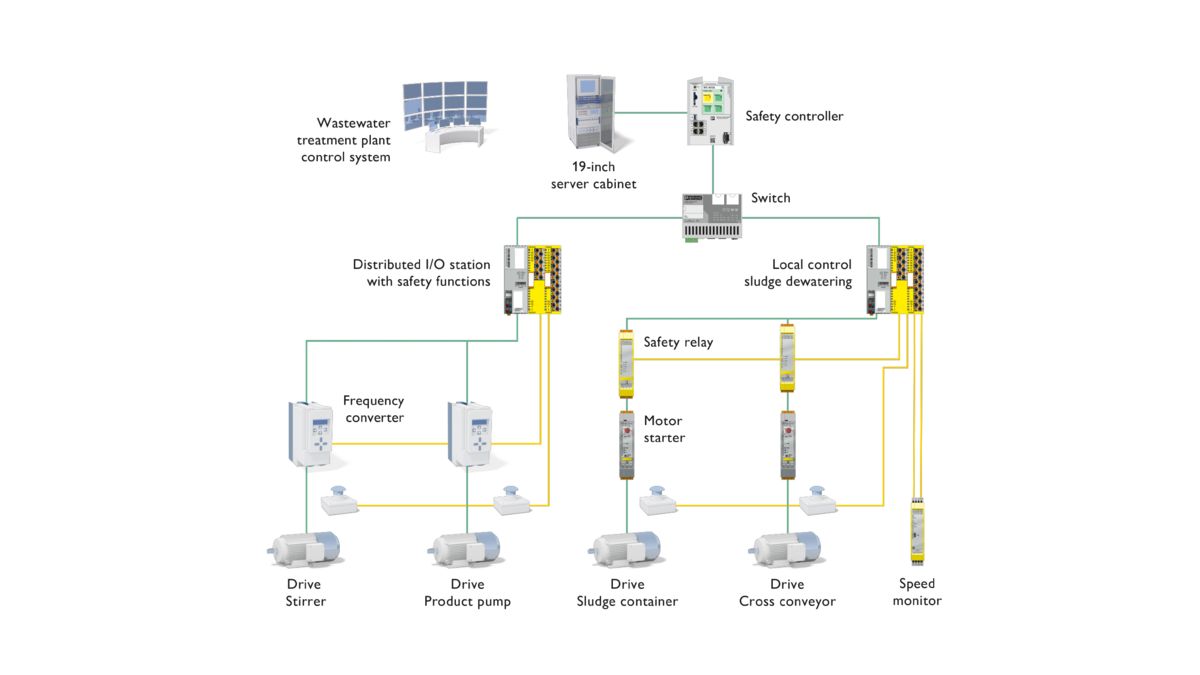

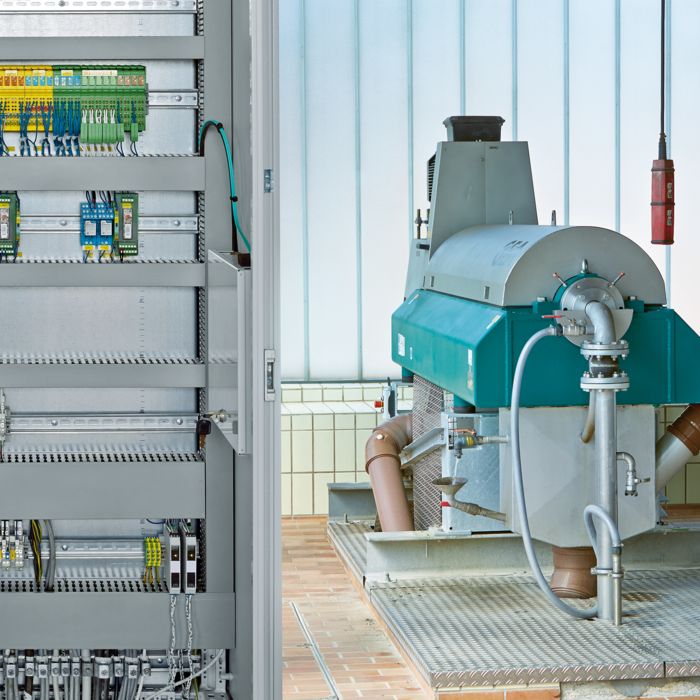

Saving potentials of the sewage sludge plant can be identified by acquiring and storing energy data and analyzing the energy situation. Our current measuring devices are intended for this purpose, which are designed to collect the relevant measured values and transmit them to the control room. Information on the efficiency of the process is transmitted through common interfaces such as Modbus, PROFIBUS, and PROFINET.