Leakage monitoring Implement continuous monitoring of your pipeline with our solutions for time-synchronous data acquisition and transmission.

The challenge

Identifying and reducing leaks

Pipeline leakages can have serious consequences. The causes are not only wear and tear, but also unauthorized access to the product, such as oil, hydrogen, ammonia, or methanol, transported through the pipeline. Sensor stations positioned along the pipeline at distances of 50 km or more register any problems that occur. But it can take time to find and fix the leak. To curb personal injury, property damage, and environmental damage, and to comply with legal requirements, pipelines therefore require high-performance monitoring solutions.

The solution

Cooperation for monitoring leaks in pipelines

Together with Krohne Messtechnik, we have developed a solution for monitoring pipelines. The solution can be used for a wide range of media such as oil and gas, hydrogen, ammonia, or methanol.

PipePatrol offers a total package of products, solutions, and services for comprehensive pipeline management. Operational, safety, and environmental constraints as well as legislative requirements are taken into account.

Transmission of necessary condition data

Reliable data transmission from the field devices is the foundation for solid decisions in the control room.The recorded flow, pressure, and temperature data are time-stamped precisely at the various measuring stations and then transmitted to the control system. The particularly robust components ensure reliable data transmission over the corresponding ranges even under harsh ambient conditions with temperature fluctuations.

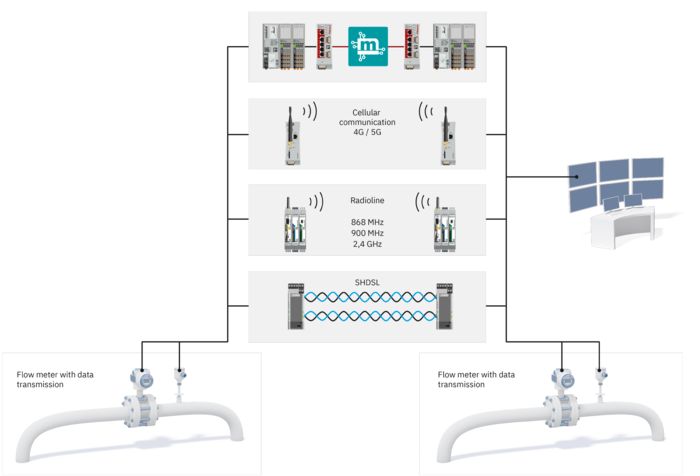

The transmission options, such as secured Internet connections via VPN tunnels and SHDSL, cellular communication, Radioline, and WLAN connections, are adapted to the local conditions in each case and ensure optimum data transmission.

Connection of existing and new sensors

Based on our PLCnext Technology ecosystem, you can connect and use any sensors already in the field. A wide range of intrinsically safe and non-intrinsically safe I/O modules are available for this.

Install new sensors on the pipeline to increase accuracy. This will be coordinated with our partner Krohne and you.

Communication solutions for any infrastructure

Regardless of the area in which the pipeline is used, the discharge of hazardous materials is always a particular challenge for companies. We offer versatile solutions for the automatic detection of leakages. The rapid-response systems are designed for different materials and diameters. Various communication systems provide the basis for tailored communication ranges.

Your advantages

- Uniform controller times, thanks to time synchronization via the NTP server service of the mGuard security router

- Different transmission media for flexible data transmission adapted to your system situation

- Connection of remote system parts, with secure transmission via the Internet

Contact person | Bastian Engel

Products

Still haven’t found the right product?

Feel free to contact us. We will consult with you to find the ideal solution together.