Increase your system availability using our control solution with multicore processor. With the elimination of a separate data processing controller for condition systems, you reduce your hardware costs.

Wind turbine generators are subjected to extreme weather conditions. Unforeseeable grid fluctuations also present challenges when it comes to reliable power generation. Efficient system operation is possible thanks to intelligent automation solutions for wind turbine generators and entire wind farms. This results in continuous energy production while simultaneously ensuring the safety of wind turbine generators. Different requirements for different system types and regions require flexible solutions that can be adapted to the specific project.

Phoenix Contact provides intelligent solutions which can be used to efficiently automate sub-applications, the complete wind turbine generator (WTG), all the way to a wind farm. Phoenix Contact control and software solutions allow you to stay competitive and respond flexibly to dynamically changing circumstances.

We will be happy to consult with you to find the ideal solution together for the automation of your wind turbine generators.

Increase your system availability using our control solution with multicore processor. With the elimination of a separate data processing controller for condition systems, you reduce your hardware costs.

Model your wind turbine generator in Matlab Simulink and perform diagnostics on your models, including debugging, without a Matlab license on our modular software platform.

This software platform speeds up your engineering process thanks to the reusability of user-specific automation modules and object-oriented programming.

The dashboards in the Time Series Data Service of the Proficloud.io IIoT platform from Phoenix Contact are a comprehensive, cloud-based solution for monitoring wind turbine generators. You can check the condition of your wind turbine generators online at any time. You can directly take the necessary measures to prevent damage.

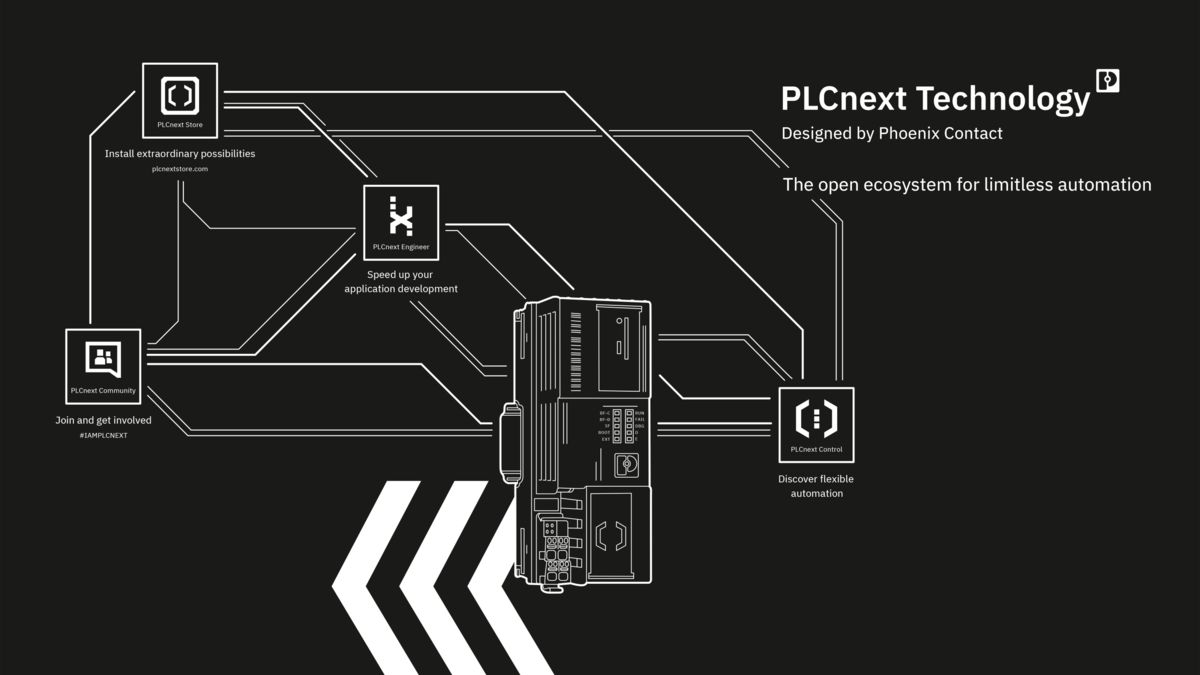

Our solutions are based on PLCnext Technology, the ecosystem for industrial automation consisting of open hardware, modular engineering software, a global community, and a digital software marketplace. PLCnext Technology offers a comprehensive, coordinated portfolio, thus enabling quick and reliable engineering. This technology also allows easy adaptation to the individual requirements of operators, thanks to the integration of open source software, apps, and future technologies. You can implement new IoT-based business models through direct connection to cloud-based services and databases. With PLCnext Technology, you can easily integrate applications developed in high-level languages into your overall system. Individual modules can even be updated or maintained during operation. You determine the core on which the program sequences are run, and which task they are synchronized with.

Feel free to contact us. We will consult with you to find the ideal solution together.