Energy storage systems connect sectors, but what connects energy storage systems? The importance of innovative connection technology for the safe operation of energy storage systems and for the realization of the All Electric Society.

Brief summary

Stationary energy storage systems are an essential link for sector coupling. The safety and reliability of these systems depends not least on the electrical connection technology used. This ensures interference-free power and data transmission.

Energy storage in the All Electric Society

Mitigating climate change and decreasing geopolitical dependencies are among the important issues of our time. The idea of an All Electric Society with sector coupling provides solutions. It is about networking our society, buildings, production facilities, mobility, and infrastructure through energy and information technology. In the All Electric Society this is achieved using renewable sources of energy that are available on an unlimited basis and do not produce harmful emissions.

Wind power and solar power are not available on a constant basis. However, modern society has a constant hunger for energy, 24 hours a day. Stable supply can only be achieved if surplus energy is stored in sufficient quantities so that it can be made available again at a later time, when it is required – for example, using battery energy storage systems.

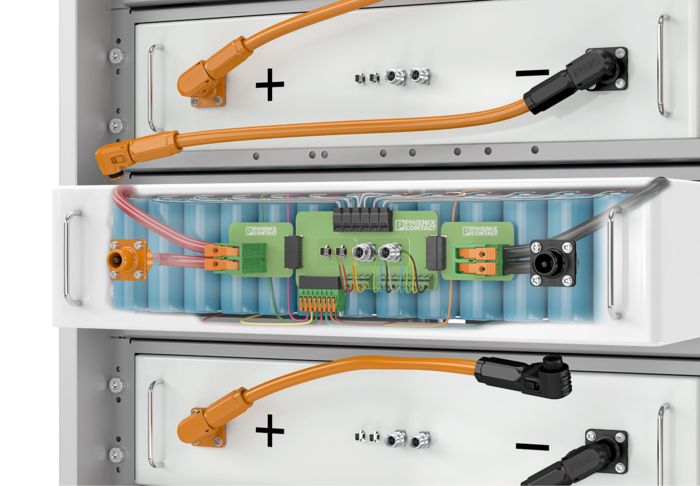

Battery module with battery cells and balancing PCB

Structure and method of operation

Depending on the capacity, these stationary systems can be installed in device housings, control cabinets, or even containers. However, the basic modular structure is always similar. There are three different types of electrical connections: the power connection, the signal connection, and the data connection, which are equivalent to the transmission of energy flows, of analog signals for monitoring and control, and of digital signals.

The smallest unit of a battery energy storage system is the battery cell, the actual storage element. Many of these cells are combined in a battery module and interconnected electrically (power). An electronic circuit ensures a balanced state of charge/discharge of all cells. This is referred to as cell balancing (signals). Temperature sensors monitor the thermal behavior of the cells (signals).

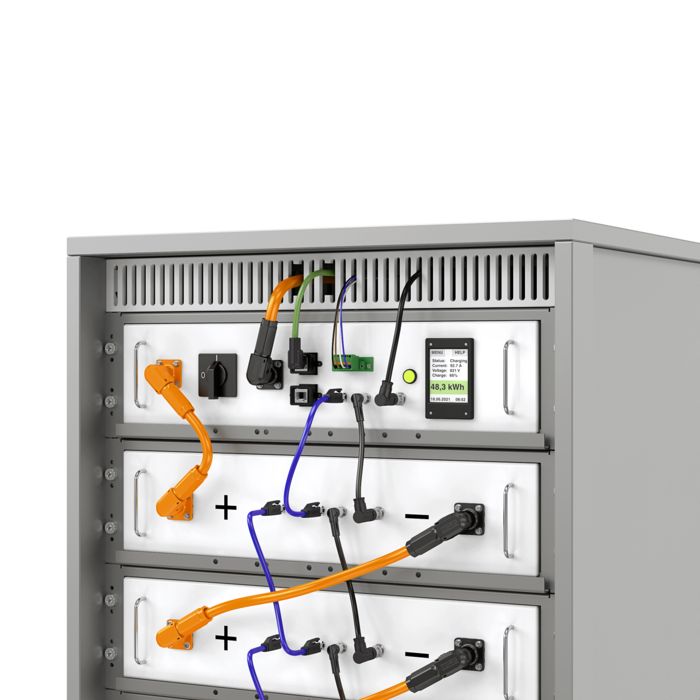

Battery rack consisting of a power control unit at the top and several battery modules

Several battery modules are combined to create a storage cabinet and connected at power level. All of the modules exchange information (data) with one another and with the control unit of the storage cabinet, known as the power control unit (PCU). So that external sensors can be connected, for example, both the battery modules and the PCU also often have signal interfaces, in addition to the power and data connections.

Modular structure of the energy storage system

In the system, several storage cabinets are interconnected at the three aforementioned levels: power, signals, and data. The higher-level controller at the highest level represents the system management. All the electrical connections of the storage cabinets converge again here. It also includes the external interfaces of the energy storage system. Energy is exchanged with the grid by means of power electronics. Signals from various auxiliary units converge in the system management, for example, for the fire extinguishing system. The system management communicates with the grid operator and service providers, who are able to access the storage system, via corresponding data connections.

Cardiovascular system of the energy storage system

Figuratively speaking, the electrical connections within the energy storage system can be described as its cardiovascular and nervous system. Energy flows represent the circulatory system via which vital energy is transported, signals represent our senses – such as for temperatures, gases, and visual impressions. The data lines are used to exchange information, just like nerves. If something is not right with your circulatory system or nervous system, you become unwell. The same is true in an energy storage system. Faults in the electrical connections result in system malfunctions and failure, and in certain constellations the entire system could even be destroyed.

Examples of faults in the connection technology

Three examples illustrate just how important connection technology is, starting with the power wiring:

-

In many cases, a classic screw connection is used to connect battery modules at power level. Screw connections can come loose when conditions are unfavorable. If not connected properly to begin with or during subsequent maintenance, this leads to increased contact resistance. At best, this manifests itself in heat loss; however, in the worst-case scenario, excessive overheating can actually cause a fire in the storage system and destroy it completely.

-

A typical signal connection is the connection of a current sensor cable to a printed circuit board. These connections are often soldered directly, which in conjunction with free cable ends entails the risk of so-called cold solder points. This results in incorrect signal information, such as current measurements being too low. As a consequence of this, excessively high charging and discharge currents would result in significant premature aging of the battery.

-

Data connections are often created using patch cables, that is to say, plug-in cables. If you do not pay attention to the quality here – for example, tight dimensional tolerances and high-quality contact surfaces – faults can occur during data transmission. These result in system malfunctions or even system failure, and at worst can even damage the hardware.

Innovative connection technologies for power, signals, and data for use in energy storage systems

Recommendations for selecting connection technology

For anyone who operates energy storage systems, the faults described always ultimately result in financial losses. So how can you avoid them? For power connections, plug-in connectors should be used whenever defined installation conditions cannot be ensured. This therefore applies to power connections that must be established during installation and maintenance.

When connecting free cable ends to printed circuit boards, innovative connection technologies are better than soldering. Insulation displacement connections, for example, do not require any pretreatment of the conductor end and – like spring connection technologies – offer a high level of convenience and maximum reliability. In the case of data connections, the requirements are defined by the ambient conditions. IP-protected data connectors are therefore ideal for high pollution degrees or humid environments, while industrial-grade data connections should be used in the case of tough mechanical conditions.

Summary

When it comes to energy storage systems, skimping on the initial investment ends up being costly during operation. In addition, these devices and systems are often operated in system-related applications. Reliability is therefore an important factor in realizing the vision of an All Electric Society. Electrical connections play a decisive role here. So they should be given the proper attention they deserve.

Connect with our experts

More posts

Battery storage system as a functional booster

Phoenix Contact uses open control technology to close the gap between power generation, storage, and further use.

Green energy with security

Hauke Kästing and Phoenix Contact protect wind turbine generators against cybercrime.

DC grids for sector coupling

E-mobility, solar systems, and battery storage systems are revolutionizing industry.