-8 CT - Plug-in bridge 3033830

-

FBS 3-8 CT - Plug-in bridge 3033831

-

FBS 4-8 CT - Plug-in bridge 3033832

-

FBS 10-8 CT - Plug-in bridge 3033833

-

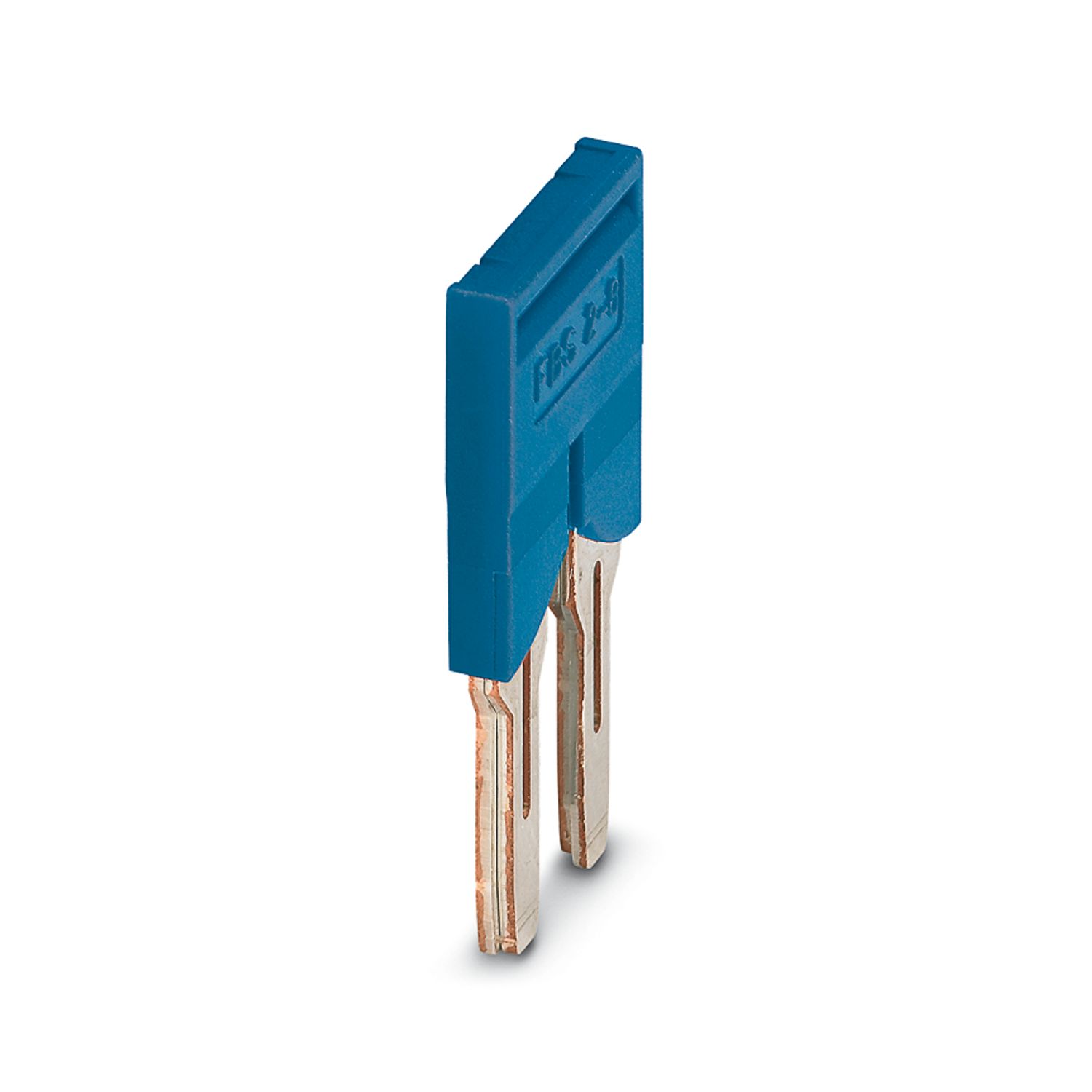

FBS 2-8 BU - Plug-in bridge 3032567

-

FBS 3-8 BU - Plug-in bridge 3032570

-

FBS 4-8 BU - Plug-in bridge 3032583

-

FBS 5-8 BU - Plug-in bridge 3032596

-

FBS 6-8 BU - Plug-in bridge 3032677

-

FBS 10-8 BU - Plug-in bridge 3032606

-

FTPR-2/7 - Test plug 3001685

-

FTP-2/7 - Test plug 3001709

-

FBP-2/7 - Blind plug 3069878

-

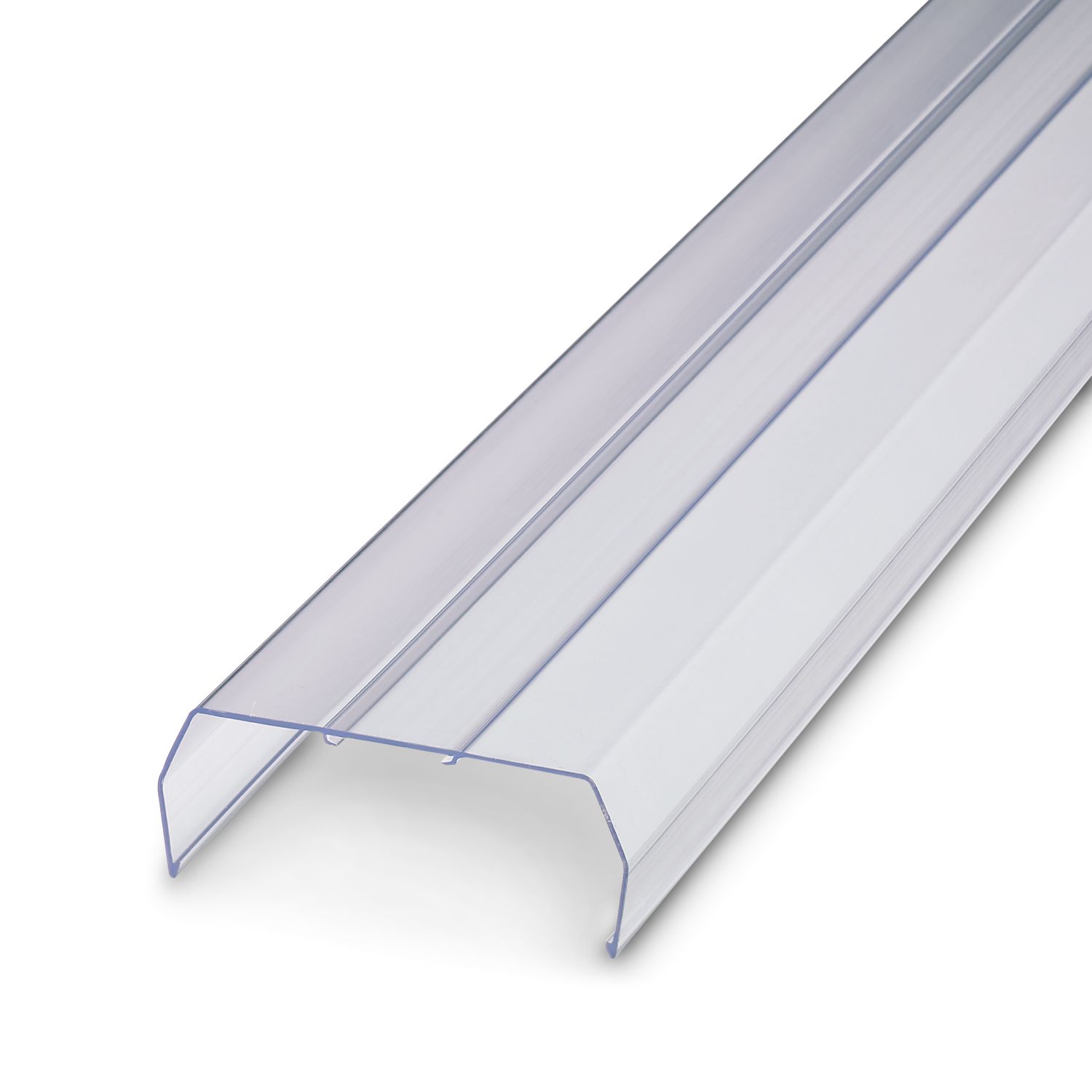

AP-ME METER - Cover profile 3034361

-

APH-ME - Cover profile carrier 3034374

-

APT-ME - Cover profile carrier 3034358

-

PC-UTWE-TRI - Coding profile 3069897

-

FTP-2/2 SERVICE - Test plug 3069464

-

FTP-2/3 SERVICE - Test plug 3069465

-

FTP-2/1 SERVICE 0R1 - Test plug 3069466

-

FTP-2/4 SERVICE - Test plug 3069468

-

FTP-2/1 SERVICE - Test plug 3069469

-

PAI-4-N GY - Test adapter 3032871

-

PAI-4-FIX BU - Test adapter 3032729

-

PAI-4-FIX OG - Test adapter 3034455

-

PAI-4-FIX YE - Test adapter 3032745

-

PAI-4-FIX RD - Test adapter 3032732

-

PAI-4-FIX GN - Test adapter 3032758

-

PAI-4-FIX BK - Test adapter 3032774

-

PAI-4-FIX GY - Test adapter 3032790

-

PAI-4-FIX VT - Test adapter 3032761

-

PAI-4-FIX BN - Test adapter 3032787

-

PAI-4-FIX WH - Test adapter 3032797

-

PAIS-4-FIX GY - Test adapter 3032791

-

PAIS-4-FIX BK - Test adapter 3032792

-

PAIS-4-FIX RD - Test adapter 3032793

-

PAIS-4-FIX BU - Test adapter 3032798

-

PAIS-4-FIX YE - Test adapter 3032799

-

PAIS-4-FIX GN - Test adapter 3032801

-

PAIS-4-FIX VT - Test adapter 3032802

-

PSBJ-URTK 6 FARBLOS - Test plug strip 3026450

-

PSBJ-URTK 6 RD - Test plug strip 3026719

-

PSBJ-URTK 6 BU - Test plug strip 3026434

-

PSBJ-URTK 6 YE - Test plug strip 3026405

-

PSBJ-URTK 6 GN - Test plug strip 3026418

-

PSBJ-URTK 6 VT - Test plug strip 3026421

-

PSBJ-URTK 6 GY - Test plug strip 3026612

-

PSBJ-URTK 6 BK - Test plug strip 3026447

-

PSBJ-URTK 6 BN - Test plug strip 3026971

-

PSBJ-URTK 6 WH - Test plug strip 3026448

-

ZB 8:UNBEDRUCKT - Zack marker strip 1052002

-

ZB 8 CUS - Zack marker strip 0825011

-

UC-TM 8 - Marker for terminal blocks 0818072

-

UC-TM 8 CUS - Marker for terminal blocks 0824597

-

UCT-TM 8 - Marker for terminal blocks 0828740

-

UCT-TM 8 CUS - Marker for terminal blocks 0829616

-

ZB 8,LGS:FORTL.ZAHLEN - Zack marker strip 1052015

-

ZB 8,QR:FORTL.ZAHLEN - Zack marker strip 1052028

-

ZB 8,LGS:L1-N,PE - Marker for terminal blocks 1052413

-

TMT (EX9,5)R - Marker for terminal blocks 0828295

-

US-TM 100 - Marker for terminal blocks 0829255

-

SZF 2-0,8X4,0 - Screwdriver 1204520

Your advantages

Cost-effective, thanks to the tailored, modular design and use of standardized CLIPLINE complete accessories

Space saving, thanks to compact, modular test terminal strips

The integrated, robust switch contact is designed for the most stringent demands, and the use of high-quality materials ensures the transmission of signal currents, even after multiple actuations

Maximum safety with leading and automatic transformer short circuit

PHOENIX CONTACT

586 Fulling Mill Road, Middletown, PA 17057