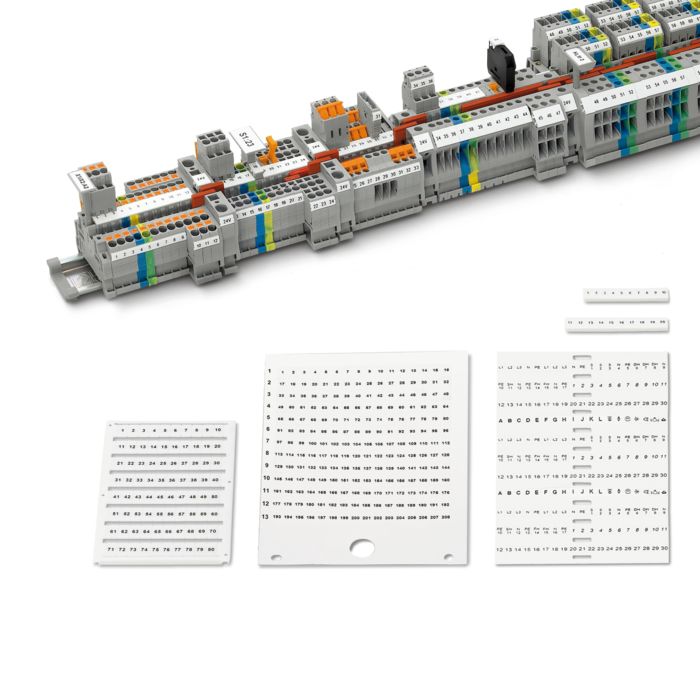

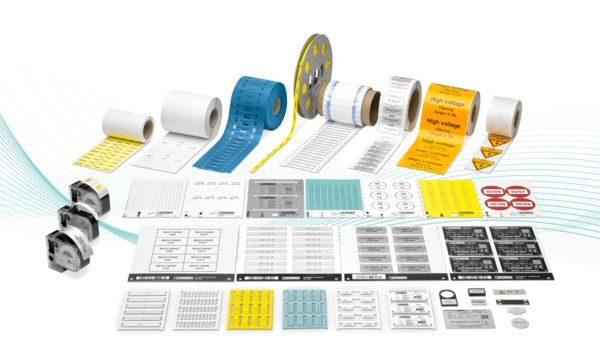

Marker for terminal blocks, Sheet, white, unmarked, can be labeled with: BLUEMARK E.CARD, BLUEMARK ID COLOR, BLUEMARK ID, BLUEMARK CLED, THERMOMARK PRIME 2.0, THERMOMARK PRIME, THERMOMARK CARD 2.0, THERMOMARK CARD, TOPMARK NEO, TOPMARK LASER, mounting type: latching, for terminal block width: 6.2 mm, Number of individual labels: 60, text field height: 10.5 mm, text field width: 5.6 mm