More control cabinets with efficiency TOBOL, a building automation company and switchgear manufacturer, is using the consulting services of Phoenix Contact to position itself ready for the future of switchgear manufacturing.

Brief summary

Power grids worldwide will need to be massively extended – and millions of additional control cabinets built – if we are to electrify all sectors of society and industry. Digitalization and ongoing optimization not only makes it possible to produce more quickly and more efficiently, but also to increase quality.

Project Manager Henning Rey works at Phoenix Contact and advises control cabinet building companies on process optimization in accordance with lean principles

Process optimization in accordance with lean principles

A production hall in Leinefelde in Thuringia, Germany: as if on a playing field, black marking lines run across the glossy hall floor. The walking paths are clear, and skilled workers and trained employees focus on different process steps in switchgear manufacturing in each marked area. Everything is airy and tidy.

TOBOL GmbH manufactures switchgear of the highest quality here. With its new production hall in Leinefelde, it has not created a new building shell for old processes, but has restructured its entire switchgear production. With the help of the Phoenix Contact consulting services, production is carried out here in accordance with the principles of lean management.

“We have already begun to integrate our cooperative into the existing location”, reports Tobias Funke, General Manager of TOBOL GmbH. “The Phoenix Contact consulting services have helped us to improve our digital processes, become leaner, and respond more quickly”. The process that this company has undergone and is still undergoing is still one that a large number of control cabinet builders still has to go through.

At the Cardboard Engineering Workshop, employees design their new workstations and tool carts on a 1:1 scale with cardboard models

Ready for the All Electric Society

The fact that companies in the industry are increasingly dealing with subjects such as increasing efficiency and digitalization is not only due to the shortage of skilled workers. Power distribution grids must be extended significantly so that they can supply all sectors of society and industry with energy from renewable sources. “The demand for control cabinets will increase massively in the coming years due to the increasing electrification, networking, and automation”, says Henning Rey. As a project manager and consultant, he has dedicated himself to more efficient processes in control cabinet building.

The challenges of the future are formidable: it is estimated that the power grids need to be extended by around 20 percent, including the necessary switchgear. Worldwide, around 5.5 million additional control cabinets will have to be built for this alone. Further control cabinets will also be used for applications that will be electrified in the future, for example in e-mobility and building automation.

Nevertheless, consultants such as Henning Rey are often experiencing a certain degree of skepticism when it comes to the introduction of efficiency and digitalization measures. The most common reason is a defensive approach to lean methods for increasing efficiency in traditional production processes. Today, TOBOL is better positioned than ever for such tasks and automated processes. “Now, we can accept orders that were previously not possible, including series orders”, reports General Manager Tobias Funke. But nobody can change such work processes overnight. “First of all, we invited the TOBOL employees to a goal workshop in Blomberg”, says Bernd Naguschewski, Head of the Applications Center for Control Cabinet Building at Phoenix Contact. The next step was a cardboard engineering workshop.

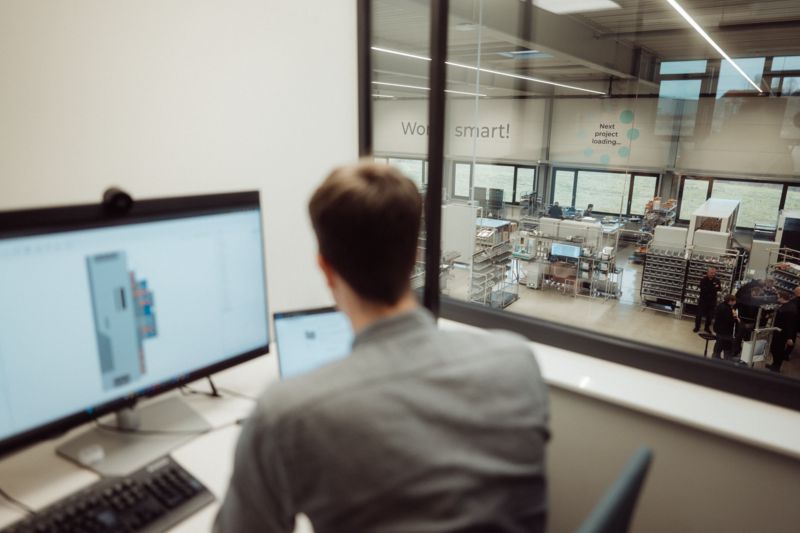

From the offices of the designer engineers, the data goes directly to the production hall and logistics

Planning, play through, optimize

In the past, production was organized by production planners, often without consulting the employees. For the Phoenix Contact consultants, however, it is important that employees are heavily involved in the improvement process right from the start. In cardboard engineering, they design the prototypes of their workstations themselves: “What do the employees need? What are the walking distances? How many tools do they really need at the workstation?”, says Henning Rey, describing the approach. The method makes it possible to model work systems, simulate processes, and analyze processes without incurring costs for real equipment.

Together with his colleagues, production employee Frank Klaus put his heart and soul into the project. “We changed this shelf many times and thought about things together. Then we practiced and played through everything until we were satisfied”. In the past, everyone was constantly walking through the hall. The walking distances were far too long. However, the results of the workshops were not just new material carts, marked walking distances, and a tidy production hall. All materials are now delivered just-in-time to the workstations and displays show the current production status, everything is paperless and digital. Errors, changes, and suggestions for improvement are recorded directly in the system.

From above, design engineers can look directly into the production hall from their offices. From there, circuit diagrams, bills of materials, and layout plans are sent to production and the integrated logistics area, where the orders are picked. “This was also the result of the optimization process: TOBOL has its own logistics area. In other companies, the electrically skilled persons have to search laboriously for their material, which takes up valuable working time”, says Henning Rey.

The wheel of fortune at the end of the morning exchange determines who will present the round for the following day

A little better every day

Every morning at 9:45 a.m., employees from all areas of the hall come together. It is time for the daily update. Today, Ralf Krause, Plant Manager at TOBOL, presents the round. This shop floor management process is also a result of the consultation process. It takes up just 10 minutes a day, but it is worthwhile. “Thanks to the shop floor management process, we exchange ideas effectively – about everything that works in production, but also about what goes wrong”, reports Krause. In the past, employees would approach him with problems throughout the entire day, but now he is here at 9:55 a.m. with everyone. “Then I meet with the General Manager at the coffee machine to discuss everything”.

Target-oriented working instead of constant monitoring: Employees enter any errors occurring into the system directly during production work. “Thanks to digitalization, we have clear transparency, also for the customer. We can provide feedback in good time and not only once the horse has jumped the cart”, says Plant Manager Ralf Krause. General Manager Tobias Funke adds, “Thanks to the lean production methods, we have become much faster and more efficient”. Both emphasize that the cooperation with Phoenix Contact always ran on an equal footing in partnership and has brought everyone to their goal quickly.

But it is not only the processes that have become faster and more efficient, employee satisfaction has also increased. Production employee Frank Klaus can confirm this. “Getting a new production facility, that is a dream come true. But it only becomes really good when you can help design it yourself: today, our workstations are laid out the way we need them”.

Summary

Our power distribution grids must be extended significantly if we want to be able to electrify all sectors of industry, private life, and society. Millions of control cabinets will be needed in the next decade. Control cabinet building companies also need to focus on the subjects of increasing efficiency, digitalization, and lean processes so that they can play an important role in the realization of the All Electric Society.

Connect with our experts

More posts

Coupling of factory and building

The Emalytics Automation building management system harmonizes data formats and intelligently networks sectors.

Energy storage systems connect sectors

The importance of innovative connection technology for the safe operation of energy storage systems and for the realization of the All Electric Society.

5G campus networks

Industrial application examples for wireless broadband communication.