Feed-in management 2.0: power control unit with additional functions Phoenix Contact provides a certified solution for photovoltaic systems.

Brief summary

Grid operators are obligated to feed as much energy from renewable sources into the grid as possible, while not putting the stability of the grid at risk. Power control units – that is, controllers for power generation plants – are used to control and regulate the active and reactive power. However, the certified devices from Phoenix Contact have a lot more features in store, due to the underlying PLCnext Technology.

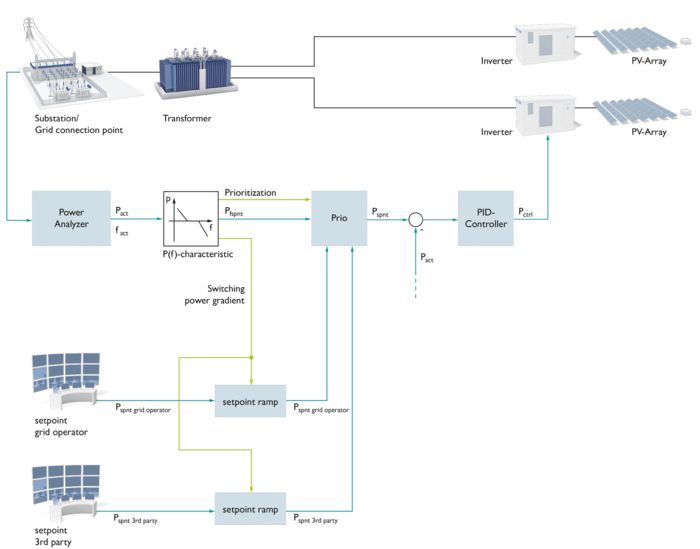

System overview of a photovoltaic system with feed-in management

Power generation and grid quality: a challenge for the energy revolution

According to the German Federal Ministry for Economic Affairs and Energy, renewable energies are the most important source of electricity in Germany. As the central pillar of the energy revolution, its share of electricity consumption is constantly growing: from around 6% in 2000 to 46% in 2022. At the end of 2022, around 2.6 million photovoltaic systems (PV) produced around 66 GW of power as part of the renewable energies. However, the steady increase in installed PV in both the low and medium-voltage grids presents considerable challenges. This is because decentral power generation plants must also make their contribution to ensuring grid quality.

The frequency and voltage are used as the relevant parameters for their evaluation. The mains frequency depends on the active power balance of the grid. If the generators feed more active power into the grid than the loads require, the mains frequency increases. The mains voltage, on the other hand, is influenced by the reactive power balance of the grid. Here, if the demand for reactive power increases, this leads to a reduction of the mains voltage.

Technical and regulatory requirements

Decentral power generation plants are often said to have a significantly negative effect on the power quality. This is mainly due to the fact that external conditions such as the wind and sun, which largely determine the performance of the systems, can neither be controlled nor adequately planned. It is forgotten that these systems already provide the technical prerequisites for stabilizing the mains frequency as well as the mains voltage. If the share of renewable energies in electricity consumption is to increase significantly in the medium term, a massive extension of energy storage systems is clearly necessary.

In addition to power generation, general tasks in power distribution must also be solved. For example, the liberalization of the electricity markets is increasingly accompanied by cross-border power transmission. As a logical consequence, European specifications were adopted in the so-called “Network Code – Requirements for Generators”. This network code describes the rules of the grid connection to which the power generation systems installed in Europe are subject. To achieve the best possible benefit, it must be adapted to the local conditions of the individual countries.

Validity for most commercial systems

Against this backdrop, the VDE (German Electrical Engineering, Electronic, and Information Technology Association) has developed four national application rules for all voltage levels on behalf of the German Federal Ministry for Economic Affairs and Energy. As one of the directives, the VDE-AR-N 4110 “Medium-Voltage Technical Connection Rules” replaces the BDEW (Federal Association for Energy and Water Management) medium-voltage directive. Since April 2019, the VDE-AR-N 4110 has been mandatory for all newly commissioned power generation plants with a system output of 135 kW and a voltage range of 1 to 60 kV. The application rule therefore affects most commercial PV systems.

One aspect of VDE-AR-N 4110/20 deals with the mandatory use of only certified feed-in management controllers. The power control units ensure that the setpoints for the active and reactive power as well as the specified control procedures are followed at the grid connection point. The setpoints are determined either by third parties – the grid operator or direct marketer – via remote control technology or within the framework of characteristic curves that are defined in VDE-AR-N 4110/20.

Complete switchgear and controlgear assembly including a certified power control unit from Phoenix Contact

Certification of in-house solutions complex

The FGW TR8 must be used as the relevant directive for the certification of the electrical properties of power control units. The FGW TR3 must be used with regard to the measurement and test of these electrical properties. Finally, the modeling and validation of simulation models of the electrical properties is subject to FGW TR4.

The effort involved to obtain the so-called component certificate for PGS controllers is intensive, both in technical and financial terms. Particularly in photovoltaics, with a highly fragmented market in Germany, the certification of specially developed controllers will not be worthwhile for the majority of system installers. One aspect that should be at least as important as conformity with the connection directive is the flexible use of the controller.

Several functions in just one device

Against this backdrop, even before certification, Phoenix Contact addressed the question of how, on the one hand, conformity with standards can be ensured without the various possibilities offered by the industrial controller on which the solution is based. This is because the current PLC generation based on open PLCnext Technology is used as the hardware.

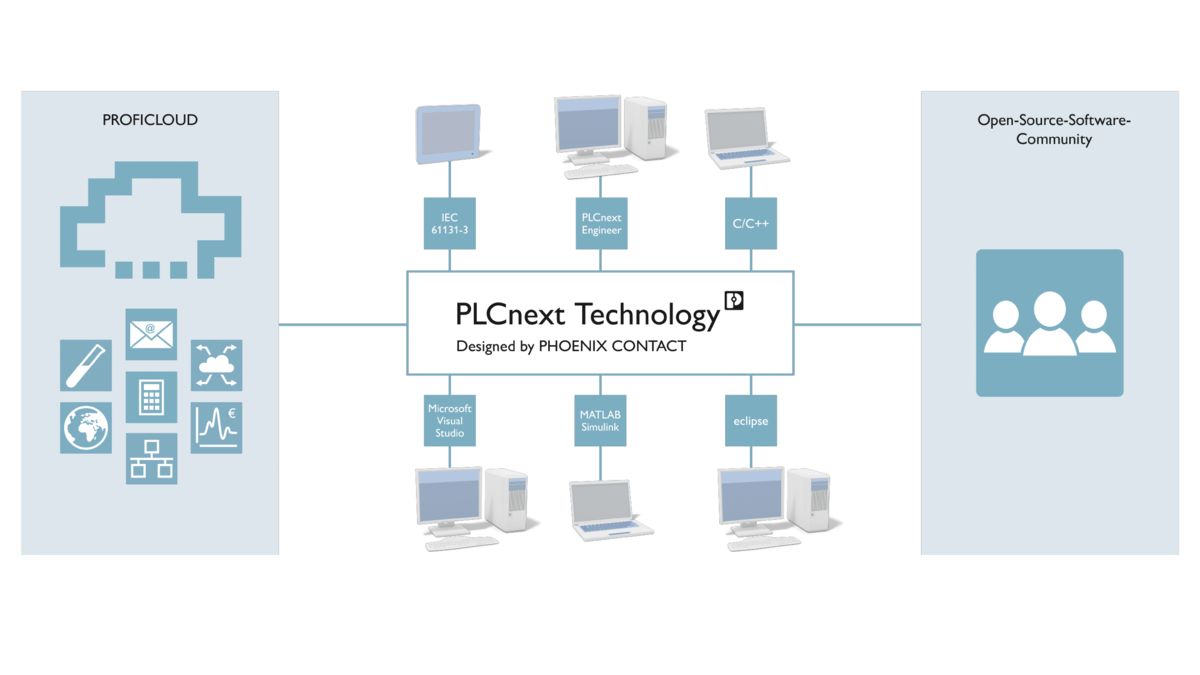

The technology not only enables the use of different programming languages – such as IEC 61131, C/C++, C#, and Matlab Simulink – in one project. Various functions can also be combined in one device. Phoenix Contact does not provide the user with an all-in-one solution, but specifically addresses users who have the necessary system and programming knowledge for their application. In initial projects, for example, a remote control connection was implemented on the same industrial controller in addition to the certified control function. Such an approach is cost-effective and space-saving, since two separate devices would normally be used for this task.

The PLCnext Control enables the development of program code with different software tools and even parallel execution on the device

Application example for easy commissioning

To support customers during the commissioning of the solution described above, Phoenix Contact provides an application example for coupling the remote control technology including a web application for configuring the power control unit. With the exception of implementing the respective requirement-specific interfaces, no further adjustments need to be made. However, additional functions can be added as needed. The control mode, the configuration of the standard PID controller parameters, the setting of characteristic curve interpolation points, the storage of bit patterns for the ripple control receiver, and the recording of all essential network and controller parameters during initial commissioning are part of this application.

Phoenix Contact also offers additional function block libraries for implementing the requirement-specific interfaces of the power control unit. Among others, these include modules for integrating decentral systems via remote control technology. In addition, photovoltaic-specific function modules simplify communication with inverters, energy meters, and the connection to a manufacturer-independent portal.

Connect with our experts

More posts

Clean water for Lake Constance

Innovative solution for clean water in Lake Constance and efficient pump monitoring.

Combatting cybercrime with full wind power

With effective security solutions, Phoenix Contact protects wind turbine turbines and other renewable energy generators against cybercrime.

Green energy with security

Hauke Kästing and Phoenix Contact protect wind turbine generators against cybercrime.