product line COMBICON Connectors S

cross section 1.5 mm2

connection method Push-in spring connection

type of packaging packed in cardboard

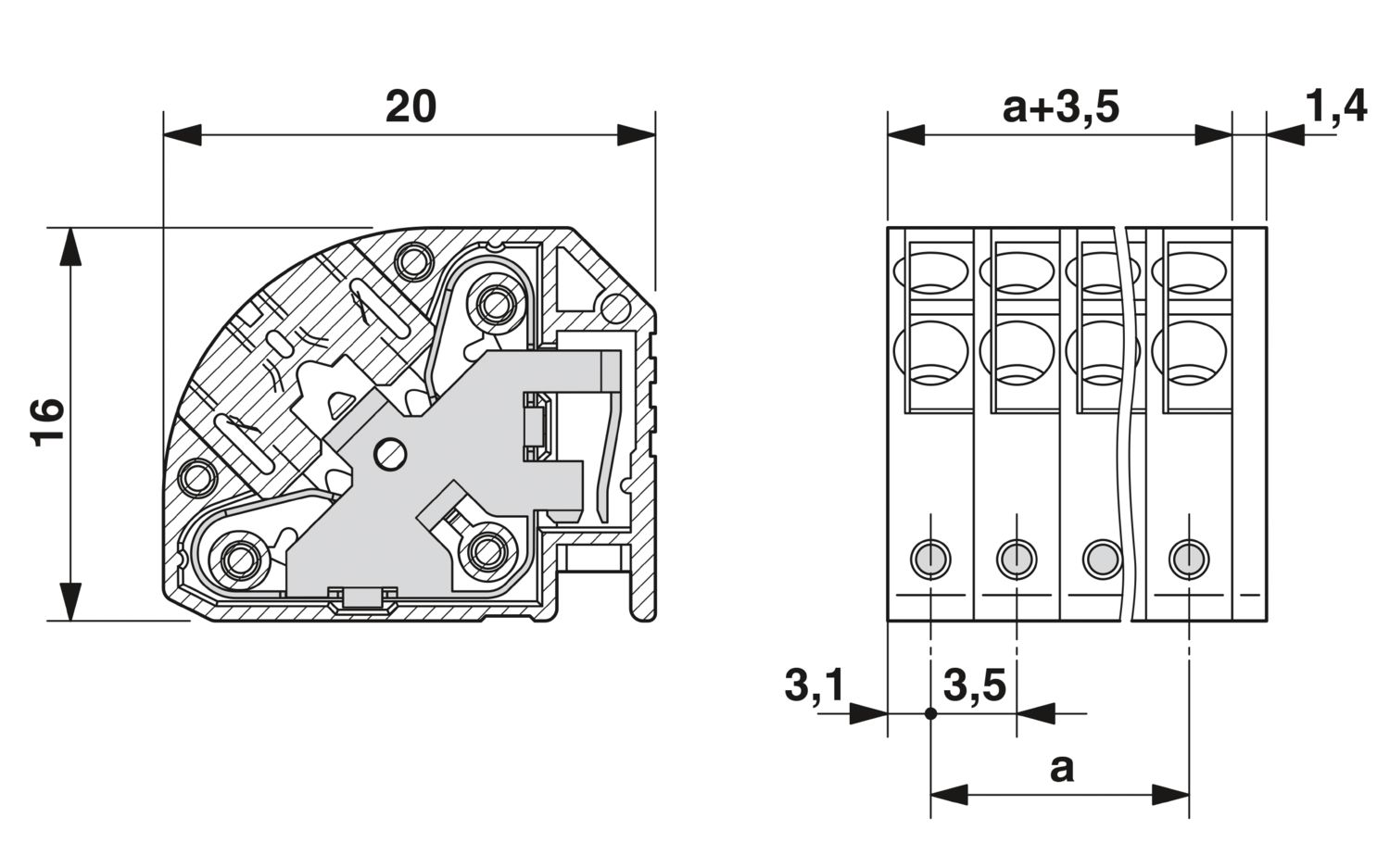

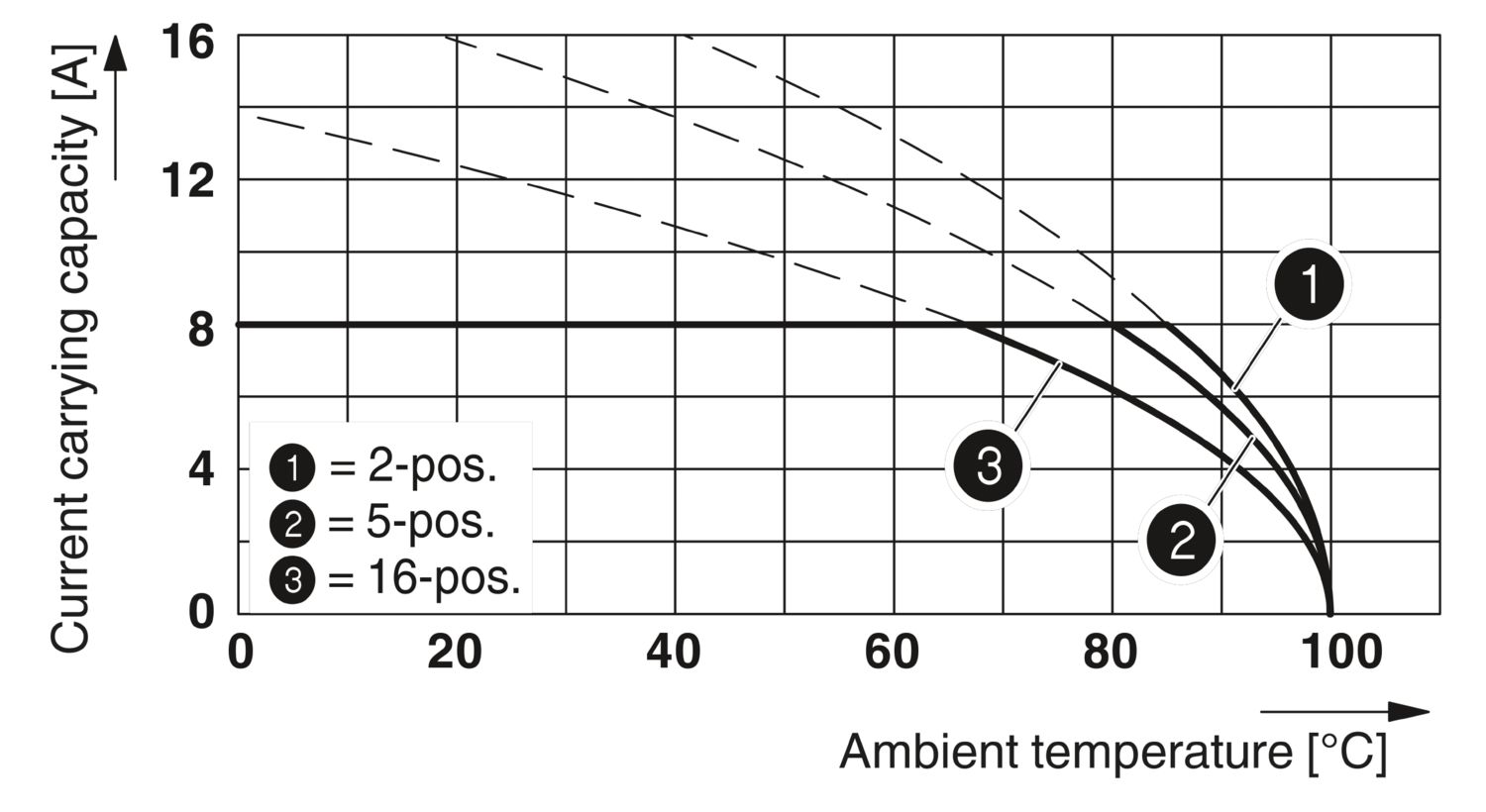

PCB connector, nominal cross section: 1.5 mm2, color: green, nominal current: 8 A, rated voltage (III/2): 240 V, contact surface: Sn, contact connection type: Socket, number of potentials: 10, number of rows: 1, number of positions: 10, number of connections: 20, product range: PTDA 1,5/..-PH, pitch: 3.5 mm, connection method: Push-in spring connection, conductor/PCB connection direction: 45 °, pin layout: Linear double pinning, plug-in system: COMBICON PST 1,0, locking: without, mounting method: without, type of packaging: packed in cardboard