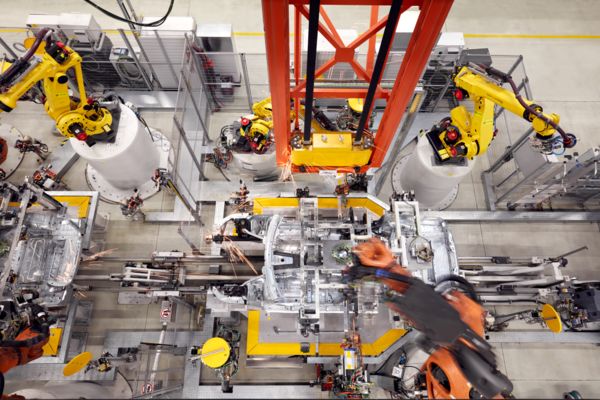

DC in production has benefits A pilot system in the Bavarian town of Dingolfing, Germany, demonstrates how DC technology can also be successfully used in automotive production.

The challenge Driving the energy transition with DC grids in production

Growing demands on sustainability, carbon neutrality, and the careful use of resources are increasingly becoming the focus of an energy transition in production. Particularly in the automotive industry, there are many production steps that have enormous energy requirements.

DC technology provides an opportunity to use renewable energies efficiently and to conserve energy and material resources in the best possible way.

In industry, a large number of loads operate on a DC intermediate circuit via frequency converters. In a DC grid, the loss-inducing conversion between AC and DC for all these loads can be dispensed with. In addition, renewable energies such as photovoltaics and storage systems can be integrated into a DC grid much more efficiently. The energy recovery from braking energy via recuperation is another aspect that makes DC grids interesting for industrial production.

The BMW Group came upon the idea of establishing a DC grid at a very early stage.

Even if the approach of a DC power supply is not fundamentally new, implementing an industrial DC grid in the production environment requires some special features and overcoming some technical hurdles.

Thanks to many years of cooperative collaboration, Phoenix Contact has been able to support the BMW project team with products and solutions for planning and configuration work.

The solution How a DC grid can be set up in the automotive industry

In 2016, the BMW Group plant in Dingolfing, Germany, gave the green light to research the use of direct current in a production cell. Like the BMW Group, Phoenix Contact is a member of the Open Direct Current Alliance (ODCA) and has been committed to establishing DC technology for many years. With its existing solution portfolio, Phoenix Contact was able to provide quick support in setting up the DC grid.

High-performance 19" modules

In order to set up DC infrastructure in a production environment, the public AC grid must first be converted into a DC grid. The powerful power supplies for rack mounting from Phoenix Contact make this is possible without any problems.

The modules can be connected to a total power of up to 1.5 MW and thus ensure a high degree of flexibility. However, the scope of application for the modules is also much broader. The devices with a 19" design can connect the various DC subnetworks, such as the photovoltaic system, the lighting, and the DC charging infrastructure, to the higher-level DC bus. Thanks to the wide output voltage range of 30 V DC to 1000 V DC, it is also possible to gradually ramp up the entire DC grid. The performance parameters of the modules are easy to parameterize via the PLC Next platform from Phoenix Contact. In the future, this will enable the individual DC sectors to be coupled together in a grid-friendly way.

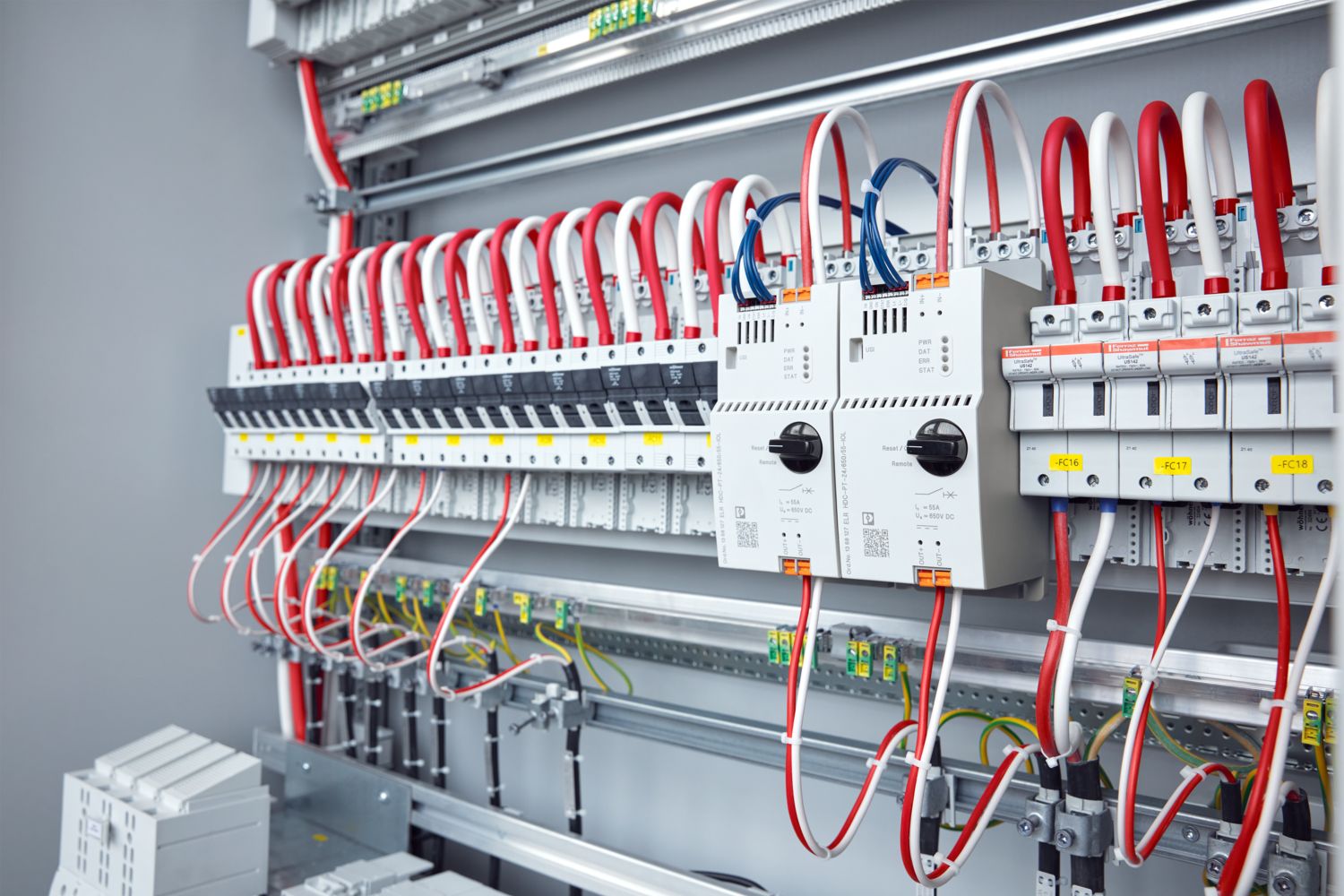

Power supplies for DC grids

The QUINT POWER DIN rail power supplies can be used wherever a 24 V DC auxiliary supply voltage is required in a DC grid. They impress with their wide DC input range, which extends from 450 V DC to 900 V DC. In the performance class from 240 W to 960 W, individual loads can be supplied. Switching, protecting, and precharging DC sectors in an existing DC infrastructure also pose technical challenges, and Phoenix Contact already has the perfect solution.

Multifunctional DC circuit breakers

Switching, protecting, and precharging DC sectors in an existing DC infrastructure also pose technical challenges, and Phoenix Contact already has the perfect solution. The CONTACTRON ELR HDC DC circuit breaker was designed specifically for these applications. It has a precharging function to raise capacitive loads, in particular to a common voltage, and thus prevent current and voltage peaks during the switching process. The device also monitors voltage and current during operation and has a three-stage shutdown function in the event of overcurrent – including very fast shutdown times in the event of a short circuit. The operators can easily set the essential parameters via the USB interface. The switch also features network capability with an IO-Link interface.

Safe DC connectors

A decisive difference between direct and alternating current is the electric arc during disconnection processes under load. In AC applications, the current and voltage oscillate. This means that zero crossings with pole reversal occur 100 times per second. This is not the case in DC applications, so a possible electric arc is not automatically extinguished. Damage to contacts and housings tends to be more frequent in a DC supply system configuration, and there is a greater risk to the operators. The ArcZero connector is the only connector of its kind that actively extinguishes the DC electric arc. It works with an active intelligent electronic controller, which ensures a high number of insertion cycles. This unique technological approach has enabled frequent and safe plugging and unplugging under load without electric arcs in DC grids.

The solutions from Phoenix Contact are also used at the BMW Group plant in Dingolfing, Germany. With this approach, we are pioneering the breakthrough of DC grids.

Advantages of DC grids in production The benefits of DC in production

-

Significantly increased energy efficiency compared to AC systems

-

Utilization of the recuperation energy within the robot test cells reduces energy consumption

-

Raw material savings with lower conductor cross-sections and fewer cables

Contact

Let’s shape a more sustainable future together by developing direct DC grids