5G campus networks Industrial application examples for wireless broadband communication.

Brief summary

Low latency as well as high stability and high data transmission rates: these are some of the features that 5G bring. So-called 5G campus networks promise considerable potential for industrial applications. Large chemical companies and combined facilities are exploring these – and discovering, among other things, how 5G can be useful for the operation of automated guided vehicle systems as well as in tank farms and in supply chain management.

5G as a driver of the digital transformation

A look into the past: It has probably rarely been the case that four industry associations were as in agreement as is the case with 5G. In a joint press release in November 2020, the VCI, VDA, VDMA, and ZVEI associations declared a “high interest in industrial 5G campus networks”. In the press release, Martin Schwibach, responsible for Industrial Connectivity & Industrial Mobility at BASF, representing the chemical industry, spoke of 5G campus networks as being an “important prerequisite for driving forward the digital transformation in the chemical industry”. Schwibach is considered one of the driving forces for new technologies in the chemical industry.

It is no secret that BASF, like other chemical companies, has been dealing with 5G cellular technology for some time. As early as 2018, an article in the Wirtschaftswoche magazine illustrated that 5G cellular communication could “turn the logistics world at BASF upside down in the future...”. BASF Manager Matthias Frankhänel demonstrated at the time how a driverless tank transporter “feels” itself through the Ludwigshafen factory premises – always along transponders that are embedded in the ground and closely monitored by video cameras and an employee in a central control room. Frankhänel already knew at the time that “If we use 20 or more vehicles in the future, we will only receive the masses of transferred data with 5G technology”. BASF then built up a test environment for 5G in various areas of application in the production environment.

Cellular networks in their solitary majesty

The company was not alone. As of May 2021, 126 companies and organizations have submitted an application to the German Federal Network Agency for frequency assignment in the range of 3,700 to 3,800 MHz for their local 5G network – including Phoenix Contact. Such a campus network – often in conjunction with an edge cloud – opens up new possibilities for industrial communication within the framework of Industry 4.0. Unlike previous cellular technologies, companies can fully control such networks on their premises, therefore retain sovereignty over their own data, and determine the security and availability of the network. However, they can also install and operate the networks via public operators or other providers, which also enables medium-sized players in the process industry to use them.

The AGVs (automated guided vehicles), which supply the huge BASF plant with raw materials, represent a spectacular, but not the only, possible application for 5G cellular communication in the process industry. Since the driverless vehicles are usually on the move in the non-Ex area, the transmission of the live videos required for monitoring is one of the first potential applications in large chemical plants. For applications where explosion protection plays a role, current protection concepts for industrial communication urgently need to be revised and adapted to the new requirements for avoiding ignition sources.

Emergency shower monitoring can increase the safety of plant personnel by immediately alerting the nearest operational medical station

Potential applications for 5G

It can be assumed that the applications for 5G currently being discussed in the chemical industry will be possible from around 2025. In addition to operating AGVs, these includes numerous applications in production, including the big data transmission typical of Industry 4.0 for monitoring and optimization, for example. They also include safety-critical applications, for example, the signalization that an emergency shower is in use to a rescue team.

With fill level monitoring, deviations of critical system parameters, such as fill levels, temperature, and pressure are detected at an early stage in the communications network

There are many other potential applications within the scope of logistics and supply chain management. For example, gaps in the supply chain can be avoided if, in the context of inventory management, the fill levels of tanks are automatically sent to the suppliers and, where necessary, an order placed. In principle, this can also be done with other communication technologies. However, if – as with Phoenix Contact – a 5G campus network is available, it makes sense to use it for such applications.

Transmission in the opposite direction is also possible: The supplier can send quality information about the current product batch prior to delivery to the processing company, who uses it, for example, for process optimization. There are further options for data forwarding for the purpose of traceability in the production processes, which have long been a must in the pharmaceutical and food industry. Additional quality data collected from intermediate products can be transmitted to the QM control center with little effort using wireless technologies.

Augmented reality provides support during maintenance work

Simplified monitoring with drones

Another case for 5G could be the transmission of video signals as part of the security monitoring of large or difficult-to-access systems – for example, steam crackers, oil platforms, and large tank farms. Drones equipped with thermal imaging cameras, such as those already used by some company fire departments in chemical parks, will be able to take off autonomously in the future from the companies and warehouses to be monitored and forward their video data for evaluation in real time. Hotspots will therefore discovered before a fire breaks out.

5G will also open up opportunities for maintenance teams to optimize their work. For example, within the framework of augmented reality via smart glasses and tablets, two Industry 4.0 applications that have been propagated and implemented in part for a long time. The in-house 5G campus network can be used to provide service personnel with technical instructions and short videos on site in the system at any time. According to the vision, even a mass number of data transfers, caused by an entire team of mobile workers plus some AGV transporters, would no longer lead to bottlenecks.

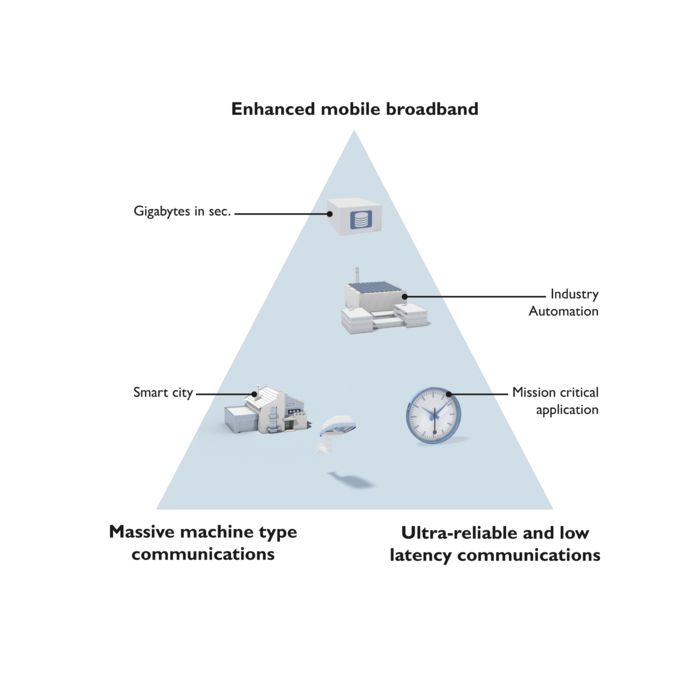

The various characteristics of Industrial 5G can be used depending on application

5G features valuable services

In view of all these potential applications, one feature of 5G technology is particularly important – unlike other mobile phone standards, 5G is a fully-fledged communication infrastructure. It includes valuable services – for example, the ability to assign resources and priorities to the devices different ways. Monitoring critical functions in production operations certainly requires a high degree of reliability during data transmission; the priority here would have to be set to a high level accordingly. However, the data for the condition monitoring of a number of pumps in the course of predictive maintenance is not usually time-critical. The priority would therefore be set to be low.

The required data rates are also rather low. The example of the emergency shower demonstrates that a low data rate does not have to correlate with a low priority. The medical station needs just a single signal to recognize that the emergency shower has been put into use. But this must reach it as quickly as possible. The high data rates required to operate AGVs, on the other hand, come with a lower priority. If things actually become tight on the data highway, the AGVs can simply be parked temporarily at the nearest safe stop.

Looking toward the future

With these options for orchestrating the 5G network so that it covers the needs of very different applications in industrial operations, 5G stands out from all other transmission technologies. So it could one day become the only communication standard – at least in large industrial sites. This is admittedly a dream of the future. The coexistence of various wireless and wire-based connection technologies will probably shape most companies in the process industry for a long time to come. And in the future, many smaller chemical companies will be working completely without 5G. However, 5G will demonstrate its benefits in numerous companies through the applications in intralogistics with the integration of AGVs and drones as well as applications within the scope of condition monitoring and maintenance in just a few years.

Connect with our experts

More posts

Coupling of factory and building

The Emalytics Automation building management system harmonizes data formats and intelligently networks sectors.

Feed-in management 2.0

Phoenix Contact provides a certified solution for photovoltaic systems.

Integral building planning

How integral building planning and digitalization are revolutionizing building construction.