PROJECT complete planning software Process innovations for control cabinet manufacturing.

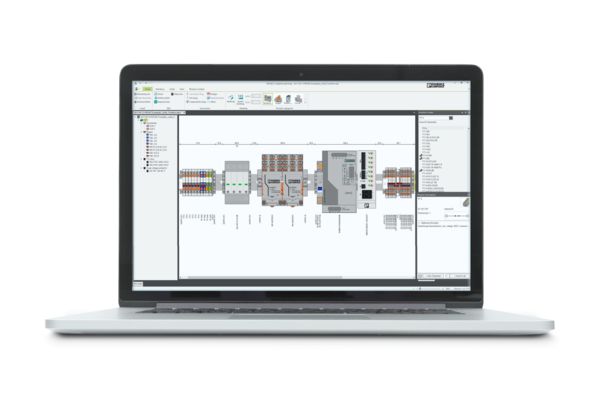

PROJECT complete combines our proven planning software for terminal strip configuration with a high-performance marking tool. Direct data exchange with all conventional CAE programs, along with the creation of the complete project documentation, make this configuration software unique.

Planning and marking software

Configuration and marking with a single piece of software

PROJECT complete enables you to configure and document your terminal strips by means of direct CAE data exchange and then create your marking. The software supports you with an auto-correct function and is compatible with all of our products, marking systems, and marking materials.

- User-friendly operation, thanks to data transfer from the CAE program

- Complete documentation including order, assembly, layout, and parts lists

- Auto-correct function for error-free layout

- Always up-to-date, thanks to online update of material data

- PROJECT complete controls all printing systems from Phoenix Contact, as well as standard printers

PROJECT complete – continuous flow of data along the entire value added chain

If customized terminal strips can be manufactured cost-effectively in a batch size of 1 using flexible production facilities, a great deal of potential can be exploited in control cabinet manufacturing. Suitable software solutions are therefore a key factor in success when developing such manufacturing systems.

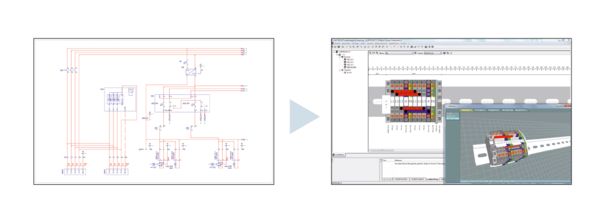

The PROJECT complete configuration software from Phoenix Contact creates the interface for data flow along the entire value added chain – from CAE level right through to automated production.

By exporting production orders in Automation ML data format, the PROJECT complete software acts as the interface between control cabinet configuration and automated terminal strip production.

The PROJECT complete planning tool converts the virtual connection points from the CAE system into the appropriate terminal blocks.

Automatic Push-in terminal strip production with the clipx machine at Krones AG

More efficient planning and manufacturing with intelligent configuration software

Continuous data flow – from planning right through to manufacturing – is becoming ever more important for companies due to advances in digitalization. This topic also plays a crucial role in control cabinet manufacturing. Especially when it comes to the project-specific configuration of terminal strips.

For this reason, PROJECT complete provides users with the option of exporting their complete production orders in Automation ML data format. The intelligent configuration software therefore enables significant increases in efficiency along the entire value added chain – from planning right through to automated manufacturing.

Consequently, a growing number of companies, like Krones, are already turning to automated manufacturing solutions.

Terminal strip service

Order terminal strips directly from the software

The choice is yours: Use PROJECT complete to produce your own individual terminal strip including marking or send your order directly from the software and submit it online.

We will then assemble, wire, and mark the terminal strip according to your specifications. Quick and easy – all you need to take care of is installation.