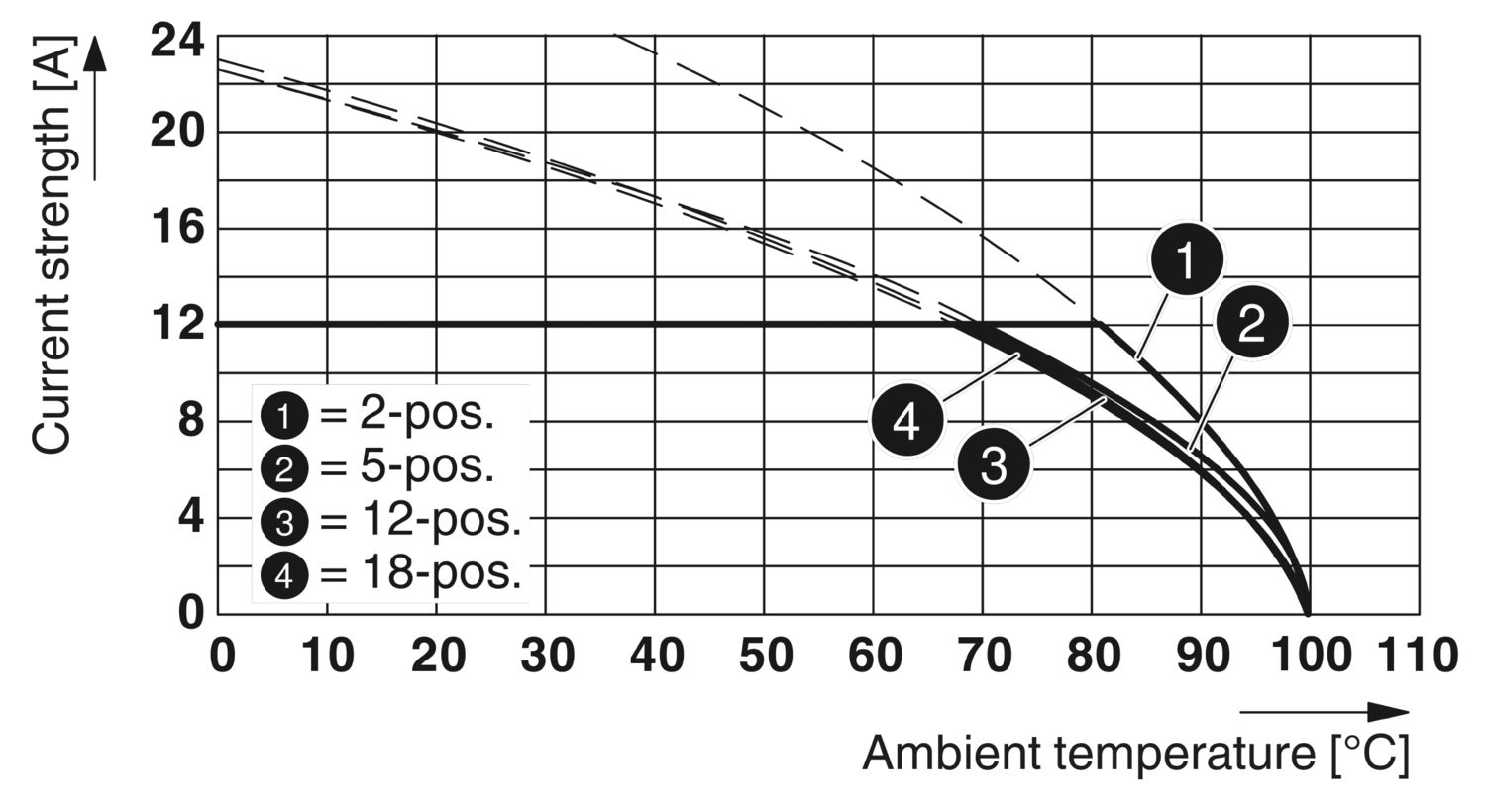

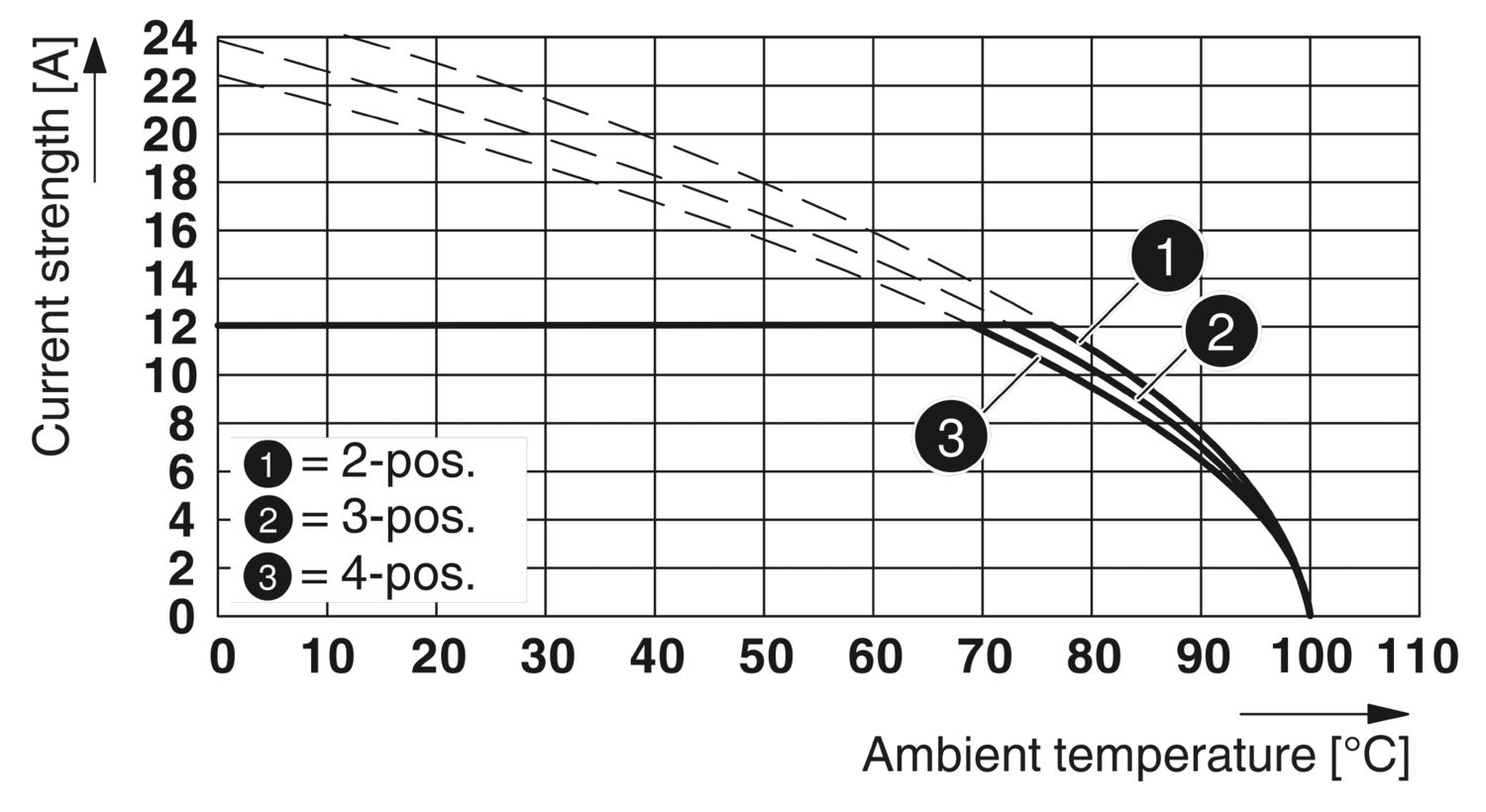

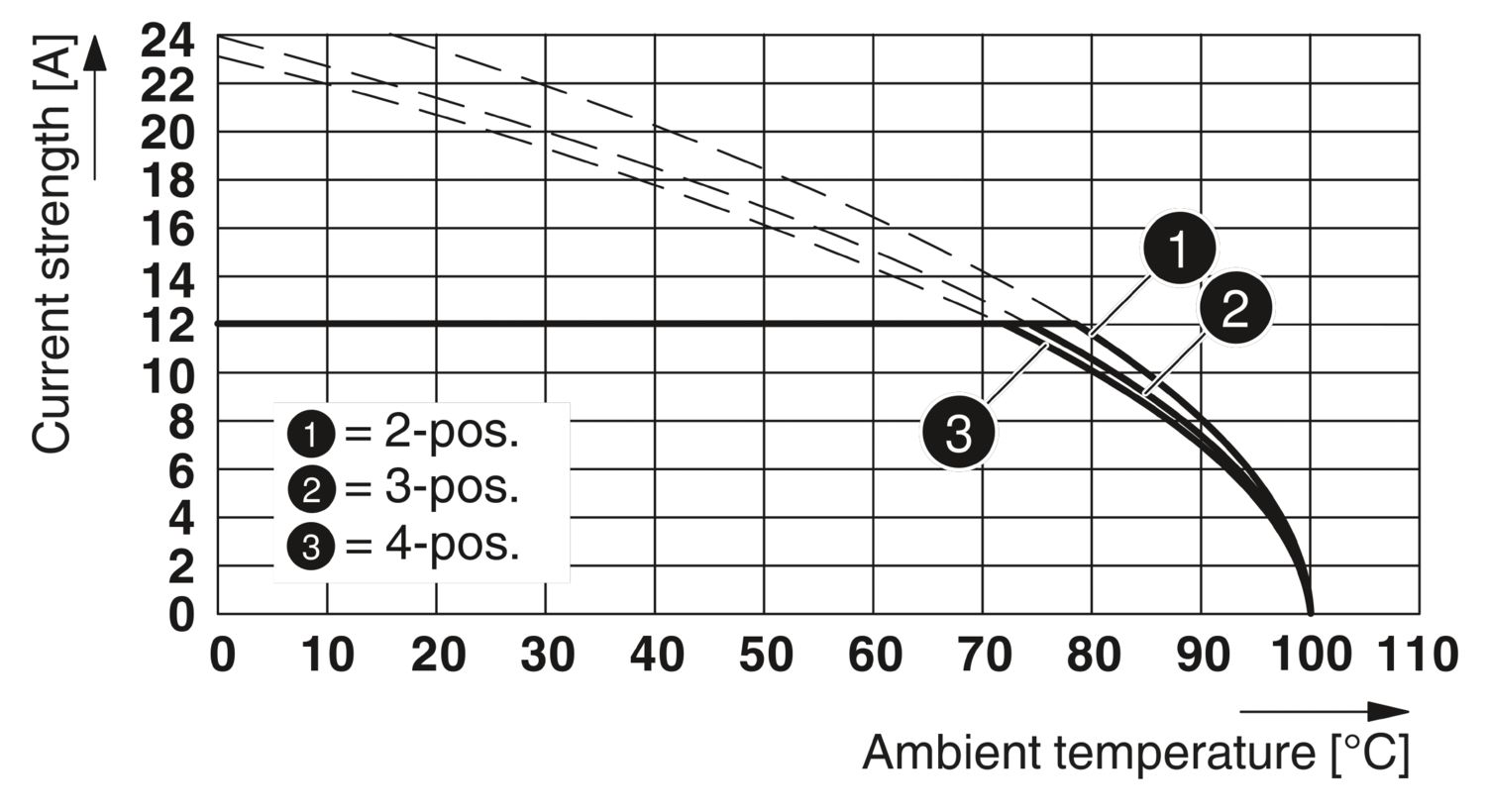

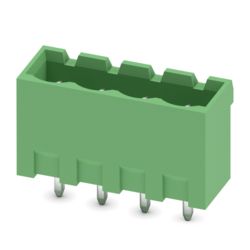

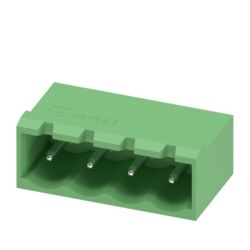

PCB connector, nominal cross section: 2.5 mm2, color: green, nominal current: 12 A, rated voltage (III/2): 320 V, contact surface: Sn, contact connection type: Socket, number of potentials: 4, number of rows: 1, number of positions: 4, number of connections: 4, product range: MSTBTP 2,5/..-ST, pitch: 5 mm, connection method: Screw connection with tension sleeve, screw head form: L Slotted, conductor/PCB connection direction: 0 °, locking clip: - Locking clip, plug-in system: COMBICON MSTB 2,5, locking: without, mounting method: without, type of packaging: packed in cardboard